63 Meter Concrete Pump

Working on a construction project requires maneuverability? A 63-meter concrete pump with a Z-fold boom is an excellent solution!

Luton’s long boom concrete pump has longer-lasting, greater performance, and durable components, withstand extreme tests!

Lightweight design

Easy operation

Reach out to us to get a free quote!

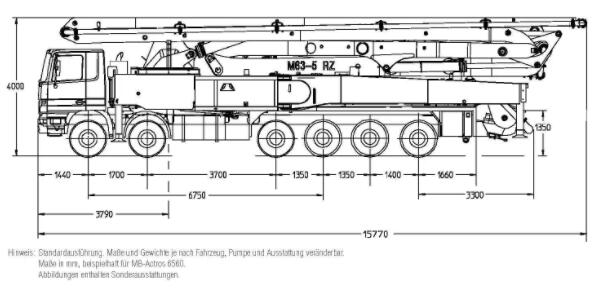

63 Meter Concrete Pump Specifications

Check for 63-meter truck-mounted concrete boom pump standard specifications:

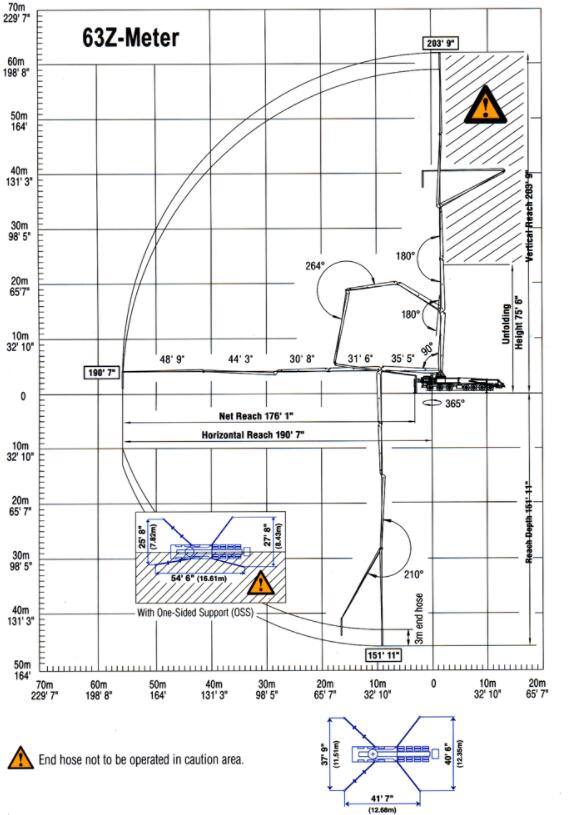

Boom specification

| Vertical Reach | 62.10 m |

| Horizontal Reach | 58.9 m |

| Reach from front of the Truck | 53.82m |

| Unfolding Height | 23.01 m |

Pump specification

| Max. Theoretical Output | 160 m3/h |

| Max. Pumping Pressure | 85 bar |

| Stroke Length | 2100 mm |

| Hydraulic System Pressure | 350 ba |

General specification

| Wheelbase | 7,112 mm |

| Front-axle Weight | 24,897kg |

| Rear-axle Weight | 33,429 kg |

| Water Tank | 780 L |

63 Meter Concrete Pump Truck at Worksite

Luton 63 meter concrete boom pump is placing concrete.

Luton long boom pump for foundation building.

Advantages of 63 Meter Concrete Pump

- The utilization rate of the arms rack pump is very high. That is to say, the equipment produces a large power, mixing speed and vey high pumping speed.

- Pump truck has a long placing boom, combine pumping, placing, and driving in one. It is very convenient with high pumping speed, to promote work efficiency.

- It saves taking-over time, reduces the pipe blocking rate. Remember when unfolding the pump boom, the operator should adhere to the instruction. Safety precautions should be strictly implemented.

- The pump outrigger is specially designed in order to adapt to the narrow field, and the mixing day pump is specially designed to expand their outriggers after a small area, but the stability of the whole machine has not been affected.

- Especially for short-distance pumping, the pumping cost is low and more economical, and energy-saving, which effectively avoids the useless power consumption and the movement cost caused by their own self-weight in long distance pumping.

- It is intelligent and convenient, concrete mixing pump truck generally adopts an intelligent boom system, which can be easily controlled with one key, and realize vertical or horizontal automatic pouring.

Long Boom Pump Truck V.S. Truck Mounted Line Pump

There are two types concrete pump options for construction: concrete boom pump and concrete line pump. So what are the differences between them and which one should you choose?

Compared with the concrete ground pump, the boom pump has its own placing boom. It does not need extra pipelines that can deliver concrete, saving time on installing them.

In addition, the truck boom pump is equipped with a car chassis, it can move independently and conveniently, and can quickly move from one construction site to another position.

Construction engineering is used for concrete pouring and tamping, such as high-rise buildings which need excellent maneuverability, truck boom pump is a better choice.

The use of a concrete line pump in many large basements is necessary and frequently and since it has no place boom, and manual takeover is required when use.

In addition, on the construction site, that high-rise pump is difficult to reach, and narrow space, such as 200 meters or 200 meters above, the ground pump to transport concrete is a good choice since it cab extend pipelines.

If the ground pump has enough power to hit the concrete to the above height, and the take-over length can reach the height of the built floor.

How to Operate Long Boom Pump Truck Safely?

The most common safety accident of pump truck all-in-one machine is a boom contacting with high-voltage line, broken boom frame, pump truck on fire, traffic rules breaking, and maintenance problems, and so on.

Operation tips:

- Park the pump in the working area. Pull the hand brake and shift the gear to neutral. Then get off the truck to observe whether the pump is on solid ground, and park the pump within the working range of the pump arm rack.

- After observing the terrain, switch the service switch on the operation panel of the electric control box to the pump position, start the chassis engine, and hang the chassis gear to 6.

- Then check whether emergency stop switches are open (There are 5 designed emergency stop switches)

- Deploy outriggers. Switch the outrigger switch and expand the six pump legs in turn. When setting up the outriggers, remember to put the wood block under the legs.

- The support plate or auxiliary square wood must be used to increase the support surface area and maintain the balance of the whole vehicle.

Precaution to keep in mind:

- When the pump truck is working, people is prohibited to stand under the placing boom rack.

- When remote control fails, do not push the operating handle back and forth, press the emergency button “emergency stop”

- The operator must not use the pump truck placing boom as a crane to lift heavy objects, especially the mixing pump truck. Cases have been found to have the illegal operation of the customer crane mixer.

- Regularly changes the boom pump pipe to avoid the concrete explosion caused by the pump pipe burst.

- Press the “emergency stop button” directly in an emergency without any other operations

Our partners

Our Certificates and Honors

Get A Free Quote

Mobile:

0086-173-2016-6678

Whatsapp:

0086-173-2016-6678

Email:

sales@ltconcretepump.com