Concrete pump types are the a basic information that people to know when buying a concrete pump for construction projects. Different types of concrete pumps are specialized in different projects and working environments. Selection of suitable concrete pump according to the actual needs of the project will provide important equipment guarantee for the smooth progress of the project.

Variety of Concrete Solution For All Sorts of Construction Projects:

Concrete Trailer Pump

Concrete Mixer Pump

Truck-mounted Concrete Pump

Concrete Boom Pump

Which concrete pump is the your ideal one?

Main Types of Concrete Pump

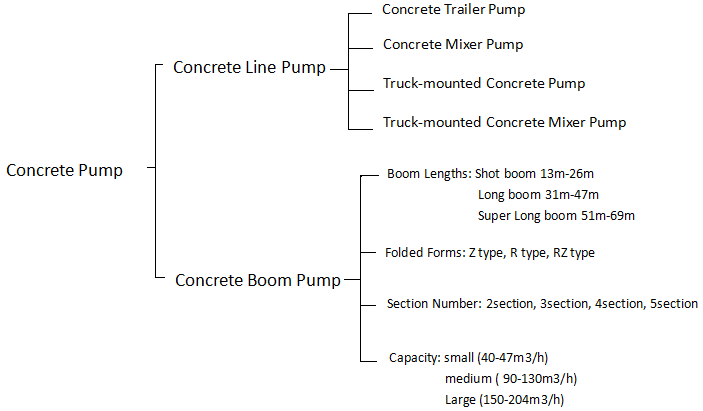

Generally speaking, there are two main types of concrete pump, one is concrete line pump, the other is concrete boom pump. The difference between both is from the concrete delivering methods. The former is pipelines method, while the boom method.

Among them, there are several types as following: concrete trailer pump, concrete mixer pump, truck-mounted concrete pump, truck-mounted concrete mixer pump and so on.

To the boom pump, there are also some types according to the boom folded forms: R type, Z type, RZ type, etc.

In addition, according to the different types of power sources of concrete pumps, there are also classifications of diesel concrete pumps and electric concrete pumps.

What is each type of concrete pump like? What are their characteristics and advantages? And How about their applications in construction industry? Now, let’s take a further understand of concrete pump types.

Concrete Trailer Pump

Concrete trailer pump, also known as concrete conveying pump, towing pump, etc., is a kind of concrete line pump. It is one of the most widely used concrete pumping equipment in the construction field. Composed of pumps and delivery pipes, this kind of concrete pump is usually designed on a trailer chassis with wheels. So, it can be easily towed by a trailer.

- Easy to move

- Small body size

- Compact structure

- Strong Pumping Capacity

- Flexible Suitability To Environment

Concrete trailer pump is suitable for almost all concrete pumping environment. It is widely used in bridges, highways, airports, dam, tunnels, underground projects, high-rise building construction, residential construction, water conservancy and power facilities constructions. Even in the world-famous 828m Burj Dubai project, you can see the group of small-body but large-power concrete trailer pumps.

The pumping capacity of commonly used concrete towing pump ranged from 25m3/h to 120m3/h. Users can select suitable models according to the actual engineering requirement.

Hot Models of LUTON Concrete Trailer Pump

| Items | HBT30-6-52R |

| Max.theo.concrete output (L/H) | 30m3/h |

| Max.concrete pumping pressure(L/H) | 6MPa |

| Distribution valve type | s |

| Concrete cylinder diameter×stroke | Ф200×500mm |

| Outlet diameter | Ф180mm |

| Diesel engine model | Yuchai |

| Electrical engineering power | 52KW |

| The biggest transportation(vertically/Level) | 100/300m |

| Items | HBT40-10-82R |

| Max.theo.concrete output (L/H) | 40m3/h |

| Max.concrete pumping pressure(L/H) | 10MPa |

| Distribution valve type | s |

| Concrete cylinder diameter×stroke | Φ180/1300mm |

| Outlet diameter | Ф150mm |

| Diesel engine model | Weichai |

| Engine power | 82KW |

| The biggest transportation(vertically/Level) | 120/500m |

Hot Models of Small Concrete Pump

According to different aggregate particle sizes and application scenarios, concrete trailer pump can also be categorized into: small concrete pump, mortar pump and mortar spraying pump.

Small concrete pump, more compact, suitable for secondary construction inside the building. At present, LUTON small concrete pumps with the following models, play roles in different application projects and have had received unanimous praise from users.

Mortar pump for conveying aggregate particle size less than 20mm.

Mortar spraying pump, is used for pumping mortar with small aggregate particle size (less than 20mm) , for the need of spraying mortar concrete on the construction surface, mostly used for interior decoration, wall maintenance, mountain protection, dam engineering, etc.

| Model | HBT25C-08-42R |

| Max. Theo. concrete output(L./H.) | 25-13 m3/h |

| Theoretical conveying height | 30m |

| Theoretical horizontal pumping distance | 60-80m |

| Concrete cylinder (diameter×stroke) | Ф140mm×550mm |

| Aggregate particle size range | 10-30 |

| Dimensions (mm*mm*mm) | 3400*1100*1500 |

| Power | 15 kw |

| Maximum Aggregate | < 20 mm |

| Vertical Conveying Height | 20 m |

| Horizontal Conveying Distance | 60 m |

| Transport Capacity | 6-8 m3/h |

| Pipe Diameter | 80 mm |

| Cylinder (Diameter*Stroke) | 120 mm*360 mm |

| Model | PBM20 |

| Theoretical concrete output | 1.5/1.8 m3/h |

| Theoretical concrete pumping pressure | 1.5 MPa |

| Max. vertical conveying height | 12-15 |

| Max.horizontal transmission distance | 50m |

| Max.Aggregate particles | 6mm |

| Overall dimensions(L*H*W) (mm*mm*mm) | 1700×870×950 |

Concrete Mixing Pump

Concrete mixing pump is a type of multifunctional concrete equipment which integrates mixing and pumping function. In addition to the trailer pump, a mixing system is also added in. This kind of pump is especially suitable for the projects in remote areas without commercial mixing plant near, needing to mix concrete onsite. A concrete mixing pump and conveying pipeline can easily solve the concrete problem. Because the transmission mode of mixing pump is also pipeline method, concrete mixing pump is still a kind of concrete pipeline pump.

The hot models of LUTON concrete mixer pump are the following.

| Items | JBS40-10-82R |

| Max.theo.concrete output | 40m3/h |

| Mixer rated discharge capacity | 0.45m3 |

| Max.concrete pumping pressure | 10MPa |

| Distribution valve type | S |

| Diesel engine model | 82KW Weichai Deutz WP4G110E220 |

| Max. Theoretical Conveying Distance (Vertical/Horizontal) | 120m/500m |

| Items | JBS40B-JS750 |

| Main oil pump | Kawasaki, Korea |

| Main oil pump discharge | 112(ml/r) |

| Main Engine | 45 kw |

| Power of agitating motor | 30kw |

| Mixer productivity | 35 |

| Lubricating system | Automatic |

| Piping (m) | 100 m Φ125 |

| Items | JW40D-1000R |

| Max. theo. output | 50m3/h |

| Mixer Feeding Capacity | 1600L |

| Mixer Discharge Capacity | 1000L |

| Max.concrete pumping pressure | 129 WEICHAI DEUTZ or 132KW CUMMINS |

| Pumping system pressure | 28Mpa |

Truck-mounted Concrete Pump

Truck-mounted concrete pump is also a type of concrete pipeline pump, which also needs to set up conveying pipe in advance onsite. In order to facilitate long-distance transportation and use, people installed the concrete delivery pump on truck chassis. After development and improvement of concrete pump manufacturing, now the truck mounted concrete pump is more and more mature and perfect.

With the support of the truck chassis, this kind of pumping equipment can reach more remote areas, and directly carry out concrete conveying operations on truck, without the need of equipment disassembly. For the construction party, it saves a lot of time, with the use of convenient and flexible.

Truck mounted concrete pump includes concrete conveying pump truck and concrete mixing pump truck. LUOTN GROUP best-selling pump trucks are the following.

| Model | HBCS100 |

| Maximum Theoretical Concrete Output | 100 m3/h |

| Aggregate Size | Pebble≤50mm Gravel≤40mm |

| Power | 186kw |

| Conveying Cylinder Diameter | Ф230mm×1800mm |

| Hydraulic System Pressure | 32Mpa |

| Type Of Distribution Valve | S Valve |

| Maximum Theoretical Conveying Distance | 1000m/250m |

| Model | HBCJ50-9-45ES |

| Concrete output | 50 m3/h |

| Pump Pressure | 9 Mpa |

| Main Motor Power | 45 kw |

| Mixer Model | JS500 |

| Main Oil Pump Cylinder × Stroke | Φ100mm×1000mm |

| Conveying Cylinder × Stroke | Φ200mm×1000mm |

| Max. aggregate diameter | Gravel 40mm / Pebble 50mm |

Concrete Boom Pump

Concrete boom pump is one of the most special concrete pumping equipment. It is designed on a special truck chassis. In addition to pumping system, there is also a set of foldable boom specially for transporting concrete. When it is not working, the boom is folded on the frame. When it is working, the boom is expanded through the intelligent control system to adjust the angel of the boom, and finally directly reach to the designed construction area.

Before work, it is necessary to choose a reliable parking point for the boom pump truck and fix the support legs steadily.

Advantages of Concrete Boom Pump

- The arm length of the boom pump truck ranges from more than 10m to more than 100m. These pump truck with different-length-arm can provide raw material conveying works for concrete projects of different scales.

- Intelligent arms are erected in the sky, do not rely on any ground environment, even in deep ditch, river, tall buildings and other construction environment can easily pump concrete to the desired place.

- Concrete boom pump is efficient. And the fully closed pumping method doesn’t cause too much air pollution. It is an indispensable concrete pumping equipment for the efficient modern construction industry.

According to the different arm length, LUTON arm pump can be divided into 13m-28m short arm, 31-47 m long arm, 51-69 m super long arm, etc.

| Model | LTB40R-21 |

| Max.theo.concrete output | 50m3/h |

| Max.concrete pumping pressure | 10MPa |

| Vertical height of boom | 22M |

| Leg open width | 5.5M |

| Diesel engine model | WP4G110E220 Weichai |

| Engine power | 82KW |

| Model | LT5216THB21 |

| Generator Engine | Straight 6 Cylinder 145kw/1800r/min |

| Boom Form | 4 Section Hydraulic Fold |

| Platform Rotation | 360° |

| Boom Horizontal Length/ Depth | 19.73 m /23 m |

| Hydraulic System Pressure | 20 MPa |

| Conveying Pipe Diameter | Φ125 mm |

In Future

With the continuous development of modern building technology, concrete pumping technology has also made great progress. It is believed that after the unremitting efforts of generations of LUTON people, concrete pump products of LUTON GROUP will get more comprehensive and long farther development in the automation, control accuracy, mixing performance, remote monitoring, environmental protection measures, product life and other aspects.