In the world of construction, space is a luxury that many urban, renovation, and specialized projects simply cannot afford. This is where the compact concrete pump emerges as a revolutionary force. But what exactly is it? How to choose your ideal compact concrete pump? Is it easy to operate and maintain? Welcome to LUTON compact concrete pump world!

| Output Capacity | 10~60 m³/h |

| Max. Pumping Pressure | 10 MPa |

| Delivery Distance | 150m vertical 500-800m horizontal |

| Engine Power | 16~90 kW diesel/electric |

| Max. Aggregate Diameter | 20~30mm/40mm |

What Is A Compact Concrete Pump

Redefining efficiency in tight spaces, a compact concrete pump is a specialized, highly maneuverable machine designed to transport liquid concrete efficiently in confined or difficult-to-access job sites. Unlike its larger, truck-mounted cousins, a small compact concrete pump prioritizes a minimal footprint, exceptional portability, and rapid setup without compromising core pumping performance. It is the definitive answer when traditional methods like crane-and-bucket or full-sized pump trucks are impractical, too expensive, or physically impossible to deploy.

Think of narrow alleyways in city centers, low-ceiling basements, complex indoor renovation projects or sensitive historical structures. The compact concrete pump excels here, transforming logistical nightmares into streamlined, efficient workflows. Its core mission is to deliver professional-grade concrete placement precisely where it’s needed most, overcoming the stringent limitations of space and accessibility.

Application Cases Of LUTON Compact Concrete Pump

A compact concrete pump is not just a piece of equipment. It is a strategic enabler for projects that defy conventional construction methods. Its compact and portable value is realized in environments where space is primary constraint. Here are the key application scenarios where it becomes an indispensable asset.

LT-10A Mini Concrete Pump in Maldives

JBS40 Compact Mixer Pump in Kenya

HBTS40 Compact Trailer Pump in Indonesia

HBTS30 Compact Trailer Pump in Panama

Why Choose A Compact Concrete Pump Rather Than A Traditional Pump

Why choose a compact concrete pump over other methods? The advantages are clear and impactful:

Unmatched Accessibility

With widths often under 1.8m and significantly reduced setup space, these pumps can navigate standard doorways, narrow passages, and steep inclines that are completely off-limits to larger equipment.

Rapid Deployment & Mobility

Designed for easy transport on a light-duty truck or trailer, portable concrete pump can be on-site, set up, and pumping concrete in a fraction of the time required for a large boom pump, saving crucial project hours.

Cost-effectiveness

It eliminates the need for expensive secondary placement methods (like conveyors or manual labor) in tight spaces. The reduction in labor, time, and equipment rental costs often delivers a superior return on investment for applicable projects.

Precision & Reduced Wasted

Operators have excellent control over the placement of concrete, allowing for precise pours in complex formworks. This minimizes spillage and waste, leading to cleaner sites and materials savings.

Versatility in Application

From pouring footings and slabs in residential backyards to performing structural repairs inside buildings or constructing garden walls, the mini concrete pump is a multi-faced tool for contractors across various sectors.

In essence, the compact concrete pump is not merely a smaller alternative. It is a strategically superior solution for a significant segment of modern construction challenges. It empowers contractors to take on projects the might have previously declined or found unprofitable, turning spatial constrains into a manageable variable rather than a project-stopping obstacle.

Compact Concrete Pump Specifications

Navigating the technical specifications is key to matching the right machine to the project’s demands. Below, we break down the critical specs and provide a clear model comparison to guide your selection.

Core Technical Specifications Explained

Understanding these parameters will help evaluating performance and compatibility:

Theoretical Concrete Output

Ranges from 10 to 60 m³/h in compact models. This indicates the maximum volume the pump can deliver under ideal conditions. For most confined-space projects like basements or renovations, a range of 10-60 m³/h provides an optimal balance of speed and control.

Maximum Pressure

This is the engine’s ‘muscle’, determining the pumping distance. Higher pressure allows for:

- Greater Vertical Reach: up to 150m or more with high-pressure models.

- Longer Horizontal Distance: Capable of 500-800m of pipeline

Pro Tip: For high-rise construction (even via interior shafts) or long, horizontal runs, prioritize pressure over raw output volume.

Engine Power & Type

- Diesel Engines

Typically 10-90 kW, offering robust, self-contained power for remote or outdoor sites.

- Electric Motors

Provide quiet, zero-local-emission operation, essential for indoor projects, hospitals, or schools. Operating costs are significantly lower.

Aggregate Size

The maximum diameter of stone the pump can handle, usually up to 40mm. Ensure this matches your concrete mix design.

Dimensions & Weight

The essence of compact. Key metrics include:

- Transport Width: as narrow as 0.9~1.85m for ultimate access.

- Height: Low-profile designs under 1.2~1.8m for doorways and low ceilings.

- Weight: 780~4500 kg

Model Comparison of LUTON Compact Concrete Pump

The table below compares typical configurations of our compact concrete pump series to illustrate how specifications align with different project profiles.

| Feature / Model | LT-10A/HBTS10-04-16R | HBTS40-10-66R HBT40-10-45 | HBTS60-13-90R |

| Theoretical Output | 8-10 m³/h | 40 m³/h | 60 m³/h |

| Max. Pressure | 4 MPa | 10 MPa | 12 MPa |

| Engine Type | diesel 16kW/18.7kW | diesel 66kW or electric 45kW | diesel 90kW |

| Aggregate Size | 30mm | 30mm or 40mm | 40mm |

| Key Advantage | cost-effectiveness easy transport | perfect balance of power & size | max. power in a compact frame |

| Ideal For | · samll residential jobs · interior walls · grouting | · urban infill · multi-story buildings · standard commercial work | · large-scale confined sites · high-rise cores · tunneling |

Beyond the Specs – Smart Features That Matter

Modern compact concrete pumps integrate intelligent features that enhance productivity and reduce operator burden:

Advanced PLC Control System

Automatically adjusts output and pressure for optimal eficiency and protects the system from overloads.

Wireless Remote Control

Allows for single-operator, line-of-sight control, improving safety and placement accuracy.

Diagnostic Displays

Real-time monitoring of engine vitals, hydraulic temperature, and wear parts helps prevent unexpected downtime.

Automated Lubrication

Ensures the wear-prone S-tube valve system is consistency maintained, extending component life.

Choosing the right pump isn’t just about the highest numbers. It’s about finding the machine whose specifications – output, pressure, size, and features – neatly solve the specific equation of the project’s access, reach, and output requirements. Use this comparison as a starting point for a detailed conversation with our technical team.

How To Choose The Right Compact Concrete Pump

Select the ideal compact concrete pump is a strategic decision that directly impacts your project’s efficiency, cost, and success. With various models and specifications available, making an informed choice requires a clear understanding of your needs and the machine’s capabilities. This guide walks you through the essential steps and considerations.

Step 1 Assess Your Project Requirements

Begin by defining the specific challenges and demands of the job site:

Space & Access Constrains

Measure the narrowest width, lowest clearance, and ground conditions (e.g., soft soil, finished floors) the pump must traverse.

Concrete Placement Needs

Determine the maximum vertical reach and horizontal pumping distance required from the pump’s setup location to the farthest pour point.

Output Demand

Estimate the required concrete output (m³/h) based on your crew size, pour size, and project timeline. Avoid over-specifying for cost-efficiency.

Material Specifications

Know the mix design – especially the maximum aggregate size – as pumps have limits on what they can handle.

Step 2 Understand Critical Performance Specifications

When comparing models, focus on these core technical parameters:

Output Capacity

Ranging from 10 to 60 m³/h for most small compact concrete pumps. Higher output speeds up large slab pours, while a moderate, steady output is perfect for precise, continuous work like shotcreting or pressure grouting.

Pressure & Reach

The pump’s hydraulic pressure determines its ability to push concrete over distance and height. Ensure the combined horizontal and vertical reach meets your project’s maximum requirement with a safe margin.

Engine Power & Type

Diesel engines offer robust power and fuel availability for remote sites. Electric motors provide zero emissions, lower noise, and reduced operating costs, ideal for indoor or environmentally sensitive projects. Hybrid options are now emerging.

Dimensions & Maneuverability

This is the compact advantage. Check the transport width, weight, and whether it features rubber tracks or tires suitable for the ground conditions. The best portable compact concrete pump balances power with actual site accessibility.

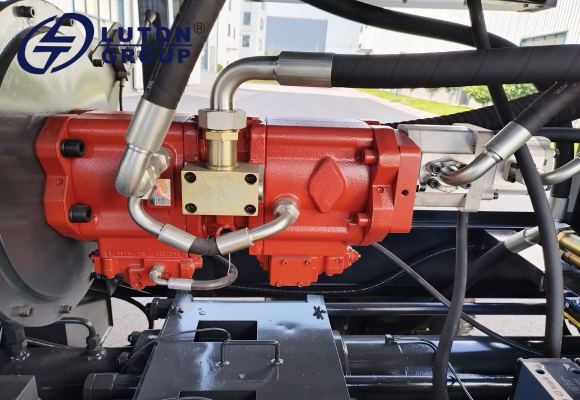

Key Component & Technology

- Valve System

The S-tube valve is the industry standard for reliability in handling standard mixes. A rock valve might be specified for more abrasive or harsh mix designs.

- Control System

Modern PLC-based systems with wireless remote controls enhance safety, precision, and ease of operation.

- Safe & Monitoring

Look for overload protection, emergency stop systems, and real-time monitoring of critical functions like hydraulic temperature and pressure.

Step 3 Make the Final Decision – Key Question to Ask

Use this checklist to evaluate the options:

- Rent or Buy ?

For one-off projects or testing a new market, compact concrete pump rental is flexible. For frequent use, purchasing offers long-term value and asset control.

- What is the True Total Cost of Ownership ?

Look beyond the compact concrete pump price. Consider fuel efficiency, standard warranty, expected maintenance costs, and the availability/cost of spare parts like wear plates and cylinders.

- Does the manufacturer Offer Support ?

A reliable supplier provides not just a machine, but comprehensive after-sales service, operator training, and readily available technical support – critical for minimizing downtime.

- Can I See It Work ?

Request real-world case studies from similar projects or, better yet, a live demonstration at your site or their facility.

By methodically working through these steps, you will equip yourself to select a compact concrete pump that isn’t just a piece of equipment, but a tailored productivity partner engineered for the specific demands of the confined-space projects.

Renting vs. Owning A New Compact Concrete Pump

For forward-thinking contractors, owning an equipment isn’t an expense – it’s a cornerstone of growth, control, and profitability. While renting offers a short-term fix, purchasing a compact concrete pump is a strategic investment that pays continuous dividends.

| Aspect | The short-term Rental | The Long-term Ownership |

| Cost Control | Variable, recurring expense. Rates can increase. Availability isn’t guaranteed. | Fixed asset cost. Predictable long-term investment with no recurring rental fees. |

| Project Readiness | Delays waiting for delivery. Risk of unsuitable or poorly maintained equipment arriving. | Immediate, guaranteed availability. Your project schedule is in your hands. |

| Equipment Condition | Unknown maintenance history. Potential downtime due to wear from previous users. | Full maintenance control. You ensure peak performance and know its history intimately. |

| Brand & Professionalism | Generic rental equipment at your site. | Your brand on a professional asset enhances credibility and marketing appeal. |

| Total Cost of Operation | Higher over time. Repeated rentals for multiple projects drain profits. | Lower lifetime cost. After the initial payback period, your cost per project plummets |

Easy Maintenance & Operation of Compact Concrete Pump

A great machine stays great with proper care. Owning a compact concrete pump is straightforward. Here’s a simple guide to keep the compact concrete pump running smoothly for years, maximizing the investment.

Key to Long Life – Daily Check

Before starting the pump each day, quickly check these points. This quick routine prevents most major issues.

- Fluids: Engine oil, hydraulic oil, and coolant levels.

- Grease: Ensure the automatic grease system is full and working.

- Pipe & Hoses: Look for leaks, damage, or severe wear.

- Controls: Test the emergency stop and remote control functions.

Maintenance Plan – Less Downtime, More Uptime

Follow this easy schedule to avoid accidents:

- Every 50 hours: Grease all fittings, check and clean filters.

- Every 250 hours: Change engine oil and filters. Inspect wear parts like pistons and sealing rings.

- Every 1000 hours: Major service. Change hydraulic oil and filters. Have a technician perform a full system check.

Pro Tips: Use only high-quality fuels, oils, and genuine spare parts. This protects the pump’s engine and hydraulics, saving money on repairs.

Troubleshooting – Quick Fixes For Common Issues

Low Pressure/Output?

Check for a worn-out wear plate or S-tube seals – the most common wear parts.

Concrete Too Thick?

Don’t force the pump. Use a well-mixed, pumpable concrete to avoid blockages and pressure.

Small Leaks

Address them immediately. A small leak today can become a big failure tomorrow.

We Make Maintenance Easy

You’re not alone. LUTON GROUP supports your operation with:

- Clear manuals & Training: We provide easy-to-follow guides and training for your team.

- Ready-to-ship Parts: We keep a full stock of common wear parts for fast delivery.

- Expert Support: Our technicians are just a call away to help with any question.

A well-maintained pump is a reliable profit machine. Simple care means less downtime, lower costs, and longer life for the equipment.

Want a simple maintenance plan for your model?

Contact us for a free, customized maintenance schedule and a list of recommended spare parts for your specific pump. Let’s keep your business running smoothly.

FAQs On Compact & Mini Concrete Pumps

What exactly is a “mini” or compact concrete pump, and how is it different from a large boom pump?

A compact concrete pump is a small, highly mobile machine designed for pumping concrete in tight, hard-to-reach places. The main difference is size and purpose. Large boom pumps are for massive, open-site pours with high volume and reach. Compact Pumps sacrifice sheer volume for extreme accessibility, fitting through gates and into basements where larger equipment simply cannot go.

What are the most common jobs for a compact concrete pump?

They are the ideal solution for: pouring basement foundations, backyard slabs, swimming pools, sidewalks in narrow alleys, interior floor/structural upgrades, tunnel lining, retaining walls, and landscaping projects. Anywhere space is limited.

Is a compact concrete pump powerful enough for my project?

Absolutely. Modern small compact pumps can deliver concrete over 150 meters vertically and 500+ meters horizontally. They handle standard concrete mixes with aggregate up to 40mm, making them suitable for the vast majority of residential and light commercial projects.

How many people are needed to operate it?

Typically, just one trained operator using a wireless remote control. A second person may help with initial pipeline setup and general site coordination, but the pump itself is a one-person operation, saving on labor costs.

Do you offer electric models, and why would I choose one?

Yes, we offer electric compact concrete pumps. Choose one for indoor projects (zero emissions), work in noise-sensitive areas (much quieter), or to significantly reduce long-term energy costs compared to diesel fuel.

What support do you offer after I purchase a pump?

Your investment is backed by our full support: comprehensive operator training, detailed maintenance plans, a global parts inventory for fast shipping, and access to technical experts for troubleshooting. We ensure your pump delivers maximum uptime and productivity.

Have More Questions? Get the Right Answers.

Every project is unique. Speak directly with out application experts for personalized advice and a solution tailored to your specific job site challenges.

Hot Models of LUTON Concrete Pumps

Mini Concrete Pump

High-Pressure Concrete Pump

Concrete Trailer Pump

Concrete Mixer Pump

Concrete Boom Pump