Concrete Pump Trailer For Sale

Find the perfect concrete trailer pump for sale to pour concrete to every hard-to-reach place and finish your project as scheduled!

Choose Luton’s concrete trailer pump to minimize the cost and maximize the efficiency and return.

7, 200 pumps

7,000+ concrete trailer pumps are sold

100+ countries

Exporting to over 100 countries overseas

Reach out to us to get a free quote!

Popular Concrete Trailer Pumps For Sale

Hot selling models

Luton’s trailer-mounted concrete pump is the best seller among all concrete pumps for being compact, convenient, and economical.

Our concrete trailer pump for sale includes mini and small sizes as well and also supports customized service. Luton’s line concrete pump models are from HBTS30 – HBTS90 with the capacity from 30m3h~100m3/h such as HBTSB40, HBTSB50, HBTSB60, HBT80, HBT90C.

Besides, we also offer two options: Diesel concrete trailer pump, electric concrete trailer pump

HBTS 30

Our Quotation: $ 17, 000 – $ 30, 000

Market price: $ 22, 000 – $ 50, 000

| Model | HBTS 30 |

| Max. Output capacity (m³/h) | 30 |

| Max.Concrete Pumping Pressure (Mpa) | 10 |

| Max. Horizontal Conveying Distance (m) | 450 |

| Distribution Valve Type | S Valve |

HBTS 40

Our Quotation: $ 17, 500 – $ 30, 000

Market price: $ 23, 000 – $ 50, 000

| Model | HBTS 40 |

| Max. Output capacity (m³/h) | 40 |

| Max.Concrete Pumping Pressure (Mpa) | 10 |

| Max. Vertical Conveying Distance (m) | 800 |

| Distribution Valve Type | S Valve |

HBTS 60

Our Quotation: $ 18, 000 – $ 30, 000

Market price: $ 25, 000 – $ 50, 000

| Model | HBTS 60 |

| Max. Output capacity (m³/h) | 60 |

| Max.Concrete Pumping Pressure (Mpa) | 13 |

| Max. Vertical Conveying Distance (m) | 1, 000 |

| Distribution Valve Type | S Valve |

HBTS 80

Our Quotation: $ 20, 000 – $ 50, 000

Market price: $ 30, 000 – $ 60, 000

| Model | HBTS 80 |

| Max. Output capacity (m³/h) | 88 |

| Max.Concrete Pumping Pressure (Mpa) | 16 |

| Max. Vertical Conveying Distance (m) | 1, 200 |

| Distribution Valve Type | S Valve |

Exported Cases of LUTON Concrete Pump Trailer

Trust Luton, Your Loyal Partner

100+ Exporting Countries

Including Myanmar, Vietnam, Laos, Thailand, Cambodia, Malaysia, the Philippines, Singapore, Indonesia…

80+ Famous Partners

Such as Hongtai Group, Zhongming Zhuyou, China Railway, China State Construction…

20+ Honors and Patents

ISO 9001:2000 quality management system, CE, BV certificates, and owns 6 national patents, and other advanced honors.

1, 8000+ Pumps Sold

Over 1, 8000 static concrete trailer pumps have been sold out across the world and receive positive feedback

Our Main Partners Display

Main Specifications Of Luton Concrete Pump For Sale

We have more options for your projects, offering more possibilities. More parameters of small diesel concrete pump and electric concrete pump areas are listed below:

Diesel Concrete Pump

| Model | HBTS40-10-82R | HBTS60-13-129R |

| Max. Theoretical Throughput (m3/h) | 40/26 | 67/45 |

| Max. Pumping Pressure (MPa) | 10/7.6 | 13/7 |

| Max. Theoretical Vertical/Horizontal Conveying Distance (m) | 120/500 | 180/800 |

| Rotate speed (kW) | 2100 | 2200 |

| Mixing system pressure(MPa) | 6-8 | 6-8 |

| Concrete cylinder diameter×stroke | Φ180×1200 | Φ200×1650 |

Electric Concrete Pump

| Model | HBTS30 | HBTS40 | HBTS50 | HBTS80 |

| Max. Theoretical Throughput (m3/h) | 30 | 40 | 50 | 80 |

| Max. Pumping Pressure (MPa) | 10 | 10 | 10 | 16 |

| Power of Main Electric Motor (kw) | 100 | 160 | 160 | 180 |

| Max. Aggregate Diameter (mm) | 30 | 40 | 50 | 30 |

| Hydraulic Oil Tank Capacity (L) | 250 | 400 | 500 | 800 |

| Power of Main Electric Motor (kw) | 45 | 45 | 55 | 110 |

The main specification is for your reference. Our concrete trailer can be customized according to your needs.

Only Provide Top-class Trailer Pumps

Competitiveness of our concrete trailer pump

Anti-wear Tested S tube

The S tube valve is cast into shape with austenitic manganese steel and has the dual advantages of anti-high pressure and anti-wearing.

Full Oil Tank

The fuel filler is located on the top of the fuel tank, and it is full when the concrete trailer pump is newly made in the factory.

Water Cooling System

Due to the hydraulic system, water cooling is generally available for those HBTS 20 – 40 concrete pumps to increase the heat dissipation effect. Many manufacturers do not support water cooling functions, but Luton adopts it.

Excellent Accumulator

The certain internal pressure plays a buffering role in the process of high-pressure oil release, reducing the impact on the hydraulic components and increasing the service life of the hydraulic components.

See Sincerity And Strength In Each Part

Please follow the operating rules to ensure safety and prolong trailer-mounted concrete pump service life.

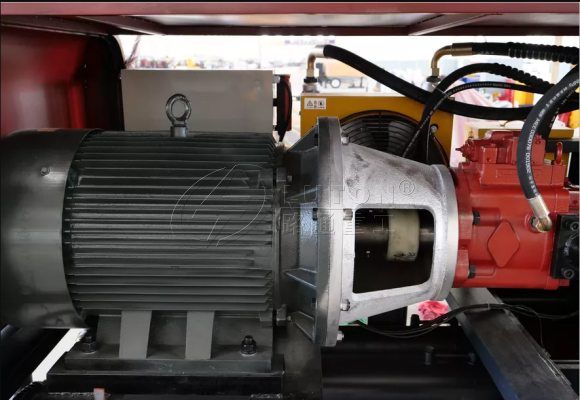

Hydraulic System

The quality of the hydraulic system directly affects the working performance and efficiency of pump trucks, especially large flow pump trucks, which generally use open circuits and constant power control.

Our hydraulic system adopts hydraulic buffering technology and famous Germany-made components and Itay Manuli hydraulic hose, standing out for high reliability, easy maintenance, and good heat dissipation conditions.

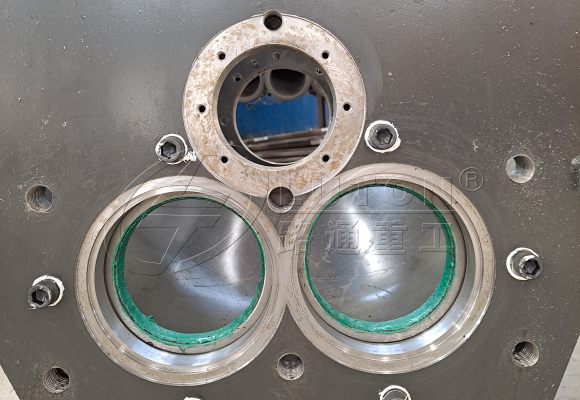

Pumping System

The pumping system allows the concrete to be conveyed to further and higher places. The quality and power of pumping has an impact on the distance of concrete transportation.

Our high-pressure pump has the reverse pump function, it aims to eliminate the pipe blockage in time, and can be stopped for a short time. And the concrete can be pumped up to 300 meters vertically and 1, 200 horizontally.

Electric Control System

The electrical control system is mainly used to control the start and pause of the hydraulic pump, engine speed, etc. In addition to the electrical control system, a manual control system is also installed, which is also a part of the control system.

Our electric control is simple and safe to operate, ensuring precise control and preventing errors. But remember, please follow strictly the instructions.

Lubrication System

The lubrication system adopts a progressive distributor which supplies every lubrication point with oil in turn, and the oiling time can be set to save oil.

Safety Note On Concrete Trailer Pump Operation

(1) The axle of the towing pump is a low-speed axle, which can only be towed on the spot for a short time and cannot be driven on the road. It is must be mounted on a truck for long-distance towing.

(2) The outriggers should be set up to prevent the tires from contacting the ground, otherwise, they will be damaged due to the machine vibration.

(3) When the pumping system working, the concrete in the hopper should be kept above the axis of the mixing shaft. The feed flow rate shall be controlled, the oversized aggregate and foreign matter shall be cleaned in time.

(4) When the concrete in the hopper is segregated, stop the pump from working and mix concrete evenly. When the aggregate separation is serious and the mortar in the hopper is obviously insufficient, part of the aggregate should be removed, and mortar should be added to re-mix

Get A Free Quote

Mobile:

0086-173-2016-6678

Whatsapp:

0086-173-2016-6678

Email:

sales@ltconcretepump.com