Small concrete mixer pump is a compact machine that combines concrete mixing and pumping into one integrated unit. By replacing the traditional setup of using a separate mixer and trailer pump, it allows contractors to complete feeding, mixing, and pumping in a continuous and efficient process.

Featuring a mixing drum, a hydraulic pumping system, and either a diesel engine or electric motor, this equiment is designed for small to medium construction projects such as house building, rural construction, and narrow job sites. With typical capacities of 30-40 m³/h, it provides stable performance and consistent concrete output.

Because of its mobility, low investment, an high practicality, a small concrete mixer pump has become one of the most popular choices for contractors looking to improve productivity in small-scale concrete works.

Popular Small Concrete Mixer Pump Models

To help contractors choose the right machine for different projects, here are the most popular small concrete mixer pump models widely used in residential construction, rural housing, and small commercial works. Each model combines compact strucure, stable pumping performance, and efficient mixing capability.

JBS30 – 30m³/h Small Concrete Mixer Pump

Small concrete mixer pump JBS30 offers a balanced capacity with very low operating cost, making it a perfect entry-level choice for small contractors.

This model is best for small house projects, village construction, short-distance pumping.

| Output | 30m³/h |

| Max. pumping pressure | 6-10 MPa |

| Engine Mode | Diesel/Electric |

| Suitable for | 1-2 storey rural houses |

| advantages | low fuel consumption, easy transportation |

| Mixer Type | Drum Mixer |

JBS40 – 40m³/h High-Performance Small Concrete Mixer Pump

With strong pumping power and higher efficiency, JBS40 small mixer pump is ideal for contractors who need consistent output and faster completion times.

JBS40 concrete mixer pump is suitable for larger rural houses, small commercial buildings, continuous pouring jobs.

Drum Mixer Pump

| Output Capacity | 40m³/h |

| Max. pumping pressure | 10 MPa |

| Available types | Diesel/ Electric |

| Suitable for | beams, slabs, colums, and foundations |

| feature | higher productivity for bigger workloads |

| Mixer Type | Drum Mixer |

Twin-shaft Horizontal Mixer Pump

| Output Capacity | 40m³/h |

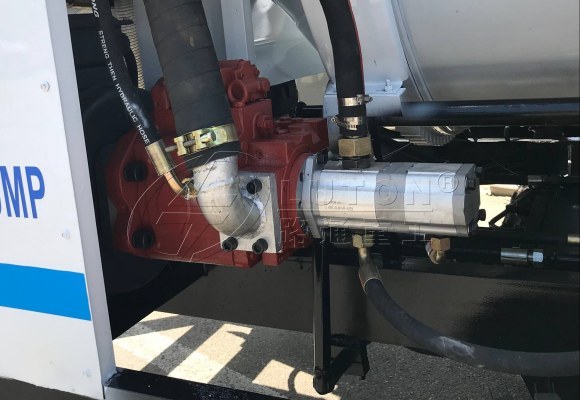

| Main oil pump discharge | 112 ml/r |

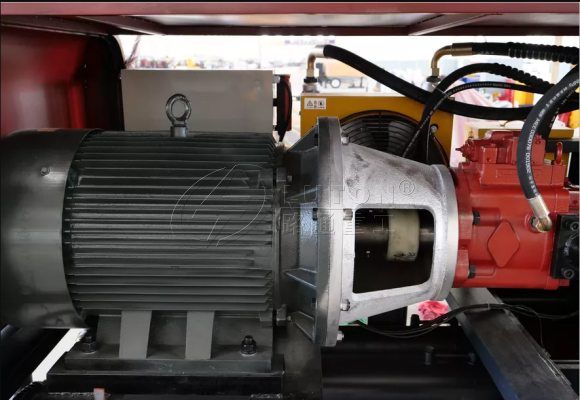

| Main engine power | 45kW (electric motor) 129kW (diesel engine) |

| Concrete cylinder diameter×stroke | Φ200×1000 mm |

| PLC unit | Omron |

| Mixer machine | JS500/JS750 |

Planetary Mixer Pump

| Output Capacity | 40m³/h |

| Max. pumping pressure | 10MPa |

| Concrete cylinder diameter × stroke | Φ200 × 1000 mm |

| Main engine power | 82kW/129kW |

| Pumping distance (vertical/horizontal) | 120m / 400m |

| Mixer machine | planetary mixer 750 or 1000 |

Diesel Type Small Concrete Mixer Pumps

Diesel small concrete mixer pumps are best for areas with unstable or limited electricity. They are featured as strong power output, excellent mobility. They are more suitable for remote or mountain construction sites.

Electric Type Small Concrete Mixer Pumps

Electric small concrete mixer pumps are suitable for urban projects or sites with reliable power supply. They are featured as lower operating cost, quiet and eco-friendly, stable and smooth pumping performance. They are widely used in residential areas, indoor sites, city construction and so on.

Why Choose a Small Concrete Mixer Pump

A small concrete mixer pump delivers far more value than traditional mixing and pouring methods. It is designed to solve the biggest challenges faced in small and medium construction projects – limited labor, tight budgets, narrow job sites, and demanding schedules.

Two Functions in One Machine – Work Twic as Fast

By combining mixing and pumping in a single compact unit, contractors eliminate the need for a separate mixer, trailer pump, and additional workers. It enables a continuous workflow – feed, mix and pump without interruption – dramatically boosting productivity on any job site.

Compact & Mobile for Any Narrow or Remote Location

Large machines struggle in rural areas, alleys, backyards, and indoor sites – but a small concrete mixer pump fits easily. Its lightweight structure and fast mobility make it the ideal solution where big equipment cannot enter but concrete is still required.

Low Investment, High Profit – Quick Payback

The small concrete mixer pump machine costs far less than purchasing two separate pieces of equipment. Lower fuel consumption, fewer workers, and minimal maintenance mean most contractors achieve full ROI within 3-6 months, even with small daily workloads.

Better Concrete Quality with Continuous Pumping

Compared with manual mixing and wheelbarrow transport, small mixer pump ensures consistenent concrete quality and stable delivery.

Continuous concrete pumping can reduce cold joints, improve structural integrity, and speed up every pour.

Easy to Operate

The control panel is simple, user-friendly, and designed for small teams. Even operators with limited technical skills can run the small machine confidently, reducing labor cost and training time.

Versatile for Multiple Uses Across Small Projects

From foundations, slabs, beams, and columns to small commercial builds, driveways, and rural housing, a small concrete mixer pump can handle almost every concrete-related task, ensuring higher machine utilization and maximum value.

Why Choose LUTON Small Concrete Mixer Pumps

Choosing LUTON small concrete mixer pumps means reliable quality, fast delivery, and lifetime support from a professional manufacturer.

Manufacturing Advantages

- Strict quality control and full-load testing

- Durable frame, upgraded mixing drum, and stable hydraulic system

- High pumping efficiency with low maintenance requirements

Globale Shipping

We ensure safe and on-time shipping delivery.

- Exported to 100+ countries

- Secure packing and fast delivery

- Flexible shipping options with complet documentation

After-sales Support

We help you keep the machine running smoothly from day one.

- 24/7 online technical assistance

- Installation guidance and operation training

- Quick dispatch of spare parts

Applications of Small Concrete Mixer Pumps

A small concrete mixer pump is designed to handle a wide range of small and medium construction tasks. Its compact size, stable output, and integrated mixing-pumping design make it a highly versatile machine for both rural and urban projects. Here are the most common applications where small concrete mixer pump delivers outstanding results.

Rural House Construction

Small concrete mixer pumps are widely used in village and township housing projects. They can easily handle:

- Foundations

- Tie beams and ring beams

- Columns and walls

- Roof slabs

Because rural sites often have narrow roads and limited labor, this kind of compact mixer pump machine becomes the most practical solution for fast and consistent concrete placement.

Urban Residential Projects

In city environments where space is restricted, the machine’s small footprint allows it to operate in:

- Courtyards

- Backyards

- Indoor areas

- Tight residential zones

Electric models are especially suitable due to low noise and zero emissions.

Small-scale Commercial Buildings

For shops, small warehouses, office extensions, and renovation projects, the small mixer pump offers stable output without the need to hire larege pumping equipment, helping contractors reduce cost and time.

Road, Foundation, Slab & Driveway Work

The continuous mixing and pumping capability makes it ideal for:

- Concrete pavements

- Floor slabs

- Garages

- Driveways

- Drainage channels

- Small bridges and culverts

Its ability to pump concrete steadily ensures smooth finishing and better structural quality.

Mountain, Remote & Narrow Construction Sites

In mountainous or remote areas where concrete trucks cannot reach, a diesel small concrete mixer pump provides reliable performance. Its mobility and self-sufficient power source make it suitable for:

- Hillside houses

- Remote rural projects

- Hard-to-access locations

- Temporary construction sites

Contractors can produce and pump concrete on-site without relying on external suppliers.

Small Concrete Mixer Pump vs. Traditional Equipment

Contractors often compare a small concrete mixer pump with manual mixing, a standalone trailer pump, or a mixer truck. The differences are significant. The integrated mixing-and-pumping design allows this compact machine to outperform traditional methods in efficiency, cost, and labor requirements.

| Feature | Small Concrete Mixer Pump | Manual Mixing/Trailer Pump | Self Loading Mixer + Pump |

| Function | mixing + pumping in one | separate process | two separate machines |

| Labor Needs | 2-3 people | 5-8 people | 2-3 people |

| Efficiency | High | Low-Medium | High |

| Investment Cost | Low | Medium | High |

| Ideal Projects | Small-Medium | Very Small | Medium-Large |

Mixer Pump vs. Manual Mixing and Wheelbarrow

Traditional approach requires multiple workers, running a slow progress. Under this condition, concrete quality is inconsistent.

By small concrete mixer pump, thanks for its automated mixing and pumping characteristics, it ensures faster casting of slabs, beams, and foundation, with less workforce cost and better consistency.

Mixer Pump vs. Self Loading Concrete Mixer + Pump

There is also another efficient combination which is more suitable for medium or large projects. It is self-loading mixer and pump combination. The two machines needs at least two operators, higher investment larger footprint. They are not suitable for small or medium projects.

Regarding small concrete mixer pump, it is more affordable for small contractors. Fewer machines mean less maintenance and operation costs. Featured as compact structure and easier operation. So, it is best for small and medium pours.

How to Choose the Right Small Concrete Mixer Pump

Choosing the right small concrete mixer pump depends on the project scale, concrete requirements, power conditions, and jobsite environment. The following factors will help you select the most suitable model for your construction needs.

Diesel or Electric – Choose Based on Power Supply

Diesel Small Concrete Mixer Pump

- Best for rural, remote, or outdoor areas

- No dependence on electricity

- Stronger power output

- Ideal for mountain projects and long-distance pumping

Electric Small Concrete Mixer Pump

- Lower operating cost

- Quiet and eco-friendly

- Suitable for urban residential zones and indoor work

- Requires stable power supply

If your site has limited electricity, the diesel small concrete mixer pump is the safer choice.

Select Proper Output Capactiy

- 30 m³/h models are ideal for small houses, village construction, and short daily pours.

- 40m³/h models are recommeded for larger rural houses, small commercial buildings, or continuous slav and column pouring.

Choosing a capacity that matches your workload ensures better efficiency and prevents machine overload.

Evaluate Jobsite Conditions

When choosing your ideal model, consider the following aspects of the jobsite conditions:

- Road width

- Turning space

- Availability of materials

- Foundation stability

- Transport distance

Narrow or hard-to-access locations often benefit most from compact diesel models.

Confirm the Concrete Mix Requirements

Different concrete mixes require different pumping performance. Small concrete mixer pumps generally handle: standard concrete, fine aggregate concrete, as well as pable mixes for slabs and foundations.

If your project requires special aggregates, consult the manufacturer for compatibility.

Check After-sales Support and Spare Parts Availability

Choosing a reliable supplier ensures:

- Fast spare parts delivery

- Professional technical support

- Stable long-term operation

Good service significantly reduces downtime and maintenance cost.

Small Concrete Mixer Pump Price Guide

The price of a small concrete mixer pump varies significantly depending on factors such as capacity, power source (diesle or electric), configuration, and included features. The following guidelines will give you a clear reference.

Price Range of Small Concrete Mixer Pumps

Entry-level compact small concrete mixer pump models ( basic version with lower capacity and simple configuration): $18,000 – $22,000.

Diesel or electric drum-type mixer pumps ( medium-range drum mixer + pump combination): $21,000- $28,000

High-end models with advanced configurations (e.g., higher pumping pressure, larger output capacity, longer pumping distance, or twin-shaft mixing systems): $25,000-$40,000+

Mini mixer + mini pump combinations

Budget-friendly starter units from some suppliers with lower-priced options available, but usually limited in capacity, pumping distance, and long-term stability.

Note:

Lower-priced models may typically come with limited capacity and basic configurations. They may work for very small projects or occasional use, but for long-term construction or frequent pouring, mid-range or high-range models are strong recommended.

Key Factors That Affect the Price of Small Mixer Pumps

There are some crucial factors affecting the price of small mixer pumps, such as output capacity, power source, pumping and mixing performance, quality and service and so on.

Output Capacity

Higher output models naturally cost more due to larger cylinders, stronger hydraulics, and bigger mixer drums.

Power Source

Diesel models are more adaptable to remote worksites or areas with unstable electricity. This kind of power engine is typically built with more robust components.

Electric models are preferred in cities or indoor environments with lower noise, lower energy cost, and eco-friendly operation.

Pumping Power & Pumping Distance

If your project requires long horizontal or vertical pumping (such as multi-story buildings), the pump needs stronger hydraulics and reinforced components – raising the price.

Mixer Type & Drum Capacity

Mixer drum size, mixer types, mixing efficiency, and concree uniformity influence the configuration cost. More advanced mixing systems mean higher price.

Build Quality, Brand & After-sales Support

Brands with strong manufacturing capability, certifications, and reliable after-sales service command higher prices but also provide better durability and lower long-term maintenance cost.

Shipping & Export-Related Costs

For international buyers, costs such as freight, insurance, customs clearance, and export packaging also affect the final pricing.

Customization & Optional Features

Add-ons such as:

- Automatic feeding system

- Remote control

- Enhanced electrical control unit

- Corrosion-resistant coatings

- Enlarged hopper

- Stronger pumping arm

- …

All the aboved aspects will increase the total price.

How to Interpret the Price for Your Needs

- Small contractors starting out

For building small houses or rural projects, choose basic or mid-range models ($18,000 – $25,000)

- Contractors needing higher efficiency and stable long-term performance

For frequent pouring or larger workloads, choose mid-to-high range models ( $25,000 – $35,000+)

- Remote areas / mountain regions / unstable power supply

For these situations, diesel powered models with strong pumping configuration are recommended.

- Commercial use / rental business / multi-project contractors

Investing in premium high-configuration models ensures fast ROI and reliable performance.

Export Cases of LUTON GROUP

HBTS30 Concrete Pump Sold To Panama

HBTS40 Concrete Pump To Ethiopia

Concrete Pump In Pakistan

Concrete Pump Indonesia

Concrete Pumps In India

Concrete Trailer Pump For Sale Australia

HBT90 Diesel Concrete Trailer Pump To Armenia

Concrete Mixer Pump Exported To Sierra Leone

Concrete Mixer Pump Exported To Kenya

LUTON Concrete Trailer Pump To Brunei

Concrete Trailer Pump To Jamaica