Concrete pump rates refer to the flow rate of concrete in the pumping pipe, which is an important parameter to measure the efficiency of concrete pumping. It is usually expressed in meters per second or cubic meters per hour, reflecting the flow behavior of concrete during pumping. Concrete pump rate of concrete not only affects the construction progress, but also directly affects the performance indexes of concrete such as uniformity, condensation degree and strength.

Wide Pumping Rate Range 10~100 m³/h

Smooth Concrete Pumping Performance

Suitable for Various Construction Projects

Stable Ensurance Of Efficient Production

Range of Concrete Pump Rates

The rate range of concrete pump varies with many factors such as pump type, pumping distance, pipeline conditions and concrete characteristics. The rate range of most concrete conveying pumps is between 10m³/h to 100m³/h, and majority of pump types can achieve two variable displacement or stepless variable to adapt to different construction needs. Generally speaking, the pumping rate of the low-pressure pump(≤5MPa) is relatively low (≤10m3/h), which is suitable for short-distance transmission (≤100m); The medium pressure pump (6-10MPa) has a moderate pumping rate (20-60m3/h), which is suitable for medium distance (100-200m) and a certain height (≤80m); The high pressure pump (>10MPa) has a higher pumping rate (80-100m3/h), which can meet the needs of long distance (≥200m) and high-lift distance (≥80m).

| Models | Concrete Pumping Rates | Description |

| Small Concrete Pump | ≤30m³/h | The pumping rate is relatively low, the specific value will vary according to the specific model and working condition. For example, some small concrete pumps rates may pump around 20m³/h. |

| Medium Concrete Pump | 30-800m³/h | Medium concrete pumps have a highwer pumping rate, which can meet the requirement of medium scale construction. For example, some medium-sized concrete pumps can convey 60-70 m³/h. |

| Large Concrete Pump | ≥800m³/h | Large concrete pump rate is high, suitable for large-sized projects and long distance pumping. For example, some large concrete pumps can pump concrete more than 100m³/h. |

Concrete Pump Rates Of Hot Models

HBTS40 Concrete Pump

Suitable for high-rise pumping and other scenarios

| Power Energy | Diesel / Electric |

| Range of Output Capacity | 40 m³/h |

| Distribution Valve Type | S valve |

| Max. Pumping Pressure | 6-8 Mpa |

| Diesel Engine Power | 82 KW From Yuchai/Weichai |

| Electric Engine Power | 45 KW |

| Max. Verticle Transportation | 120m |

| Max. Horizontal Transportation | 500m |

LT-10 Diesel Concrete Pump

Suitable for secondary structural projects and special construction.

| power | 18 kw |

| maximum aggregate | < 20 mm |

| vertical conveying height | 30 m |

| horizontal conveying distance | 80-100 m |

| transport capacity | 8-10 m3/h |

| pipe diameter | 80 mm |

| cylinder diameter*stroke | 120 mm*360 mm |

HBTS60 Concrete Pump

Suitable for large particle concrete transport, can transport stones within 5cm, vertical transport up to 80m, horizontal transport 200-300m.

| Power Energy | Diesel / Electric |

| Range of Output Capacity | 60 m³/h |

| Distribution Valve Type | S valve |

| Max. Pumping Pressure | 13 Mpa |

| Diesel Engine Power | 90 KW From Yuchai/Weichai |

| Electric Engine Power | 75 KW |

| Max. Verticle Transportation | 150m |

| Max. Horizontal Transportation | 400m |

Concrete Pump Truck

There are variety of displacement for different types of concrete pump truck. Generally speaking, the displacement of large pump trucks is great, so the transmission rate is relatively high.

| Max. Theo. Concrete Output | 85-200 m3/h |

| Vertical Height of Boom | 30m~61m |

| Turntable Rotation Angle | ±210° ~ ±360° |

| Max. Pumping Pressure | 7.5~10 MPa |

| Diesel Engine Model | YUCHAI / YC6J200-52 Cummins / ISGe5-400 / ISGe5-430 |

| Inside Diameter of Delivering Pipe | Ф125 |

| Folded Form | 4Z, 5RZ, 6RZ, 7R |

A reasonable concrete pump rate can ensure the uniform flow of concrete in the pipeline, avoiding the separation of concrete due to friction and turbulence, thus ensuring the uniformity and strength of concrete. At the same time, the appropriate pumping rate can also improve the construction cost.

Factors Affecting Concrete Pump Rates

- Concrete Fluidity

The pumping speed of concrete with good fluidity is relatively fast, and the reverse is slow.

- Length and Diameter of The Pipe

The longer and smaller the diameter of the pipe, the slower the pumping speed.

The longer and smaller the diameter of the pipe, the slower the pumping speed.

- Pumping Height

The higher the pumping height, the slower the pumping speed.

- Concrete Mix Ratio

Unreasonable mix ratio will lead to poor concrete flow and affect the pumping speed.

- Pipe Friction

The greater the friction on the inner wall of the pipe, the slower the pumping speed.

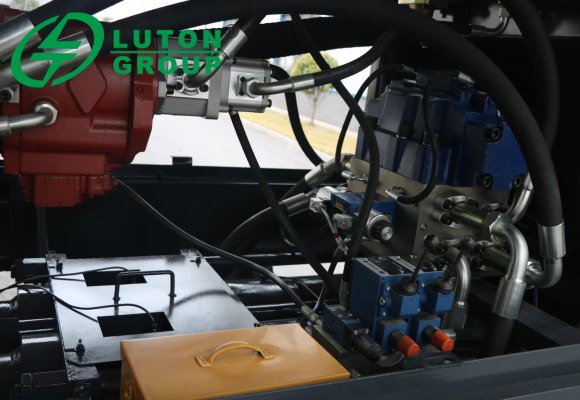

- Equipment Condition

The working state of the concrete pump, the performance of the hydraulic system, etc., will also affect the pumping rate.

- Drive Mode

Electric concrete pumps and internal combustion (such as diesel) concrete pumps may differ in pumping rates. Internal combustion concrete pumps have advantages in field work and in situations where it is difficult to rely on the power grid.

- Design Features

Such as the closed or open oil circuit of the pumping system, the hydraulic stepless speed regulation and the function of adjusting the concrete conveying capacity will affect the pumping speed and stability.

- Working Conditions

The actual pumping rate will also be affected by the specific working conditions of the construction site, such as the concrete mix ratio, the length and diameter of the conveying pipeline, and the pumping height.

How To Adjust The Concrete Pump Rates

- Set Initial Rate Reasonably

Low speed pumping should be adopted when pumping for the first time, and gradually increase the pumping speed after the pumping phenomenon is normal.

- Adjust According To Construction Conditions

set and adjust the pumping rate reasonably according to the flow of concrete, pipe length and diameter, pumping pressure and pumping height and other factors.

- Monitor Concrete State

Always pay attention to the amount of paint in the hopper, avoid too little paint resulting in suction air causing tube blocking, and avoid too much paint affecting the cleaning of coarse aggregate.

- Regular Maintenance

Regular inspection and maintenance of concrete pumps, including hydraulic systems, pipelines, etc., to ensure that the equipment is in good condition to reduce the pumping speed caused by equipment failure.

- Using Mechanical Regulation

By adjusting the size of the throttle opening of the pump car or changing the engine speed to control the pumping displacement, so as to adjust the pumping rate. However, attention should be paid to the adjustment accuracy and ease of operation.

To sum up, the pumping rate of concrete is an important parameter that cannot be ignored in concrete construction. By setting and adjusting the pumping rate reasonably, the construction quality and efficiency can be ensured, and the overall quality of the project can be improved.

Hot Models Of LUTON Concrete Pumps

Mini Concrete Pump

High-Pressure Concrete Pump

Concrete Trailer Pump

Concrete Mixer Pump

Concrete Boom Pump