Concrete pump accidents refer to accident that occur during the use of concrete pumps. It is essential to be familiar with the situations that may lead to accidents before using the pump. LUTON GROUP specializes in various concrete pump methods with high-quality concrete pumping equipment and optimal solutions for different onsite applications, helping customers avoid variety of concrete pump accidents and unnecessary lose in advance.

Types of Concrete Pump Accidents

Concrete Splash Injury

During the process of concrete pumping, it is possible for concrete to splash and injure people due to pipeline blockage or improper operation.

Preventive Measures

- Before pumping concrete, the pipeline should be checked for unobstructed flow.

- Operators should wear protective equipment such as safety helmets, protective goggles, protective clothing, etc.

- During the concrete pumping process, keep on observing the pumping situation and any abnormalities should be promptly stopped for handling.

Blocked Pipe

During the process of concrete pumping, due to the lack of understanding of pumping technology by construction personnel or improper concrete mixing ratio, pipe blockage may occur.

Blockage not only affects the construction progress, but may also cause damage to the concrete pump.

Preventive Measure

- Control the amount of remaining material in the hopper

- Reasonably handle concrete

- Control downtime

- Clean the pipeline

- Check the pipeline connections

- Strengthen operator training

- Develop emergency plans

Overturning Or Collapsing

Concrete pump body overturning or collapsing may be caused by unstable foundation, insufficient support, or improper operation.

In a 2020 accident, a concrete pump truck suddenly tilted due to one of its support legs getting stuck in an underground concrete pipeline, causing injuries to workers who were operating it.

Preventive Measure

- Use pump products with optimized structural design to ensure that the frame height and width are moderate, the support legs are stable, and the pumping pipeline length is consistent.

- Improve the operational skills and safety awareness of operators

- Improve the construction site environment and avoid using pumping equipment on rough, steep slopes, or unstable foundations.

- Strengthen safety production management

Concrete Leakage

The concrete pump delivery system may have poor sealing, leading to concrete leakage.

Leakage not only causes resource waste, but may also pollute the environment.

Preventive Measures

- Regularly inspect the conveying pipelines, pipeline interfaces, sealing rings, pipe clamps, and other components to ensure their integrity and reliable confinement.When the sealing ring is found to be aged, damaged, or the pipe clamp is loose, it should be replaced or tightened immediately to prevent leakage caused by poor sealing.

- Optimize pipeline layout and connections

- Strengthen the quality control of concrete

- Pay attention to the details of pumping operation, control the pumping speed, and avoid no-load operation

- Use high-quality accessories

Electric Shock Accident

When the concrete pump truck is working onsite, the boom may touch the high-voltage power lines near the construction site, causing electric shock accidents.

Preventive Measures

- Before carrying out concrete pump operations, carefully inspected the work site to ensure that there are no safety hazards such as high-voltage wires.

- Operators should strictly follow safety operating procedures and avoid carrying out fabric operations near high-voltage power lines.

- If it is necessary to work near high-voltage power lines, take effective insulation measures, such as using insulation pads, insulation gloves, etc.

Mechanical Injury Accidents

Concrete pump trucks belong to heavy machinery equipment, and insufficient skills of operators or equipment failures may lead to mechanical injury accidents.

Operators may be injured during maintenance or cleaning of pump trucks due to misoperation or sudden equipment start-up.

Preventive Measures

- Operators should receive professional skills training and safety training, and be familiar with the operation and maintenance of concrete pump trucks.

- Before carrying out maintenance or cleaning work, ensure that the pump truck has completely stopped running and cut off the power supply.

- Use professional maintenance tools and equipment to avoid accidents caused by the use of inappropriate tools.

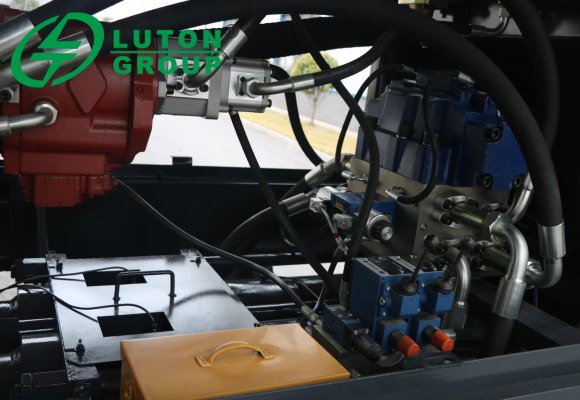

Hydraulic System Malfunction

As one of the core components of concrete pump trucks, hydraulic system failure may cause the pump truck to malfunction or result in serious accidents.

Hydraulic system failures may be caused by high oil temperature, oil contamination, damaged seals, and other reasons.

Preventive Measures

- Regularly inspect and maintain the hydraulic system, including replacing worn seals, cleaning oil tanks and filters, etc.

- Pay attention to controlling the oil temperature to avoid oil deterioration and seal damage caused by excessive oil temperature.

- Use high-quality hydraulic oil and seals to ensure the stability and reliability of the hydraulic system.

Concrete Pump Accident Handling

- Immediate Shutdown

Once a concrete pump accident occurs, the machine should be stopped immediately and the power should be cut off to prevent the accident from escalating.

- Evacuation Personnel

Quickly evacuate personnel from the accident scene to ensure their safety.

- Contact Rescue

Contact a professional rescue team in a timely manner for rescue and handling.

- Accident Investigation

Conduct a detailed investigation and analysis of the accident, identify the causes and lessons learned, in order to take corresponding measures to prevent similar accidents from happening again.

In summary, there are various types of accidents that may occur during the use of concrete pumps, including electric shock accidents, mechanical injury accidents, hydraulic system failures, and concrete splash injuries. In order to ensure construction safety and personnel health, effective preventive measures and accident handling measures must be taken to reduce the probability and impact of accidents. At the same time, in the event of an accident, immediate measures such as shutdown, evacuation of personnel, contact for rescue, and accident investigation should be taken to minimize the losses and impacts of the accident.

Hot Models Of LUTON Concrete Pumps

All in all, during the construction process, concrete pump accidents are something that anyone is not willing to encounter. So when selecting equipment, we should pay special attention to the quality and performance of the equipment, as well as the manufacturer’s supporting services. LUTON GROUP has nearly 30 years of experience in manufacturing and exporting construction machinery, with mature production technology, and comprehensive services. We specialize in providing customers with various concrete pumping solutions, helping to avoid the possibility of various concrete pump accidents in advance and avoid unnecessary losses for customers.

Mini Concrete Pump

High-Pressure Concrete Pump

Concrete Trailer Pump

Concrete Mixer Pump

Concrete Boom Pump