Concrete pump hydraulic system is one of the core parts of concrete pump. With the modern construction industry developing more and more fast around the world, concrete pump has become the irreplacable and efficient concrete treatment onsite.

Why the concrete pump is so high efficient perfromance, low economical cost and so flexible mobility ? One important reason is that it has a powerful stable hydraulic system. Let’s walk into the interior of LUTON concrete trailer pump to find out the answer closely!

Strong Power – Excellent and Reliable

Smooth Control – Precise and Stable

Optional Pressure Mode – Flexible Site-Suitability

Rubber Hose

MALULI (Italy)

What Is Concrete Pump Hydraulic System

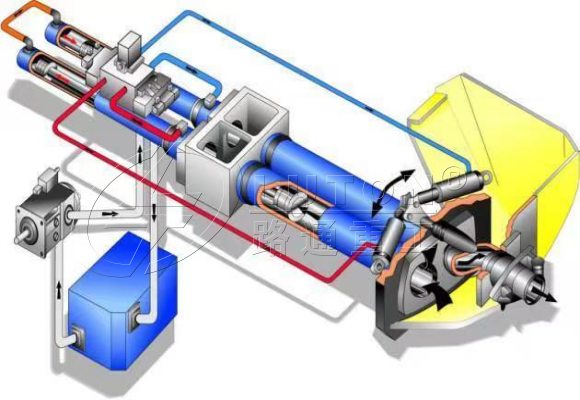

Concrete pump hydraulic system is one of the important core driving system. It is the direct power source to realize the concrete cylinder piston pumping function, the driving power of S valve swing, the direct source of rotary mixing of concrete mixing shaft, and so on.

In the process of concrete pump work, the original energy from diesel engine or motor, goes through hydraulic pump and gear pump into continuous and stable hydraulic energy. Through the solenoid block control power adjustment (direction, pressure, etc.), after the hydraulic motor, hydraulic energy goes directly to drive the execution unit to realize the hydraulic cylinder piston acting, S valve cylinder swing, the rotating of the hopper mixing shaft function. So as to complete the flow of concrete pump.

What Are The Main Components Of Hydraulic System

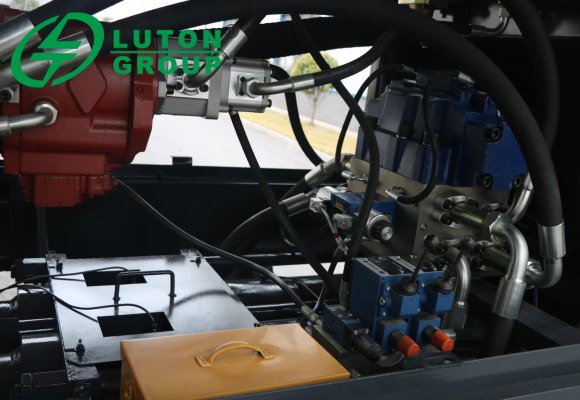

Take LUTON concrete trailer pump as an example, the hydraulic system is mainly composed of power unit, control unit, oil box, pipeline and other auxiliiary components.

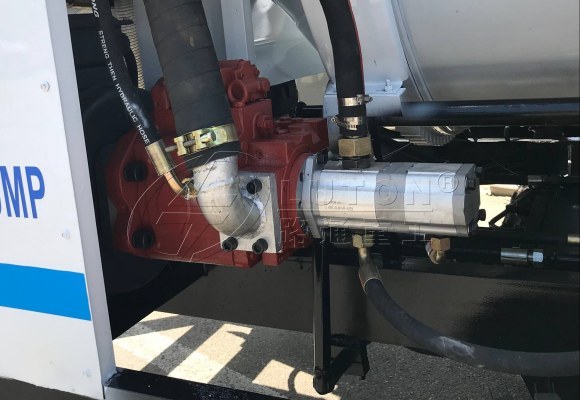

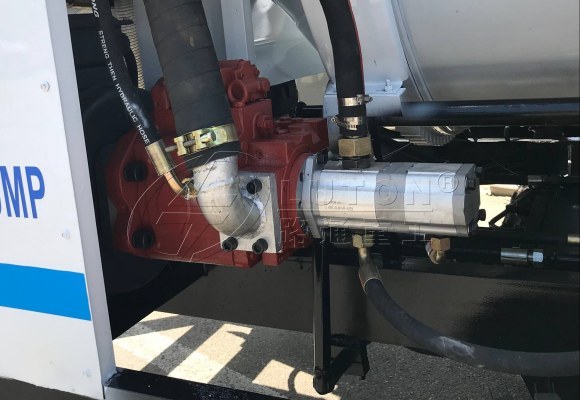

The power unit refers to the main hydraulic pump and other gear pumps, which mainly converts the mechanical energy from the diesel engine or electric motor into the continuously stable and easy-control hydraulic energy. At the same time, the energy is divided into different parts for use by each executive system.

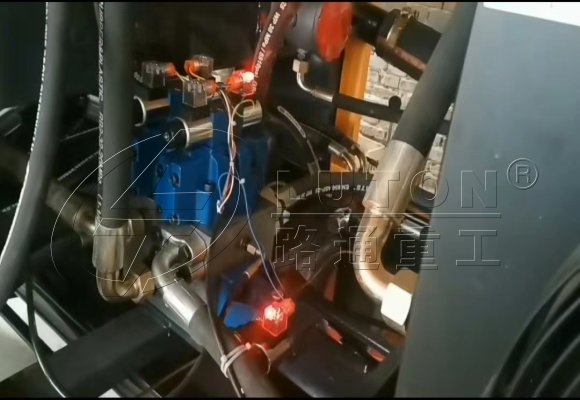

The control unit is mainly composed of the solenoid control valve blocks, which is used to control the change direction of the main hydraulic cylinders and the S valve swing cylinder, the rotation direction of the hydraulic motor in mixing unit, the value of the hydraulic pressure of each part, and the switching between high and low pressure pumping modes.

The hydraulic oil tank is also an importan part of the hydraulic system in concrete pump. Not as simple as a sound box filled with oil, it is a fully functional hydraulic oil storage system including oil temperature detection, oil filtration, liquid level display and oil quality observation.

What Are The Types Of Concrete Pump Hydraulic System

The hydraulic system of concrete trailer pump includes pumping system, swing system, mixing system, while the hydraulic system of concrete pump truck also includes boom placing rod system, supporting leg, rotating and auxiliary system and so on.

The most important and core part of concrete pump hydraulic system is the pumping system, so the type of hydraulic system is also divided according to the types of pumping system.

There are two different types in pumping system, open-circuit type hydraulic system and closed-circuit type hydraulic system. At present, in the global concrete pump market, the open-type hydraulic system is used in most of concrete pump products.

Open-circuit Hydraulic System

In the open-circuit hydraulic system, the hydraulic pump absorbs oil from the oil tank, and supplies to the hydraulic actuator (hydraulic motor or hydraulic cylinder) through the valve to drive the working mechanism. And the return oil of the actuator (or hydraulic motor) flows into the tank. The oil tank of this hydraulic system connects the inlet of the pump and the outlet of the actuator to compensate and balance for the hydraulic oil volume change in the pipeline system and the actuators. And help the heat dissipationg of the hydraulic system.

The typical representative of the open-circuit system is the pump products of Schwing Company.

Close-circuit Hydraulic System

The oli circuit of the closed-loop system is a closed circuit. Compared with the open circuit system, the loop is more complex. The closed-loop system with small power consumption, stable change and small impact is widely used in large flow system.

However, the oil outlet of the actuator is directly connected with the oil inlet of the hydraulic pump, the oil outlet is not connected to the oil tank, and the hydraulic oil temperature changes greatly, so it is suitable for the system with less heat.

PUTZMEISTER’s products are typical of the closed-loop hydraulic system.

How Does A Hydraulic Concrete Pump Work

A hydraulic concrete pump working process is a whole-systems-cooperating work process.

In this process, each part of concrete pump performs its own duty, issues different actions according to the control instructions, to complete the whole pumping task. These function parts are respectively, power system, hydraulic system, control system, pumping system, mixing system, cooling system, lubrication system and so on.

Power system provides a strong and reliable power source, usually diesel power or electric power. LUTON has many options for concrete diesel engines, WEICHAI, YUCHAI, CHANGCHAI, YUNNEI, etc. All these are China’s first-class engine brands.

Diesel engine or electric motor provides a steady stream of mechanical power to the hydraulic system, through the hydraulic pump, the gear pump, which is converted into the hydraulic energy. That is steady and continuous, easy to control for driving each partial actuator (hydraulic cylinder rod of pumping system, hydraulic motor of mixing system, swing cylinder of S valve system, etc.)

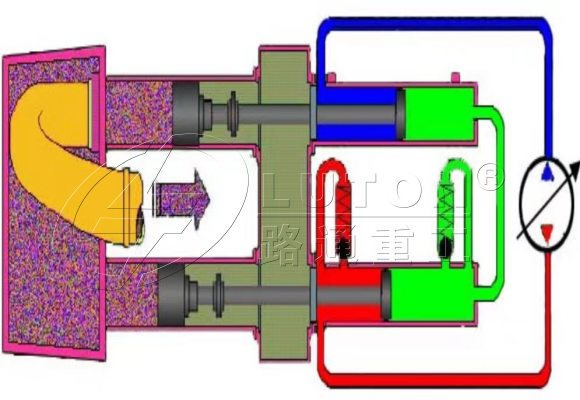

Consider the pumping process. Usually, our pumping system adopts the form of double-row piston-type hydraulic cylinder working alternately.

Step1

In the initial state, the piston of the hydraulic cylinder1 is located at the starting end of the cylinder. When the piston is at the starting port, the detection signal triggers the action of the valve block of the control system, and causes the S valve to swing to connect the concrete cylinder outlet with the pump body outlet.

At the same time, the hydraulic oil with high pressure flows out of the main hydraulic pump, and through reversing control. It enters from the starting end into the hydraulic cylinder1, pushing the piston forward. Furtherly, the connecting rod in the hydraulic cylinder push the piston in the concrete cylinder forward. Finally, push the concrete out from the outlet of the pump body.

Step2

When the piston is moved to the detection position of the end of hydraulic cylinder, the solenoid valve control system is triggered again to change the direction. And the swing cylinder moves again to drive the S valve to connect the concrete cylinder outlet with the cconcrete hopper.

At the same time, the flowing direction of the high pressure hydraulic oil is changed by the control system. It flows in from the end of the hydraulic cylinder, pushes the piston reversly, and move the piston in the concrete cylinder to the starting position.

Meanwhile, the concrete in the hopper will enter into the concrete cylinder through the S valve, until the hydraulic piston returns to the initial position again. The concrete fills the whole concrete cylinder and waits for the next solenoid valve moving to pump the concrete out.

Step3

This is the complete pumping cycle of hydraulic cylinder 1. The other cylinder, hydraulic cylinder2 works according to the same pumping principle. The two cylinders work alternatively under the control of the main solenoid valve block. Finally achieve the continuous output of the entire concrete pump.

What Is The Hydraulic Pressure Of Concrete Pump

The hydraulic pressure of concrete pump refers to the hydraulic oil pressure of the concrete pump, including the oil pressure of the main pumping system, the distribution valve system, the mixing system, and the swing cylinder system etc. The most important among them is the oil pressure of the main pumping hydraulic system, which directly affects the output pumping pressure of the concrete pump, and also determines the final pumping capacity of the pump. The following is the list of hydraulic system pressure and pumping pressure of LUTON GROUP concrete pump in stadard configuration.

| Model | Max.concrete pumping pressure (MPa) | Pumping System Hydraulic Pressure(MPa) | Mixing System Hydraulic Pressure(MPa) | |

| Diesel Concrete Trailer Pump | HBT30-6-52R | 6 | 26 | 6 |

| HBT40-10-82R | 10 | 31.5 | 6 | |

| HBT50-10-92R | 10 | 31.5 | 6 | |

| HBT60-13-129R | 7/13 (Low/High) | 31.5 | 6-8 | |

| HBT80-16-176R | 7/16 (Low/High) | 32 | 6-8 | |

| HBT90-22-199R | 20/14 (Low/High) | 32 | 8 | |

| Electric Concrete Mixer Pump | JBS30-10-37 | 10 | 28 | 6-8 |

| JBS40-10-45 | 10 | 28 | 6-8 | |

High- and Low-pressure Concrete Pump

As we all know, the feeding height and distance of the concrete pump depends on the pushing force of the concrete piston, and the pushing force depends on the pressure on the piston of the main cylinder where the hydraulic system acts. This pressure is the hydraulic pressure of the pumping system.

High pressure or low pressure pumping modes of concrete pump are realized by the high and low pressure of the hydraulic system.

Hydraulic system high or low pressure, simply say, is due to the different action are of hydraulic oil pressure in the main cylinder.

When the hydraulic system works in the low pressure state, the concrete conveying pressure is relatively low, the pumping speed is fast, the pumping capacity is also large, more suitable for the fast and large amount of concrete conveying tasks.

When the hydraulic system is working in high pressure state, the conveying pressure of concrete is also higher, and the pumping speed and pumping capacity are lower, which is more suitable for the delivery of concrete to higher and longer distance.

Usually, during the working process, in order to increse the pumping efficiency, we often make the pump working at low pressure mode.

In this state, when conveying concrete to higher and farther places, the pressure of the hydraulic system will increase with the increasing transmission resistance. And when a certain critical value is reached ( reference value 25MPa) , it will cause pipe blokage. At this point, switching a high pressure state should be a good choice.

This way not only can achieve high efficiency, but also ensure the super long or high distance. This is a very flexible conveying method.

Concrete Pump Hydraulic System Manufacturers

The core of the concrete pump hydraulic system is the main hydraulic pump. Different hydraulic pump manufactruers all over the world, continously efforting, pioneering and innovating, are all trying to contribute to the global market with better performance, more durable, less fuel consumption, less heat hydraulic pump boutique.

Rexroth (Germany)

The subsidiary of German industrial giant Bosch Group, focuses on providing hydraulic, electronic transmission and control products and services for all kinds of mechanical products around the world.

At present, most of the core components of excellent concrete pump equipment-the main oil pump are rexroth products. Its stable performance and excellent quality directly affect the performance of the hydraulic system of the whole pumping equipment.

Kawasaki (Japan)

Kawasaki Heavy Industries, is one of the largest heavy industry groups in Japan. With a hundred years of development history, its main oil pump, constant pressure pump, solenoid valve and other products, are also widely used in all kinds of concrete pumping machinery and equipment, and the price is cheaper than Rexroth.

Parker (USA)

Parker is the world’s largest supplier of transmission control products and the world’s largest manufacturer of professional hydraulic joints and hose assembly. In terms of the technology and performance of the hydraulic parts, Pike has the strength of competing with Rexroth.

Eaton (USA)

Eaton is a century-old American brand, mainly engaged in the hydraulic and mechanical power field of product research and development. Its products have a strong strength in the military aerospace system fuel and hydraulic, as well as pneumatic system.

Hawe(Germany)

Harvey Hydraulic Co., Ltd. was founded in 1949, is a well-known brand in Germany, mainly engaged in the production and research of control valves. Its products valve body all steel structure, high pressure resistance, compact structure, small volume, no leakage, long service life, is widely used in engineering machinery, ships, hydraulic tools and other fields.

How Often Should Hydraullic Hoses Be Changed

Usually, the service life of the hydraulic hose is about 3-6 years. LUTON Concrete pump products use Italy MANULI hose, more high temperature and pressure resistance, more durable.

In daily maintenance, check the hydraulic hose and joint regularly to ensure whether there is oil leakage. If so, replace the hose in time.

The replacement steps are as follows:

- Turn off the machine and release all the residual pressure in the hydraulic system

- Carefully remove the hose joint, and then immediately plug the joint with an oil, do not let the dirt into the oil road, colleagues avoid the hose contact with the dirt.

- When installing the hose joint, make sure to place the sealing ring correctly. Ensure that the hose is not twisted and tensed and avoid bending and winding.

- Place the hydraulic hose freely, not friction with anything, there is enough space around the pipe, so that the use process is not affected by the vibration of the pipe.

- After reinstalling the soft hose, conduct a test run and check all the hydraulic oil discharged from the hose, collect in a container and dispose properly.

Concrete Pump Hydraulic Oil

Hydraulic oil in the concrete pump hydraulic transmission system as an intermediate medium, not only plays the role of transmitting and converting energy, but also plays the lubrication, corrosion prevention, cooling, washing and other roles between the internal components of the hydraulic system.

It is as the blood of the whole hydraulic system, affecting the stability of the whole system operation. The correct selection and use of hydraulic oil will have an important impact on the ability of the hydraulic system to adapt to the working environment, the service life of the system and components, and the reliability of the system work.

Under standard conditions, the hydraulic oil of LUTON concrete pump equipment usually uses Kunlun brand 46# anti-wear pressure oil.

The operating temperature is -10-70℃. If the equipment needs to be started at a very low temperature, the low condensate hydraulic oil must be selected.

Factors Affecting The Quality Of Hydraulic Oil

In the process of use, there are many factors affecting the quality of hydraulic oil, mainly water, impurities, air and so on.

If the water content is too high, it will cause the oxidation of hydraulic oil, cause oxidation precipitation, block the oil road, and affect the normal operation of the system. In addition, the oxidation of the oil will also produce a corrosive acid solution.

Impurities can not only accelerate the wear of the relevant moving parts, but also get stuck in the valve spool or other moving parts, affecting the normal operation of the system, leading to the failure of the machine.

When the hydraulic oil pipeline contains air, when the bubbles overflow, it will impact and cavitation on the pipeline and components, causing the system to work properly and damage the components.

Therefore, check the hydraulic oil before using the equipment.

First, checke the oil fluid if it contains water.

Take out 2-3ml of hydraulic oil and put it into the test tube, waiting for a few minutes to make the bubbles disappear. Then, heat the oil and listen to whether the mouth of the test tube sounds. If any, there is water.

Second, check the smell and appearance.

Comparing the new oil with the used oil, if the color varies greatly and it smells strange, replace the hydraulic oil immediately. If there is no obvious difference between color and smell, then place the two kinds of oil for one night and check. If the precipitation of the used oil appears on the bottom, filter the hydraulic oil and clean the tank before use.

Use of Hydraulic Oil For Concrete Pump

1.Check the oil level before starting up, and each oil circuit switch is in the correct starting state.

2.Set the engine on idling-speed state for about 5min, check for bubbles in the liquid level meter. It is normal for new machines and new hydraulic oil to have bubbles, which need to be used normally after the bubbles disappear.

3.Pay close attention to the oil temperature. After the machine works for a period of time, if the oil temperature is high, it is best to stop and rest for a while, and then work after the oil temperature is normal for extending the life of the system.

4.Filter the hydraulic oil regularly to keep the impurities within the allowable range.

5.Change the hydraulic oil regularly, and replace the oil filter simultaneously.