What is the better solution for construction? The answer is the concrete pump. The concrete pump is a popular concrete conveying machine to transport and place mixed concrete at the construction site. But how does a concrete pump work to promote work efficiency?

It is necessary for the operator to figure out the work principles of concrete pumps. Because it is important to make it work efficiently and find out the potential risk. In this way, they can fix the general problems when the concrete pumping doesn’t work well.

How Does the concrete ground pump work?

Concrete ground pumps, also called concrete line pumps or fixed concrete pump, place concrete via the extended pipelines running along the ground. Actually, the ground line pump can reach 150 meters vertically and more than 1000 meters horizontally.

If you are undertaking commercial concrete projects, the concrete pump machine is a better solution. Or, when you are working on residential constructions involving concrete infusion, it is also bettter to use concrete ground pump rather than a wheelbarrow.

Here are mainly three different types of concrete ground pump: Concrete trailer pump, concrete mixer pump, truck-mounted concrete pump (here refer as the static pump with a truck chassis).

Concrete trailer pump and truck-mounted concrete pump are similar. Both of them need an extra mixer truck to discharge the ready mixed concrete to the hopper of the pump machine.

First, the concrete pump will suck concrete material out of the hopper into the pumping system. Later, it will push concrete into the pipelines through S-Valve.

The concrete mixer with a pump is able to mix cement by itself because it has a mixer drum. Therefore, it doesn’t need another large mixer truck to convey wet concrete.

The work of mixing and pumping on-site saves much time and labor.

How does the concrete boom pump work?

Not like the concrete line pump, the concrete boom pump doesn’t need a pipeline extended along the ground.

Mounted on the rear of the vehicle chassis, the concrete pumping machine is mainly to facilitate the unloading of the concrete to the placing area.

First, the concrete mixer discharges concrete to the hopper of the small concrete pump truck. Then the Pumping Machine presses the concrete to the conveying pipe and discharges it through the terminal hose.

What’ more, the expansion and retraction of each boom reset on each boom cylinder to complete. Among them, the elevation angle of the first boom can swing in 2° – 90°, and the second and the third boom can swing at 180°.

It’s necessary to mention that the fourth section boom can be expanded in turn, and the movement of the fourth boom is more frequent in construction. The swing-angle range of this section is about 240°.

At last, in the process of concrete construction, the end of the hose should be as close as possible to the pouring part. And the boom can be driven by a rotary motor and reducer to rotate 365 ° around the fixed turret.

After the construction is completed, the boom can be retracted in the reverse order of the original operation.

How Does the Pumping System work?

The concrete trailer pump is a hydraulic double cylinder piston type pump, which is driven by an electric or diesel motor. The pump system adopts a closed oil circuit, constant power control, and concrete conveying volume adjustment.

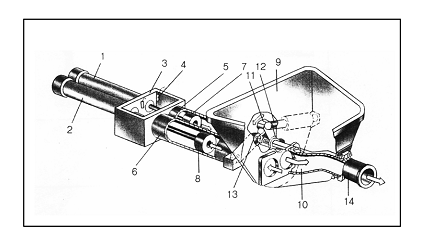

(1)(2) main oil cylinder ; (3) water tank ; (4) reversing device; (5)(6) concrete cylinder; (7)(8) concrete piston; (9) hopper; (10) distribution valve; (11) swing arm; (12)(13) swing cylinder; (14) concrete outlet

First, the concrete piston is respectively connected with the piston rod of the main oil cylinder. Under the action of the hydraulic oil of the main oil cylinder, one cylinder moves back, while the other cylinder moves forward.

Second, the outlet of the distributing valve connects with the outlet. The other end connects with the swinging arm through a spline shaft and can swing left or right under the action of the swinging oil cylinder.

Then, when pumping concrete materials, the concrete piston advances, the concrete piston retreats under the action of the main cylinder.

At the same time, under the action of the swinging cylinder, the distribution valve connects with the concrete, and the concrete cylinder connects with the hopper.

In this way, the concrete piston backward, then the concrete in the hopper into the concrete cylinder, concrete piston forward, the concrete cylinder send material into the distribution valve pump.

When the concrete piston retreats to the end of the stroke, the reversing device in the water tank is triggered. Again, the main oil cylinder is reversed to start continuous pumping.

The main oil cylinder changes direction simultaneously swings the oil cylinder to change direction. Then the distribution valve connects with the concrete cylinder, and the concrete cylinder outlet connects with the hopper.

At this time, the piston retreats and goes forward, achieving continuous pumping.

When the reverse pumping starts, in the suction process, the distributing valve connects one concrete cylinder with the pump outlet. On the contrary, in the push process, the distributing valve will connect this concrete cylinder directly with the concrete hopper. In this way, pump will draw the concrete in the pipeline back to the hopper.

The distribution valve is the key part of the concrete pump, and its type will directly affect the performance of the concrete pump.

Get a Free Quote

Mobile:

0086-173-2016-6678

Whatsapp:

0086-173-2016-6678

Email:

sales@ltconcretepump.com