Mini Concrete Pump

The mini concrete pump featured as lightweight, compact and simple, is perfect for small scale construction projects on narrow sites.

LUTON small and mini concrete pump machine meets your expectations of low price, premium quality, high duty, simple operation, and high efficiency!

Compact Design

Cut 40% weight

Affordable Price

Save 35% cost

Reach out to us to get a free quote!

Hot Mini Concrete Pump Machine

Popular Mini Concrete Pump For Sale

LUTON provides several mini concrete pump types: mini concrete trailer pump, mini mixer pump, mini secondary constructral pump and so on. These types of pumping machines meet most of your small and middle construction demands.

Our small and mini concrete pumps for sale include but are not limited to:

Mini Concrete Trailer Pump: HBCS 30

| Model | HBTS 30 |

| Max. Output Capacity | 30 m³/h |

| Max.Concrete Pumping Pressure | 10 Mpa |

| Max. Vertical Conveying Distance | 140 m |

| Distribution Valve Type | S Valve |

Mini Concrete Mixer Pump: JBS 30C

| Model | JBS 30C |

| Max. Output capacity | 30 m³/h |

| Max.Concrete Pumping Pressure | 10 Mpa |

| Max. Vertical Conveying Distance | 220 m |

| Distribution Valve Type | S Valve |

Mini Secondary Constructral Pump: LT-8A

| Power | 15 kw |

| Maximum Aggregate | < 20 mm |

| Vertical Conveying Height | 30 m |

| Horizontal Conveying Distance | 60 m |

| Transport Capacity | 6-8 m3/h |

| Pipe Diameter | 80 mm |

| Cylinder Diameter*Stroke | 120 mm*360 mm |

Choose Luton, Your Wise Choice

100+ Exporting Countries

80+ Famous Partners

20+ Honors and Patents

1,8000+ Concrete Pumps Sold

30% Faster Delivery

24 Hours After-sale Service

Our Partners

Cooperating with many famous domestic and abroad enterprises, Luton has proved its strength and competitiveness in producing concrete pumps.

Interested in LUTON’s flexible and portable mini concrete pump? Welcome to Luton to get the most worthy equipment and receive higher returns.

LUTON Mini Concrete Pump All Over the World

LUTON mini concrete pump machine is priced reasonable compared to other manufactures like Sany and Aimix. Luton offers you the best piece even you order only one pump.

Our pump has reported to many countries and gained positive customer feedback. Check out the following cases and projects:

Luton small trailer line pump LT-25 sold to America

Luton mini static concrete line pump HBST30 is ready for shipping to Indonesia.

Luton mini concrete mixer with pump JBS40 in Tansania

Luton mini concrete mixer pump sold to Guyana

Mini Concrete Pumps, High Efficiency

Why choose a mini concrete pump?

Owning to the compact design and high concrete convey distance, the mini concrete pump can finish more small projects, therefore it is welcomed in some rural areas or any small worksite where large equipment can not access.

It occupies less work area, saving more places for other material and equipment.

A mini concrete pump can be used in projects that require a small amount of concrete pouring.

It is more flexible to move and can be mounted on a truck.

Mini concrete pumping machines can also pour concrete far and high by pipelines.

Save labor cost because is less expensive compared to large equipment.

A small concrete mixer pump is more productive than a separate mixer truck and trailer pump.

It is also can be used for pressure grouping foundation

The turbocharged engine used in the small concrete pump is energy-efficient, convenient, and fuel-efficient.

The imported mainstream high-flow hydraulic main pump is used to match the kinetic energy of the engine reasonably and work efficiency per unit time.

The enlarged lower frame, internal reinforcement, the load-bearing capacity of the small concrete pump, is suitable for more operations.

Need a large concrete pump? Check out our cement truck with a pump.

LUTON supplies versatile and inexpensive pumps to you and supports customized service! Contact us to get a Luton concrete pump now!

Also Read:Mini Concrete Pump Price

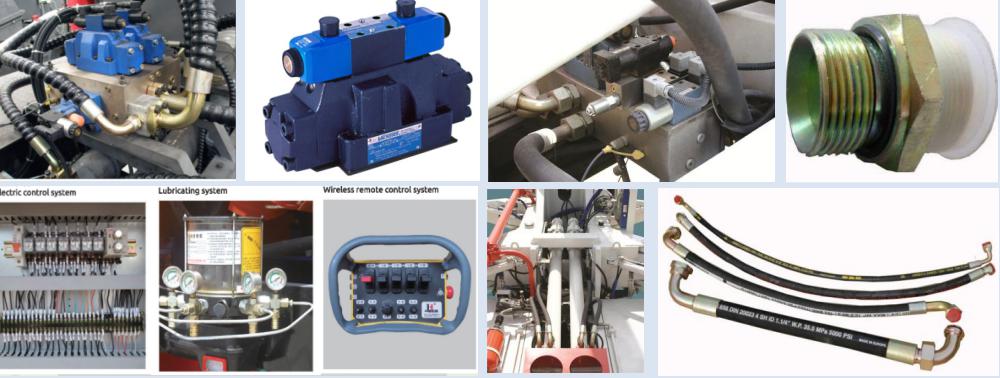

0% Errors in Each Part of LUTON Mini Concrete Pump

Luton put efforts into developing the best components and systems for both mini and large concrete pumps. You can still see our strength and investment in the following components:

Main Oil Pump

Luton’s min oil pump has adopted the HAWE, Rexroth, and Kawasaki brand, ensuring the best quality and durability.

The plunger pump can meet your requirement of pouring volume, which can be adjusted freely.

S Tube

The S Tube is cast into shape with austenitic manganese steel and has the dual advantages of anti-high pressure and anti-wearing.

With a floating wearing ring on the S valve, it achieves self-compensating wearing.

Cooling System

Luton’s concrete pump has both an air cooling and water cooling system to make sure the machine operates smoothing without any errors caused by heat.

It makes the machine more reliable and prolongs the service life.

PLC Control

The control is easy to operate and doesn’t need too complicated training. The wireless remote control enables it to move flexibly and saves labor.

But the operator should be a skilled worker and know very well about to prevent an accident.

Centralized Lubricating

The lubrication system makes sure every lubrication point is filled with oil in turn thanks to its progressive distributor. Besides, the oiling time can be set to save oil.

What other concrete pumping options?

Notes On Applying Mini Concrete Pumping Machines

Before Operating

1. Check the connection points of each pipeline to make they are installed firmly and right.

2. Check the water tank and hopper to see if they are full of water.

3. Check the lubrication oil in the hydraulic oil tank to see whether the oil is insufficient, fill it up.

4. Check the work area to see if there are any obstacles to high voltage lines. If there are, move them away.

During Operating

1. monitor all indicators at any time in case anything goes wrong and adjust it in time.

2. Before the mortar is pumped, the concrete should be poured into the hopper to prevent the concrete cylinder from being emptied (the hopper must be filled with concrete/mortar/water), which may cause pipe blockage.

3. If the pumping is stopped for a long time, the pump must be turned on every 5-15 minutes, reverse the pump for 1-2 strokes, and then push the pump for 1-2 strokes to prevent the concrete from condensing in the pipe.

4. Keep it from raining and any other factors that may damage it.

After Operating

1. Clean the hopper, oil tanks, and pipelines to prevent any cracks and get ready to use next time.

2. Regular maintain the machine. It prolongs the service life and reduces the cost in a long term.

3. Restore it in the right place that prevents fire and water.

More safety of operating concrete pump. Click here.

Reliable, Trusted, Experienced

LUTON GROUP – A leading manufacturer of the concrete line pump in China

Get A Free Quote

Mobile:

0086-173-2016-6678

Whatsapp:

0086-173-2016-6678

Email:

sales@ltconcretepump.com