The Middle East has become a hub for large-scale commercial developments, including shopping malls, office towers, and mixed-used complexes. With rapid urbanization, population growth, and rising construction investments, demand for efficient and reliable concrete pouring solutions has surged. Traditional concrete pouring methods are no longer sufficient for modern projects that demand speed, accuracy, and structral integrity. A concrete pump for commercial complex projects in the Middle East provides contractors with the ability to meet strict timelies while ensuring premium construction quality.

| Model | HBT90-22-199R |

| Output Capacity | 90m³/h |

| Pumping Pressure | 20 Mpa |

| Distribution Valve | S valve |

| Concrete Cylinder | Ф200*1600 |

| Diesel Engine Model | Weichai 199kW |

| Conveying Distance | 300m/1200m |

| Aggregate Diameter | Scree:40mm |

| Model | LT5339THB |

| Pumping Capacity | 200m³/h |

| Pumping Pressure | 8.8 Mpa |

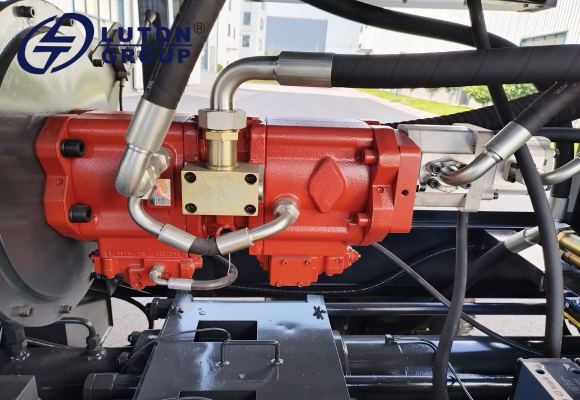

| Hydraulic System | close |

| Folder Type | 6RZ |

| Boom Vertical Height | 51.3m |

| Boom Horizontal Length | 46.3m |

| Turnable Rotation Angle | ±360° |

What Is A Concrete Pump For Commercial Complex Projects

A concrete pump is a machine designed to transport liquid concrete through pipelines directly to the pouring site. This technology reduces reliance on manual labor and eliminates delays caused by crane-based methods. For commercial complex projects – where large volumes of concrete must be poured quickly and precisely – concrete pumps are indispensable.

There are three types of pumps widely used in moden construction sites:

- Boom Concrete Pump – ideal for high-rise or multi-level complexes due to long reach and flexbility.

- Trailer Concrete Pump- best for large-volume horizontal pours, foundations, and slabs.

- Concrete Mixer Pump – combines mixing and pumping, suitable for medium-sized commercial projects.

Each pump type serves different project needs, making equipment selection a critical decision for clients.

Key Specification For Commercial Complex Construction

When selecting a concrete pump for commercial complex projects, contractors should evaluate key specifications that directly affect project performance:

- Pumping Capacity – Determines how much concrete can be delivered per hour. High-rise and large-scale projects typically require pumps exceeding 60m³/h.

- Pumping Pressure – Ensures concrete can be pumped to upper floors or extended distances without losing flow consistency.

- Boom length – A crucial factor for high-rise commercial towers, as it allows concrete to reach higher floors without repositioning the pump.

- Engine type – Diesel pumps are best suited for remote or unstable power supply sites, while electric pumps are ideal for urban projects with reliable electricity.

These specifications influence efficiency, cost-effectiveness, and the overall structural quality of commercial complexes.

Concrete Pump In A Middle East Commercial Project

In Riyadh, Saudi, Arabia, a major commercial complex project involved the cosntruction of a shopping mall with a 12-story office tower. The contractor faced challenges such as large-scale foundations, high daily concrete demand, and strict deadlines. To overcome these, they deployed the HBT90 trailer concrete pump for foundations and slabs, and a 52m boom pump for high-rise delivery.

- Daily Output – Over 80m³ of concrete pumped without interruption.

- Vertical Reach – Efficient delivery of concrete up to 50m

- Project Timeline – Construction was completed 25% faster compared to traditional pouring methods.

The strategic combination of trailer and boom pumps provided both high output and flexibility, ensuring smooth progress throughout different construction phases.

Benefits Of Using A Concrete For Commercial Complex Projects

Contractors and developers gain several advantages by using concrete pumps in commercial projects:

- Efficiency – faster and more reliable pouring across large areas and multiple floors.

- Cost Savings – reduces reliance on manual labor and minimizes material wastage.

- Consistency – Gurantees uniform concrete placement, essential for long-lasting and safe structures.

- Safety – Minimizes the risk of workplace accidents by reducing heavy manual handling.

- Versatility – Suitable for foundations, slabs, columns, and multi-level pours.

Concrete Pump Price In The Middle East

The cost of a concrete pump for sale in the Middle East varies widely depending on pump type, capacity, and specifications:

| Concrete Pump Types | Price Range |

| Concrete Mixing Pump | $18,000-$44,000 |

| Trailer Concrete Pump | $18,000-$38,000 |

| Boom Concrete Pump | $90,000-$450,000 |

Factors that influence pricing include pumping capacity, maximum pressure, boom length, engine type, brand reputation, and after-sales service availability. While the initial investment can be significant, the long-term ROI is high due to reduceed labor and faster projects turnover.

Choosing The Right Concrete Pump For Your Project

Selecting the right concrete pump requires careful evaluation of project needs:

- Project Size – Large-scale complexes benefit from high-capacity trailer or boom pumps.

- Site Conditions – Remote or off-grid projects often require diesel pumps, while urban projects may use electric models.

- Budget & ROI – Contractors should consider not only purchase price but also long-term productivity and efficiency gains.

- Maintenance and Support – Reliable after-sales service ensures pumps operate smoothly throughout the project lifecycle.

Customer Testimonials And Feedback

A project manager from the Riyadh complex shared:

The HBTS90 trailer pump and 52m boom pump allowed us to meet strict deadlines without compromising quality. Their efficiency and reliability were crucial for completing such a large commercial project on time.

Another contractor from Dubai added:

We switched to using a boom concrete pump for our multi-level commercial complex, and it has transformed our workflow. The speed and accuracy have helped us save both time and money.

Future Outlook For Concrete Pumps In The Middle East

With continuous investments in infrastructure and real estate, demand for concrete pumps in the Middle East is expected to grow steadily. Mega projects like smart cities, luxury malls, and commercial hubs will rely heavily on hig-capacity concrete pumps to maintain construction speed and quality standards. Contractors who adopt modern pumping solutions will gain a competitive advantage in delivering projects efficiently.

Best Concrete Pump Supplier In The Middle East

The success of commercial construction projects in the Middle East depends heavily on efficient and reliable concrete delivery. Choosing the right concrete pump for commercial complex projects helps contractors save time, reduce costs, and ensure structural durability.

If you are looking for a concete pump for sale in the Middle East, contact our expert team today for trailored specifications, competitive pricing, and reliable after-sales support.

Export Cases Of LUTON GROUP

HBTS30 Concrete Pump Sold To Panama

HBTS40 Concrete Pump To Ethiopia

Concrete Pump In Pakistan

Concrete Pump Indonesia

Concrete Pumps In India

Concrete Trailer Pump For Sale Australia

HBT90 Diesel Concrete Trailer Pump To Armenia

Concrete Mixer Pump Exported To Sierra Leone

Concrete Mixer Pump Exported To Kenya

LUTON Concrete Trailer Pump To Brunei

Concrete Trailer Pump To Jamaica