Boom pressure concrete pump, as one of the most efficient concrete pumping equipment in modern construction industry. Thanks to the flexible transportation, telescopic delivering robot arm as well as strong pumping pressure, boom pressure concrete pump plays an irreplaceable role in many complex construction sites which are inaccessible for other kinds of concrete pumps. What is definitely a boom pressure concrete pump? How does it work? What models does LUTON provide? How is these products?

This article comprehensively analyzes the technical advantages, application scenarios, selection recommendations, and core products of boom pressure concrete pumps, providing you with professional reference for selecting construction equipment and helping your project progress steadily.

Get A Free Quote >>What Is A Boom Pressure Concrete Pump

Actually, boom pumps are better known as concrete boom pumps, boom pump trucks, or even concrete pump trucks. These names primarily stem from their distinctive design: a vehicle-mounted mechanical boom. The entire boom pump system is centrally mounted on a large vehicle chassis, allowing for free movement on urban and rural roads. While the vehicle is in motion, the long, multi-section boom is folded and retracted onto the frame. Once at the work site, the frame is secured to the solid ground by its own powerful support system, while the long boom, carrying the delivery pipeline, can extend across a vast three-dimensional space. Therefore, in China, boom pumps have a more poetic name : sky pump.

The word “pressure” here in the title of this article emphasizes the crucial role of its pumping power throughout the boom pumping system. Whether reaching the clouds, plunging deep underground, or flexibly covering large pouring areas, thanks to their powerful pumping pressure, boom concrete pumps enable efficient, stable and continuous concrete delivery in complex terrain and challenging environments.

Small Boom Pressure Concrete Pump

Small Compact Structure

Flexible Pumping Method

Easy Operation

Convenient Transportation

Parameter

| Model | Units | LTB40R-15 | LTB40R-21 |

| Max. theo. concrete output | m³/h | 40 | 50 |

| Max. concrete pumping pressure | MPa | 10 | 10 |

| Distribution valve type | s vavle | s valve | |

| Concrete cylinder diameter | mm | Ф180×1300 | Ф180×1300 |

| Hopper capacity | L | 500 | 500 |

| Outlet diameter | mm | Ф150 | Ф150 |

| Vertical height of boom | m | 15.4 | 22 |

| Radius of place concrete | m | 13-16 | 20 |

| Concrete pipe | m | 125 × 3 | 125 × 3 |

| Tower rotation angle | ° | 200 | 200 |

| Leg open width | m | 5.5 | 5.5 |

| Distribution rod direction control | manually | manually | |

| Diesel engine model | Weichai 82kW | Weichai 82kW | |

| Rotate speed | rpm | 2200 | 2200 |

| Travelling diesel engine | Changchai L32 32HP | Changchai L32 32HP | |

| Tyre | 4 × 8.25 × 16 | 4 × 8.25 × 16 | |

| Max. aggregate diameter | mm | 30 | 30 |

| Inside diameter of delivering pipe | mm | Ф100 | Ф125 |

| Dimension | mm | 7500 × 2200 × 2920 | 7500 × 2200 × 3200 |

Big Boom Pressure Concrete Pump

High Efficient Performance

Easy Pumping Method

Intellignent Control

Wide-range Application

Parameter

| Model | Unit | 30m | 38m | 40m | 47m | 50m | 52m | 56m | 58m | 61m |

| Chassis | Drive mode | 6×4 | 6×4 | 6×4 | 6×4 | 6×4 | 6×4 | 8×4 | 8×4 | 8×4 |

| Diesel Engine | YUCHAI YC6J200-52 | Cummins ISGe5-400 | Cummins ISGe5-400 | Cummins ISGe5-400 | Cummins ISGe5-400 | Cummins ISGe5-400 | Cummins ISGe5-400 | Cummins ISGe5-400 | Cummins ISGe5-400 | |

| Boom Fold Form | 4Z | 5RZ | 5RZ | 6RZ | 6RZ | 6RZ | 6RZ | 7R | ||

| Boom vertical height | m | 30 | 38 | 39.9 | 47 | 49.3 | 51.3 | 56 | 57.1 | 60.8 |

| Boom horizontal length | m | 25 | 33.5 | 35.6 | 42.7 | 44.3 | 46.3 | 50.9 | 52.1 | 55.6 |

| Minimum expanded height | m | 7.1 | 9.1 | 7.7 | 10.3 | 10.6 | 11 | 15.8 | 15.8 | 14.9 |

| Turntable rotation angle | ° | ±210° | ±360° | ±360° | ±360° | ±360° | ±360° | ±360° | ±360° | ±360° |

| Maximum theoretical pumping capacity | m³/h | 85 | 145 | 145 | 200 | 200 | 200 | 200 | 200 | 200 |

| Maximum pumping pressure | MPa | 8.7 | 7.5 | 7.5 | 8.8 | 8.8 | 8.8 | 8.8 | 8.8 | 10 |

| System oil pressure | MPa | 32 | 35 | 35 | 35 | 35 | 35 | 35 | 35 | 35 |

| Hydraulic tank volume | L | 570 | 500 | 500 | 500 | 500 | 500 | 570 | 570 | 800 |

| Delivery pipe diameter | mm | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 |

| End flexible hose diameter | mm | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 | 125 |

| End flexible hose length | m | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

Concrete Mixer Boom Pump

Concrete mixer boom pump, composing of forced mixer and pump truck, automatic feeding, mixing and pumping function modulars, achieves mechanization in construction projects. Adopt forced and double shaft mixer, LUTON concrete mixer boom pump not only is fast in mixing speed, but also performs good in concrete quality.

High Efficient Performance

Easy Pumping Method

Intellignent Control

Wide-range Application

Parameter

| Model | Unit | LT5216THB 21 |

| Overall axle base | m | 3.8 |

| Max. speed | km/h | <30 |

| Wheelbase | m | Front 2.45/back 2.5 |

| Dimension | m | 10.35×2.5×3.3 |

| Spreading Width | m | 4.79 |

| Generator | Engine Mode/Output Power | Straight 6 cylinder/145kW/1800r/min |

| Boom Fold Form | 4 section hydraulic fold | |

| Conveying Pipe Diameter | mm | Ф125 |

| Hose length | m | 3 |

| First section | m/° (length/rotation) | 6.38/0~90 |

| Second section | m/° (length/rotation) | 4.65/0-180 |

| Third section | m/° (length/rotation) | 4.65/0-180 |

| Fourth section | m/° (length/rotation) | 4.05/0-180 |

| Platform rotation | ° | 360 |

| Boom Horizontal Length/Depth | m | 19.73/23 |

| Hydraulic System Pressure | MPa | 20 |

Boom Pressure Concrete Pump Compared With Other Concrete Pumps

| Type | Boom Pressure Concrete Pump | Stationary Concrete Pump | Truck Mounted Concrete Pump |

| Characteristics | Integrates multiple boom sections and high-pressure pumping system, allowing for remote control of high-rise buildings | Without boom frame and requires manual pipe laying | Installed on the truck chassis, with some extendable arms, but the conveying height is limited. |

| Usage Scenarios | Large bridges and complex terrains | Suitable for ground or low to medium level transportation on roads, villas and small construction sites | Middle level buildings and road construction |

| Advantages and Disadvantages | High conveying efficiency, easy operation and wide applicability | The cost is low, but the efficiency is low and the requirement of labor is large. | flexible and maneuverable, but the coverage area of the boom is small |

Technical Advantages And Performance Highlights

In complex and ever-changing construction environments, it is crucial to choose a high-performance and flexible concrete pumping equipment. Boom pressure concrete pump is gradually becoming the preferred choice for construction units worldwide due to its leading technological configuration and excellent operational performance. Here are three core advantages that distinguish it from traditional pumping equipment.

High-lift and High-pressure Pumping Capacity

The requirements for concrete conveying height and pressure in modern engineering are becoming increasingly high. Boom pressure concrete pump adopts advanced hydraulic system with powerful output power, which can easily cope with vertical conveying tasks of tens of even hundreds of meters.

Suitable for high difficulty projects such as tall buildings, bridges, tunnels, etc. It is currently widely recognized as a high pressure concrete pump for tall buildings in the market.

In practical engineering and mainstream products, the maximum pumping pressure of boom pressure concrete pumps is usually:

| Types Of Boom Pumps | Boom Length | Range of Pumping Pressure |

| Small and medium-sized Boom Pump | 30m-40m | 8-16 MPa generally |

| Large Boom Pump | Over 50m | Round 20-30MPa |

| Ultra-high-rise pumping or special pump system | In extreme cases, customized pump systems may be used | Approaching 40MPa, extremely rare |

Multi Section Boom Frame, Flexible Control, Full Coverage

The boom system is one of the biggest advantages of boom pressure pumps. Usually equipped with 4-6 arms, the flexible and versatile folding design allows it to operate freely in narrow construction sites.

The high-precision hydraulic control arm can achieve 360° no dead angle pouring.

Compared to manual pipe layout or ordinary vehicle mounted pumps, the pumping process is more time-saving and labor-saving.

Especially suitable for working conditions such as bridge decks, foundations, large-scale slab casting, and urban intensive construction.

Users can choose the remote control boom pump function, which allows one person to remotely operate and complete the arm deployment, position adjustment, and fabric work, greatly improving the convenience and safety of construction.

Precise Control, Low Waste, And High Construction Quality

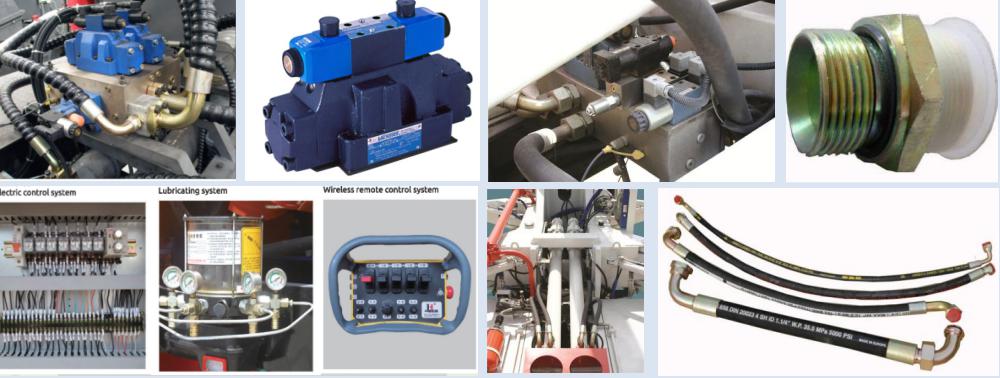

The precision requirements for concrete pouring in modern construction sites are becoming increasingly high. The boom pressure concrete pump is equipped with an intelligent distribution valve and a stable pumping system, ensuring that the concrete is evenly and continuously delivered to its intended location.

Automatic energy-saving reversing system reduces energy consumption.

Stable transportation, reduced rebound rate, and avoidance of secondary pollution and material waste during the pouring process.

The precision of concrete discharge is high, effectively improving the structural strength and appearance quality.

Mobility

As a truck mounted concrete pump, the equipment is integrated into the truck chassis, providing flexible transitions and adapting to continuous operations on multiple construction sites.

Smart Features

Equipped with pressure monitoring, intelligent warning, GPS positioning, remote fault diagnosis and other functions.

Easy Maintenance

The pumping system, pipelines, and hydraulic system are all designed modularly for easy daily maintenance and upkeep.

In short, the boom pressure concrete pump is not only a representative of high-pressure concrete pumping, but also fully meets the comprehensive needs of modern engineering for efficiency, safety and quality with its flexible arm, intelligent operation and precise construction.

Application Scenarios And Successful Cases

With the continuous expansion of urban construction scale, boom pressure concrete pumps are widely used in various complex working conditions, including high-rise buildings, bridges, highways, subway tunnels, and urban infrastructure projects. Its efficient pumping capability and flexible placing advantages have significantly improved on-site construction efficiency and concrete pouring quality.

Here are several representative application scenarios that you can present in the form of images:

Boom Pressure Concrete Pump For High Rise Projects

Efficient application of 63m Boom Pressure Concrete Pump in a high rise commercial and residential project:

High rise concrete pumping, urban skyline with boom pump

Concrete Boom Pump For Bridge Construction

A high-speed bridge project uses a 52m boom pump to improve the efficiency of bridge pier construction by more than 30%.

Concrete boom pump working on a highway bridge

Efficient Concrete Pumping For Urban Tunnel Work

The 37m boogm pump of LUTON achieves precise placing distribution and reduces labor costs in the Chengdu Metro project

Boom pump inside tunnel or urban metro construction site

Comparison Of Technical Parameter And Specifications

In order to meet different construction needs, LUTON GROUP offers various models with boom lengths ranging from 14m to 63m. The following is a list f core parameters and a comparison with mainstream products in the construction industry.

| Brand | Boom Length | Pumping Pressure | Delivery Capacity | Applications |

| PUTZMEISTER | 38m – 56m | 25MPa | 70 – 185 m³/h | high-end engineering and special construction |

| SCHWING | 28m – 52m | 13 -22 MPa | 60 – 160 m³/h | commercial residential and conventional construction sites |

| SANY | 38m – 62m | 25MPa | 80 – 170 m³/h | medium and large scale projects, multi story projects |

| LUTON | 14m – 63m | 7 – 20 MPa | 60 – 180 m³/h | high-rise buildings, bridges, tunnels |

The LUTON boom pressure concrete pump has excellent cost-effectiveness in terms of boom length coverage, pumping capacity and flexibility, making it an ideal choice for the mid-range market.

Why Choose LUTON GROUP

As a manufacturer with over30 years of experience in the field of concrete pumping equipment, LUTON GROUP has always focused on technological innovation and product quality, continuously improving product adaptability and customer satisfaction.

Our goal is to create equipment solutions for customers with higher construction efficiency and lower operating costs.

100+

Strong Guarantee

Our products are exported to more than 100 countries in Southeast Asia, the Middle East, South America, etc., winning widespread trust.

100%

Full Service

LUTON GROUP provides installation training, regular maintenance reminders, and fast delivery of global accessories

One-stop

One-stop Service

In addition to boom pressure concrete pump, it can also be matched with product series such as concrete mixing plants, trailer pumps and vehicle mounted pumps

If you are looking for a concrete conveying equipment that can handle high-pressure pumping and has precise boom frame material distribution capabilities, the LUTON boom pressure concrete pump will be your reliable choice. We provide matching models for different working conditions and are equipped with comprehensive after-sales support to help your deliver your project on schedule and complete it with high quality.

Or Immediately contact a professional engineering consultant to obtain customized recommendations and technical information.

How Does LUTON Boom Pressure Concrete Pump Work

Simply put, the boom pressure concrete pump utilizes a hydraulic system to drive the reciprocating motion of a piston, continuously drawing concrete from a hopper and delivering it to a pipeline system. Combined with a boom, the concrete is precisely delivered to the construction site through the pump pipe, enabling continuous, high-lift pumping over long distances.

The operating principle of a boom pump truck can be divided into five core parts: power transmission, pumping system, boom movement, hydraulic control, and electrical coordination. These systems work together to achieve efficient concrete delivery and precise distribution. The details are as follows:

Power Transmission – Switching Between Driving And Pumping

Chassis Power Source

The configuration of boom pump truck chassis is diverse, usually using international brands such as Mercedes Benz and Volvo, as well as various first tier brands from China. It can be optionally selected by customers. The pump truck is equipped with a high-power engine and a transfer case. When driving, the engine power is transmitted to the transfer case through the transmission shaft, driving the rear axle to move the vehicle.

Pump State Switching

When the operator turns the rocker switch to the pumping position, the cylinder pushes the shift fork to move, the cylinder pushes the shift fork to move, and the clutch sleeve connects the input shaft with the idler gear. Power is divided through the gear transmission chain (two axis gear → three axis gear → three axis):

Three axis right end: directly dives the boom arm pump to work, providing hydraulic power for the boom arm system.

Left end of three-axis: drives the main oil pump to work, providing hydraulic power for the pumping system.

Through the action of the cylinder, the boom pump truck can quickly switch between driving and pumping states.

Pumping System – Suction and Pressure Delivery Of Concrete

Hydraulic Drive

The pumping system is driven by an electric motor or diesel engine, and constant power control is achieved through a hydraulic system to automatically adjust the delivery volume. When hydraulic oil enters the main cylinder, the piston rod extends and retracts the other piston rod through a sealed circuit.

Concrete Conveying Process

- Inhalation Stage

When the piston rod of the main oil cylinder retracts, self suction occurs in the conveying cylinder. The concrete in the hopper is sucked into the conveying cylinder through the sliding valve suction port under atmospheric pressure and the assistance of the mixing blades.

- Pressure Delivery Stage

The other main oil cylinder pushed the piston rod to extend and press out the concrete in the conveying cylinder. Concrete enters the conveying port and Y-shaped pipe, and is finally discharged through the flexible hose at the end of the boom.

- Loop Back And Forth

The system automatically changes direction, allowing the pressure oil to alternately enter the main cylinder and complete continuous suction.

Boom Frame System – Collaborative Movement Of Multiple Arms

Boom Frame Structure

The boom is composed of 3 to 5 high-strength steel plates which are bent and nested together, connected by links, pins and hinges. They can be bent into R, Z or composite shapes to adapt to different construction scenarios. Each arm is equipped with an independent hydraulic cylinder to control its extension, folding and angle adjustment.

Principle Of Motion

- Rotation

The hydraulic motor drives the gears on the rotating table, driving the boom to rotate 360° around the base.

- Expansion And Folding

The hydraulic cylinder drives the piston to reciprocate, achieving the deployment and retraction of the arm. For example, a rubber hose is connected to the end of the four section boom to prevent concrete segregation.

- Load Analysis

The boom needs to bear its own weight, concrete weight, and wind load. Taking a 5-section arm pump truck as an example the weight of concrete in the end hose can reach 92kg, which needs to be precisely controlled by a hydraulic system.

Hydraulic System – Power Transmission And Control

Pumping Hydraulic System

To provide power for concrete transportation, the suction and pressure delivery of concrete are achieved through the reciprocating motion of the main oil cylinder.

Arm Hydraulic System

Control the extension, rotation, and folding of the boom. Adopting a balanced valve design even if the multi way valve oil supply is interrupted or the oil pipe breaks, the boom cylinder can still work independently to ensure safety.

Hydraulic Cylinder

The piston type hydraulic cylinder achieves reciprocating motion of the piston rod through a sealed design with and without rod chambers. For example, the arm mounted oil pump of the Rexroth pump truck adopts an axial piston pump design, with the plunger and plunger hole highly precisely matched, bringing excellent volumetric efficiency.

Electrical System – Intelligent Coordination And Remote Monitoring

Remote Control And Sensors

The operator controls the arm movement through the remote control, and the sensor monitors the real-time status of the pump truck (such as the angle of leg deployment, arm position, etc.) to ensure safe operation.

PLC Controller

Process sensors information and issue commands, coordinate the work of various systems. For example, when the legs are not fully extended, the PLC controller will limit the arm movement to prevent tipping.

Remote Monitoring

Through the GPRS/GPS system, the status of the boom pressure pump can be transmitted in real-time to the control center, enabling remote fault diagnosis and scheduling management.

Hot Models Of LUTON Concrete Pump

Mini Concrete Pump

High-Pressure Concrete Pump

Concrete Trailer Pump

Concrete Mixer Pump

Concrete Boom Pump