Distribution valves of concrete pumps are various. Choose the right type is crucial for the whole concrete pumping system. Concrete pump equipment is usually consisted of mobile chassis, pumping system and pumping pipeline (or pumping boom), among which pumping system is the core of the whole pump machine.

Further, the distribution valves of concrete pumps system is the key to stable and continuous operation of the pump and realization of the pumping function.

Then what types of distribution valves are commonly used in currently concrete pump equipment, and which one is better to use and easier to maintain? You may find the answers in this article.

Working Principle of Distribution Valves Types in Concrete Pumps

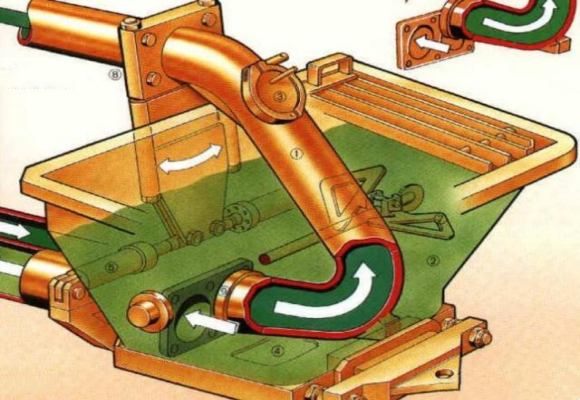

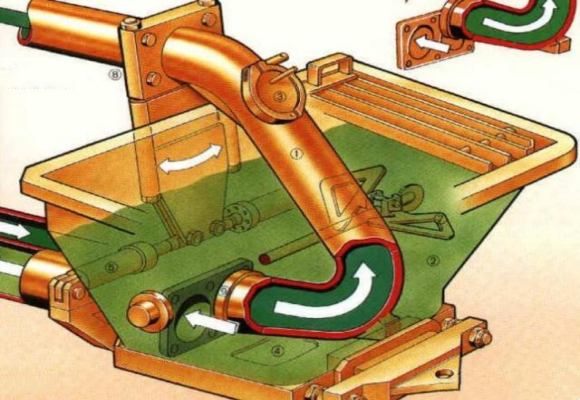

In the concrete hopper, the distribution valve swings left and right driven by hydraulic swing rods to alternately connect the two concrete cylinder and the outlet of the pumping machine.

Then driven by the hydraulic swing cylinder piston, the concrete material is pumped out or sucked into the concrete cylinder.

Types of Distribution Valve of Concrete Pumps

Distribution valve is a crucial component in concrete pumping machine, which is used to control the concrete flowing way in hopper, concrete cylinders and pipeline. It directly affects the structure form, sucking performance, pressure loss and application ranges of a concrete pump equipment. According to statistics, 90% of concrete blockage failures occur at distribution valve.

There are three main types of valves: rotary valve, gate valve and tubular valve. By far, gate valve and tubular valve are widely used in various concrete pumps.

Gate valve is usually used in concrete trailer pump, divided into inclined type and horizontal type according to the different structures.

It has strong shearing ability and can pump concrete materials with low slump. Also, as the gate valve is set under the hopper, which can avoid the concrete segregation and has better suction performance.

But the sealing performance of the gate valve is poor, not suitable for high-pressure and long-distance pumping work.

In addition, the two discharge holes of the gate valve need a Y-shaped pipe, whose conveying performance is poor and easy to block.

At last, the board is easy to be stuck leading to seal and poor material absorption.

The tubular valve is not only the distribute valve, but also a part of the concrete conveying pipeline. Tubular valve can be divided into three types: horizontal s-shape valve, vertical v-shape valve and skirt-shape valve.

It is equipped in the hopper. In pumping process, the discharge end always connects with the conveying pipeline, and the feed end swings according to the glasses plate, alternately connecting to the two concrete cylinders. The cylinder connected to the tubular valve is in the discharge stroke and the other one not connected to the valve sucks concrete materials in the hopper.

C-shaped Valve

C valve also known as trunk valve is a patented technology of Putzmeister, which is mainly used on concrete pump trucks. It is also one of the leading technologies of Putzmeister in concrete machinery in the early days.

The c-shaped distribution valve is mainly used in the concrete boom pump truck, which can lead the concrete material to the boom through a short passage. One cylinder connected to the hopper is in the feeding state, the other one is in the pumping state, connect with the c-shape valve directly to the discharge port of the concrete pump truck.

By the swing valve oil cylinder, the feed port of the c-shape valve alternately connects to the two concrete cylinders to suck and pump concrete material.

This c-shape tube valve has a smaller curvature radius at the lower curve, so the resistance is larger. In addition, there may be coarse aggregate accumulation between the c-shape tube and the hopper wall. All these may cause difficulty in swinging. Although the c-shaped tube valve has its own shortcomings, it is still widely used in trailer pumps and pump trucks due to the structural advantages and repair advantages.

Skirt Valve

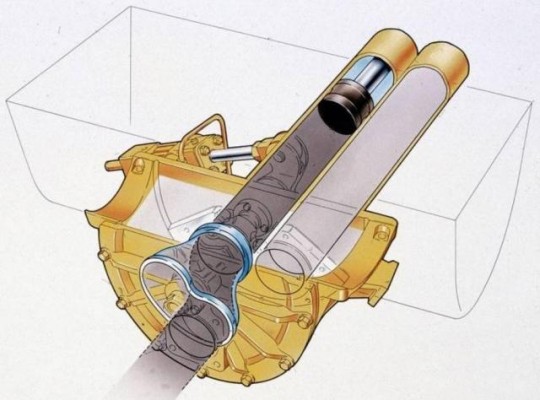

Skirt valve is a patented technology owned by SCHWING, which appeared in SCHWING concrete pump truck in 1982. Due to the monopoly of Putzmeister’s C-valve patented technology at that time, Schwing had to find another way. Finally, they succeeded in designing their own “skirt valve”, which was mainly used in pump trucks and truck-mounted pump.

This kind of valve shapes like a trumpet skirt. The discharge end is big and the input end is small.

The discharge end of skirt valve does not coincide with the rotation axis, and has a radius of gyration.

When pumping, the swing shaft of the skirt valve crosses the supporting of the rear wall plate supporting of the hopper, and the skirt valve swings driven by the oil cylinder, swinging both the front and rear surface of the skirt valve.

The skirt valve has smaller rotary resistance than common s-shape valve, and the gap between the cutting ring and the glasses plate can be automatically compensated. With short valve body, big inner diameter and small pressure loss, convenient cleaning way, the possibility of blockage in skirt valve is greatly reduced.

S-shaped Valve

Among the three types of distribution valve, s valve is now used most widely in all kinds of concrete vehicles including concrete boom pump trucks, concrete trailer pumps and concrete line pump trucks. The technology is more mature and the market share is also more.

The valve body is s shape, the thickness of the wall is also changed greatly, and the wall thickness is also large where the wear is large. The rocker arm shaft is connected with the rocker arm. When the rocker arm shaft passes through the hopper, there is a set of seals for sealing.

The three kinds of pipe valves have their own characteristics and advantages. In a comprehensive comparison, the s valve known for its longer-term using experience, good practicability, stability and excellent pumping capacity, is used in various concrete pumping systems most widely.

Comparison on Different Types of Distribution Valves

| Distribution Valve | Advantages | Disadvantages |

| S-shaped Valve | 1. Stable performance most widely used in pump truck, boom truck and pump trailer. 2. Equipped Glasses plate and cutting ring with wear-resistant alloy material. 3. Controlling gap by rubber spring ensure. 4. Reliable sealing performance | 1. Higher risk of blockage due to the small bend radius. 2. Poor concrete flowing performance, and large pumping resistance. |

| Skirt Valve | 1. Small feeding port and large discharging port, in the shape of a horn. 2. Hardly bending leads to less resistance and better fluidity. 3. Stronger sealing performance ensures higher pumping pressure. | 1. Large body occupies large space in hopper. 2. More resistance concrete as swing in hopper. |

| C-shaped Valve | 1.the mechanism that controls the swing of the C valve is located above the hopper and is not easily corroded by concrete. So it has longer service life and better stability. 2.Better sealing performance. 3.Convenient to repair and maintain. | 1. Smaller curvature radius at the lower bend leads more resistance in pipeline. 2. Coarse aggregate accumulation between the c-shape tube and the hopper wall may cause difficulty in swinging. |