JBS40 concrete mixer pump, as one of the most famous models of LUTON concrete mixer with pump equipment, is popular with customers around the world. Featured as efficient pumping capacity, portable structure and durable product quality, this kind of equipment combines multiple functions in one set, realizing a whole continuous process of concrete producing and conveying.

Years by years, LUTON engineers have extensively investigated various construction requirements and actual application feedbacks from customers all over the world. They have continuously optimized and updated the products, aiming to produce various concrete pumping products that meet the actual needs of customers. And JBS40 is one of the outstanding representatives among these products.

High Efficiency & Stable Performance

Powerful Pumping Capacity

Fully Intelligent Automatic Control System

Widely Exported To 100+ Countries

Thoughtful Sales Service Supplying 24h/7d

Long Service Life And Low Cost

Why Choose LUTON JBS40 Concrete Mixer Pump

Good sales reputation comes from excellent product quality. Concrete mixer with pumps are common concrete raw material conveying equipment in the modern construction industry. LUTON GROUP is a well-known concrete mixing pump manufacturer. For many years, LUTON’s mixing pump products have been active in the international construction equipment field and have been widely recognized and trusted by users around the world. Where does the good reputation come from? Let’s reveal it one by one.

Powerful Driving And High Efficiency

The LUTON mixer pump machine JBS40 prodcuts are designed with two power source models, diesel and electric. A variety of high-performance diesel power brands provide reliable energy and power. Customers can choose the pump power mode that suits them according to their actual needs.

For areas with abundant and stable electricity, customers can also choose electric models with simple structure and more convenient maintenance.

Whether it is diesel or electric, LUTON mixer pumps can easily cope with high-rise and long-distance concrete transportation tasks under strong and reliable power drive, greatly improving construction efficiency.

Multiple Mixing Methods Are Available

In order to meet customers’ different requirements for concrete mixing methods and quality, LUTON concrete mixing pump JBS40 can be equipped with a variety of mixer models, including drum mixers, twin-horizontal shaft mixers, planetary vertical shaft mixers, etc.

Drum Mixing Tank Mixer

Among them, the mixing tank mixer has a simple structure, low cost, easy operation and maintenance. It is suitable for a various bulk materials mixing. It is an economical choice and suitable for small projects with limited budgets ro scenarios with low requirements for mixing quality.

| Model | JBS40-10-84R |

| Max. theo. concrete output | 40 m³/h |

| Mixer rated feed capacity | 0.56 m³ |

| Max. concrete pumping pressure | 10MPa |

| Distribution valve type | S Valve |

| Diesel engine model | Weichai Deutz WP4G110E220 |

| Hydraulic circuit type | Open circuit |

| Theoretical Conveying Distance | 120/500 m |

Twin-shaft Mixer

Meanwhile, the twin-horizontal shaft mixer has high mixing performance, wide application range, high production efficiency, strong reliability and stability. This kind of mixer is suitable for mixing materials of various properties and proporties for the tasks of a large number of materials in large-scale continuous production.

| Items | JBS40B-JS750 |

| Main oil pump | Kawasaki, Korea |

| Main oil pump discharge | 112(ml/r) |

| Main Engine | 45 kw |

| Power of agitating motor | 30kw |

| Mixer productivity | 35 |

| Lubricating system | Automatic |

| Piping (m) | 100 m Φ125 |

Planetary Vertical-shaft Mixer

Planetary vertical shaft mixer can achieve extremely high mixing uniformity. Successfully handling various high viscosity and high consistency material mixing tasks, this kind of mixer machine has excellent mixing efficiency, good sealing performance, reduces material waste while ensuring a clean and safe working environment. It is particularly suitable for occasions with extremely high requirements for mixing quality.

| Items | JW40D-1000R |

| Max. theo. output | 50m3/h |

| Mixer Feeding Capacity | 1600L |

| Mixer Discharge Capacity | 1000L |

| Max.concrete pumping pressure | 129 WEICHAI DEUTZ or 132KW CUMMINS |

| Pumping system pressure | 28Mpa |

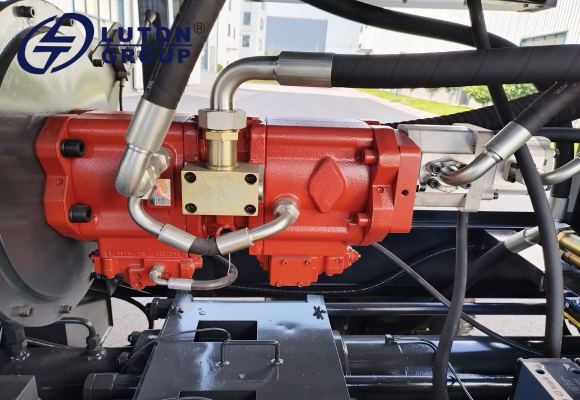

Simple And Practical Open-type Hydraulic System

LUTON pump and mixer machine products all adopt a kind of simple, convenient and practical open-circuit hydraulic transmission system. Equipped with a world-class plunger main oil pump, it can provide powerful driving energy for our pumps and easily meet the needs of high-load operations.

Fully Functional Automatic Control Unit

The LUTON concrete mixing pump machine uses PLC control technology from Omron to automatically control the entire production process of the whole machine, including mixing start/stop control and speed adjustment, pumping pressure and flow adjustment, and various fault protection. The control interface is simple and intuitive, easy to operate, which displays the equipment operating parameters in real time, also detects and alarm faults in time.

Combination Of High-quality Steel Structure And Portable Design

In order to make the mixing pump equipment more convenient to move and use at the construction site, LUTON engineers concentrated the entire pumping product on a trailer with wheels. The frame steel structure adopts high-strength steel structure, which is strong and durable and has a longer service life.

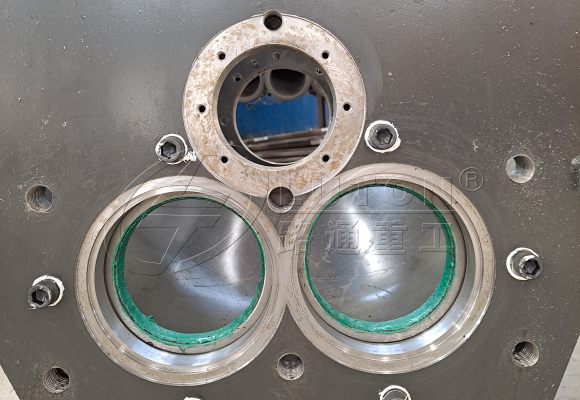

In the mixing system, the mixing blades are made of high-wear-resistant and high-strength steel materials; in the pumping system, the key wearing parts of the eyeglass plate and the cutting ring are made of high-strength and high-wear-resistant manganese steel alloy materials, which have a longer service life.

Reliable LUTON GROUP

- LUTON provides with professional technical services for the entire process of ” purchas-installation-debugging-use”, in every 24h/7days working cycle.

- LUTON offers you the most efficient product delivery service, from signing the order to completing production, it only takes 7-14 working days.

- With all offshore services, LUTON help customers receive the equipment faster and safer, to successfuly put it into construction projects.

- LUTON has always been working hard to provide high-quality products and service for customers all over the world!

Hot Models Of LUTON Products

Mini Concrete Pump

High-Pressure Concrete Pump

Concrete Trailer Pump

Concrete Mixer Pump

Concrete Boom Pump