Stationary Concrete Pump

Applying a stationary concrete pump for building construction is investing for an increased profit in both short and long terms!

Luton’s concrete pump is perfectly designed for every building site application. It handles long-distance concrete conveying and saves your money and time greatly!

High-Pressure Pump

Small and Compact Design

Reach out to us to get a free quote!

Popular Stationary Concrete Pumps for Sale

Hot selling models

HBTS 30

| Model | HBTS 30 |

| Max. Output capacity (m³/h) | 30 |

| Max.Concrete Pumping Pressure (Mpa) | 10 |

| Max. Horizontal Conveying Distance (m) | 450 |

| Distribution Valve Type | S Valve |

HBTS 40

| Model | HBTS 40 |

| Max. Output capacity (m³/h) | 40 |

| Max.Concrete Pumping Pressure (Mpa) | 10 |

| Max. Vertical Conveying Distance (m) | 800 |

| Distribution Valve Type | S Valve |

HBTS 60

| Model | HBTS 60 |

| Max. Output capacity (m³/h) | 60 |

| Max.Concrete Pumping Pressure (Mpa) | 13 |

| Max. Vertical Conveying Distance (m) | 1, 000 |

| Distribution Valve Type | S Valve |

HBTS 80

| Model | HBTS 80 |

| Max. Output capacity (m³/h) | 88 |

| Max.Concrete Pumping Pressure (Mpa) | 16 |

| Max. Vertical Conveying Distance (m) | 1, 200 |

| Distribution Valve Type | S Valve |

Get the Best at All Levels In Luton

Why choose Luton?

Supporting customize your own Pumps

Delivering the pump to you quickly

Offering helps to choose static pumps

Providing full parts and pipelines for use

Instructing you to install and operate the pump

Solving your problems online all the time

You will enjoy the best after-service here in Luton. Service is not an option but a necessity, a worse after-sale service costs you more.

We have teams in some countries and will appoint the expert to your place, so all the installation and maintenance will never bother you.

OUR PARTNERS

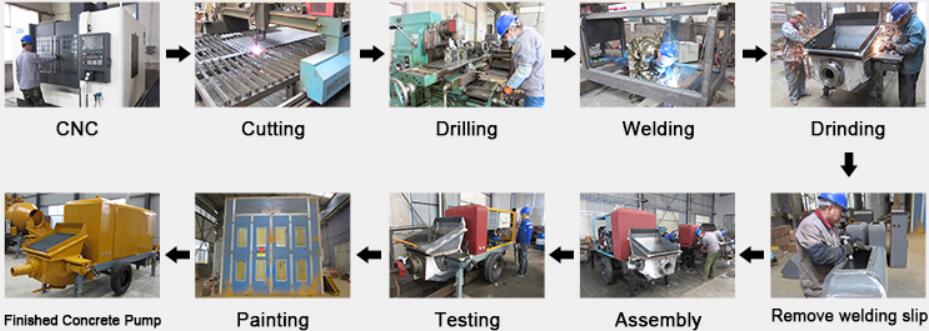

Stationary Concrete Pumps Producing Process

Tested and trusted quality

We strictly supervise every step in the whole producing process and we have exported our 7,000 + stationary concrete pumps to 100+ countries and cooperate with 80+ famous partners, owns 20+ honors and patents.

Competitive Advantages, Reasonable Price

With 22 years of R & D in the construction field, Luton’s stationary concrete pump shows competitive advantages in each part.

1. High power of the motor to match hydraulic and pumping system to promote efficiency.

2. Automatic lubrication to ensure each part can be centralized lubricated with enough oils evenly to maximize the effect.

3. Germany-made components ensure high quality to prolong the service life and prevent errors.

4. Simpler operation to save much time on figuring out how to use it, and enures safety owing to the high ad low voltage switch.

5. Excellent after-service to solve all your problems and eliminate the troubles on installing and maintaining.

6. Reasonable price to maximize your profits. You need to know that the cheapest pump doesn’t mean the lowest cost. Worse transportation and after-sale may even cost you more!

Choose Luton to get the best pump and considerate service!

Stationary Concrete Pumps for an Increased Profit

A stationary concrete pump is also called a static concrete pump and trailer-mounted concrete pump, which pumps and conveys concrete to the target place.

You may know that the installation time and preparation time is longer including mixing concrete in advance, but once it is ready, the pouring and transporting time will be much faster than labor work.

A static pump is the best choice for residential jobs for sure, but it handles commercial projects very well too. For larger structures, a stationary concrete line pump with a larger concrete output is necessary, 50 m³/h above is able to complete the middle size construction such as new rural house buildings.

If you are a business contractor, getting Luton’s stationery pump gains a high return rate. Not like other truck boom concrete pump that takes up large space, expensive, and require high maintenance costs, the static ground pump is very easy to maintain.

As a kind of investment mechanical equipment, concrete trailer pump is undoubtedly the equipment with the least investment risk but high return among all the investment construction equipment.

Also, small concrete pumps have low capital costs and a short product payback period. They are suitable for lease financing and are trustworthy.

How to Get Stationary Pumpcrete?

Step 1

Before pumping concrete, pump water to lubricate the pipes, check whether the pipe clamps are sealed and leaking, and then pump mortar to the pipes.

Step 2

If you need to stop the pump, press “Pumping start and stop” first, and then press “Oil pump start and stop” to stop working.

Turn on the power switch after turning on the power. Press “Oil pump start and stop” to start the oil pump, and then press “Pumping start and stop” (pumping start and stop is to control the machine’s outward pumping action).

Step 3

When the concrete in the hopper leaks out of the S pipe during work, it is necessary to stop working and continue after adding concrete. The machine cannot be evacuated, otherwise, it will easily cause pipe blockage.

Step 4

During the pumping process, pay attention to the pressure gauge. If the pumping pressure suddenly rises, you should immediately turn on the reverse pump button, reverse the pump for 2-3 strokes, and then forward the pump.

If the pumping pressure is still too high at several consecutive times, it means the pipeline is blocked.

Get A Free Quote

Mobile:

0086-173-2016-6678

Whatsapp:

0086-173-2016-6678

Email:

sales@ltconcretepump.com