Bridge construction requires durable and high-performance equipment to handle continuous concrete pouring over long distances. Traditional methods often struggle with efficiency and consistency, leading contractors to rely on a concrete pump for bridge construction. This case study highlights how our HBT90 trailer concrete pump was successfully applied in a bridge in the Philippines.

Long-distance Capability

High Pressure For Smooth Flow

Fuel Independence With Diesel Power

Exceptional Durability

Project Background

The project involved building a 500m-long concrete bridge in Central Luzon, Philippines. Challenges are obvious:

- Pumping concrete across long horizontal distances.

- High-strength concrete with coarse aggregates.

- Working under humid tropical conditions with limited downtime allowed.

The contractor required a high-pressure trailer pump capable of long-distance pumping with stable output.

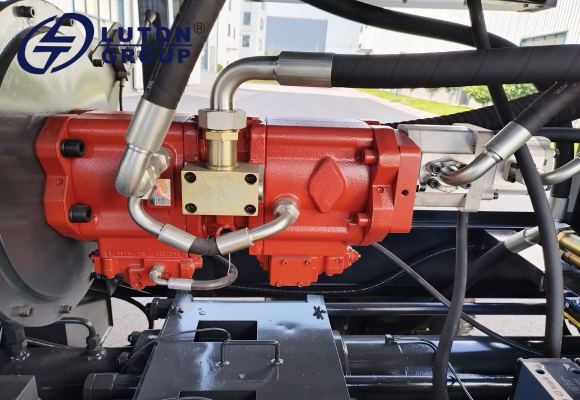

HBT90 Concrete Pump For Bridge Construction In The Philippines

The HBT90 concrete pump was chose for this bridge construction in the Philippines as its robust performance, strong diesel engine, and ability to handle large-scale infrastructure projects.

| Model | HBT90 Trailer Concrete Pump |

| Max. Output | 90 m³/h |

| Pumping Pressure | 16MPa |

| Vertical Conveying Distance | 200m |

| Horizontal Conveying Distance | 1200m |

| Engine Power | 140kW diesel engine |

| Max. Aggregate Size | up to 50mm |

Application And Performance

The pump was set up near the batching plant and connected to long pipelines stretching across the bridge span. Results achieved:

Efficiency: Delivered 80-90m³ of concrete daily, keeping up with the demanding construction schedule.

Long Distance Pumping: Maintained stable flow up to 900m horizontally without blockages.

Durability: Operated reliably under high humidity and heat, with consistent pressure throughout the project.

Cost Efficiency: The use of HBT90 diesel trailer pump helped the contractor achieve cost efficiency at multiple aspects.

- 20% reduction in concrete wastage due to accurate pumping.

- 35% savings in labor costs compared to manual transport.

- Shorter projects duration, reducing overall operation expenses.

Customer Feedback

The project engineer in the Philippines noted:

The HBT90 concrete pump exceeded our expectations. Its powerful pumping pressure and reliability were critical in completing the bridge project on time. It worked perfectly even in tough tropical conditions.

Why Choose A Concrete Pump For Bridge Construction

When it comes to bridge construction, efficiency, precistion and reliability are critial. Traditional concrete pouring methods often face limitations in terms of distance, speed, and labor intesity. A concrete pump, however, offers a modern solution that overcomes these challenges, making it the preferred choice for contractors working on complex bridge projects. Here are the main reasons:

Long-distance Capability

Bridge spans are usually long and elevated, making it difficult to transport concrete manually or with traditional equipment. A concrete pump can deliver concrete across extended horizontal distances and heights, ensuring uninterrupted supply to the exact pouring point. This minimizes loss and speeds up projects timelines.

High Pressure For Smooth Flow

Bridge often require high-strength concrete mixes with lower water content, which are denser and harder to move. Thanks to their high-pressure pumping system, concrete pumps can handle these mixes with ease, guranteeing a consistent and smooth flow that ensures the structural integrity of the bridge.

Fuel Independence With Diesel Power

Many bridge projects are located in remote or underdeveloped areas where electricity is unavailable. A diesel-powered concrete pump provides complete independence from the grid, ensuring continuous operation without downtime, even in challenging environments.

Exceptional Durability

Bridge construction is demanding, with long working hours, heavy workloads, and rough site conditions. Concrete pumps are engineered with robust materials and advanced designs that allow them to withstand harsh environments, resist wear, and maintain reliable performance over extended periods.

Conclusion

This project in the Philippines demonstrates how the HBT90 trailer concrete pump is a reliable solution for large-scale infrastructure like bridges. Using a concrete pump for bridge construction ensures efficient concrete delivery, reduced costs and superior structrual quality.

If you are looking for a concrete pump for sale for bridge or infrastructure projects, reach out to our sales team for technical specifications and a customized quotation.

Export Cases Of LUTON GROUP

HBTS30 Concrete Pump Sold To Panama

HBTS40 Concrete Pump To Ethiopia

Concrete Pump In Pakistan

Concrete Pump Indonesia

Concrete Pumps In India

Concrete Trailer Pump For Sale Australia

HBT90 Diesel Concrete Trailer Pump To Armenia

Concrete Mixer Pump Exported To Sierra Leone

Concrete Mixer Pump Exported To Kenya

LUTON Concrete Trailer Pump To Brunei

Concrete Trailer Pump To Jamaica