Congratulations! A set of LUTON concrete mixer pump JBS40 and a loader machine LT930 have successfully delivered to South Sudan. This is the third return order from the customer in South Sudan.

| Model | JBS40-10-84R |

| Max. theo. concrete output | 40 m³/h |

| Mixer rated feed capacity | 0.56 m³ |

| Mixer rated discharge capacity | 0.45 m³ |

| Max.concrete pumping pressure | 10 MPa |

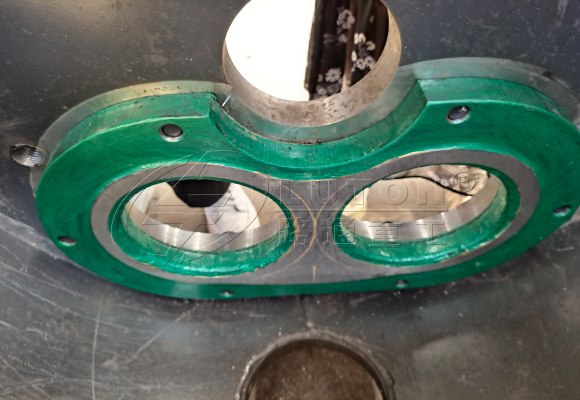

| Distribution valve type | S valve |

| Concrete cylinder diameter×stroke | Φ180/1000 mm |

| Diesel engine model | Weichai 84kW |

| Hydraulic circuit type | open circuit |

| Max. Conveying Distance | 120m vertical 500m horizontal |

| Model | LT930 |

| Bucket capacity | 1 m³ |

| Engine type | YUNNEI 55kW |

| Overall Dimension (L*W*H) | 5500×1800×2200 mm |

| Wheelbase | 2200 mm |

| Wheel distance | 1490 mm |

| Min. ground clearance | 260 mm |

| Total weight | 3200 kg |

| Max. unloading height | 3200 mm |

| Bucket width | 1800 mm |

| Max. lift height | 4400 mm |

LUTON Concrete Mixer Pump And Loader Machine To South Sudan

This customer from South Sudan began their cooperation with LUTON GROUP five years ago. At that time, the region where the customer was located was vigorously promoting infrastructure construction and urgently needed a batch of high-quality concrete equipment to meet the project requirements. Among many suppliers, LUTON GROUP stood out with its extensive product line, professional technical team, and complete after-sales service system. During the first cooperation, LUTON GROUP provided comprehensive support to the customer, including equipment selection, technical training, and after-sales maintenance. Among them, the mixing pumps and self loading concrete mixer trucks performed well at the project site, efficiently and stably completing various construction tasks, significantly improving the construction efficiency and quality.

As time went by, the scale of the projects undertaken by the client continued to expand, and higher requirements were put forward for the performance and quantity of the construction machinery. This time, the client’s order was mainly for the purchase of suitable mixing pumps and loaders for a modern community service center project. Due to the previous pleasant cooperation and trust established between the two parties over a long period of time, as well as the recognition and appreciation for the LUTON products, the client did not hesitate and directly informed the sales specialist of LUTON of the procurement requirements and details. Soon, our technical team would match the JBS40 concrete pump suitable for this project requirement with a flexible and convenient loader.

Concrete Mixer Pump JBS40 Details

High-quality diesel engine from the top brand, Weichai-Deutz, 84kW. With stable performance, it provides powerful energy resource to the whole working process.

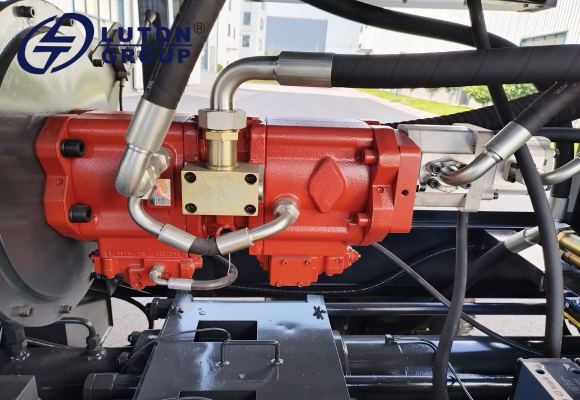

Open type hydraulic circuit equipped with double main oil pump realizes steady energy transmission, high efficiency, low noise and high working pressure.

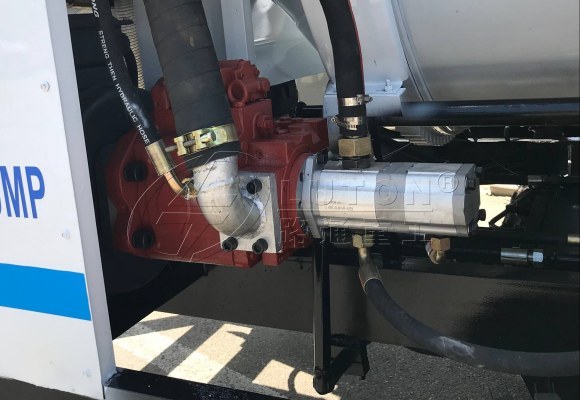

Double gear pump, one for mixing shaft driving in pump hopper, the other for cooling.

Reliable sealing technology from the famous USA brand-Parker, ensures the whole set sealing safely and durably.

Automatic electric lubrication provides lubricants to each lubrication point of the pump at regular intervals in fixed quantities and ensures every part is adequatedly lubricated, reducing wear and faults caused by insufficient or excessive lubrication.

Highly reliable electromagnetic control valve group, with strong safety, fast response speed, simple structure, convenient maintenance, low cost, and strong adaptability to harsh environment, realizes the automatic control of pumping system.

Spectacle plate made up of hard material alloy, can do 30,000-50,000 cubic meters of work, with a strong wear resistance and a long lifespan.

Electronic components from Schneider ensures simple layout, easy operation and maintenance as well as reliable control performance.

Loading Description

| Products | Loading Method | Delivery Time |

| JBS40 Concrete Mixer Pump with 100m Pipleline | 40HQ * 1 for 1 set | 10 working days |

| LT930 Wheel Loader Machine | 40HQ * 1 for 3 sets 20GP * 1 for 1 set | 15 working days |

Related Products

Mini Concrete Pump

High-Pressure Concrete Pump

Concrete Trailer Pump

Concrete Mixer Pump

Concrete Boom Pump