Concrete pump hopper, also called as concrete bucket or concrete chut of a concrete pump machine, is an irreplacable component of the whole concrete pump system. It plays a crucial role in deliverying concrete to needed place on site.

This article shows you the concrete hopper commonly used in hot-selling LUTON concrete pump products. Know this important concrete pump component together!

What Is A Hopper On A Concrete Pump

Concrete pump hopper is a multi-functional container on concrete pumping equipment. It is the temporary storaging and mixing place before concrete pumped. Located at the rear of the concrete pump usually, it is connected with the pipeline and concrete cylinder, so the concrete hopper is also an important interface for the pump machine sucking and conveying concrete.

Concrete pump hopper is widely used in varioius concrete pump equipment, like concrete line pump, concrete mixer pump, truck-mounted concrete pump and concrete boom pump truck, etc. According to different types of pumps, requirements of pumping jobs, concrete pump hoppers are available in various sizes and configurations.

What Is Concrete Pump Hopper Used For

Concrete pump hopper, as we all know, is designed for three main functions:

1.Store a certain amount of concrete

2.Provide sufficient concrete for the pumping system to prevent the pump body from inhaling air during suction.

3.Implement the continuous pumping of the whole system

4.Stir the concrete materials for the second time to prevent concrete segregation and improve the pumping ability of concrete.

What Is A Good Concrete Hopper Structure For A Concrete Pump

A good concrete hopper is a safe place for temporary storage of concret pump, an important inlet and outlet of concrete raw materials. So, its structure should be strong enough to wear resistance, the mixing performance should be stable enough, S valve change should be smooth enough and the continuous pumping should be smooth.

- The stiffness and strength of hopper structure, especially of high pressure concrete pump hopper, should ensure that in the implementation of high-rise or high pressure conveying operation, no deformation, to avoide large pressure loss, short life of vulnerable parts.

- Structural design inside the hopper. The design of hopper internal structure is directly related to the pumping efficiency, and also affects the swing pressure loss of S valve. Good design ensures good suction pumping performance, to avoid the occurrence of material accumulation, pumping difficulties, cleaning difficulties and other phenomena.

What Is Concrete Pump Hopper Consisted Of

The concrete pump hopper is mainly composed of the following parts: hopper steel structure, mixing shaft, hydraulic motor, spectacle-plate, cutting ring, s valve, hydraulic swinging system, discharge port, screen and vibrators, etc.. Some pump products also add manual or automatic cleaning system for the hopppers.

Hopper Steel Structure

The hopper is the place of holding and discharging concrete materials, so its main structure must be strong and durable.

Concrete hopper in LUTON concrete pump products are made of carbon manganese steel material, plus three layers of spray paint process, it is more water-, moisture- and rust-proof, strong and wear-resistant.

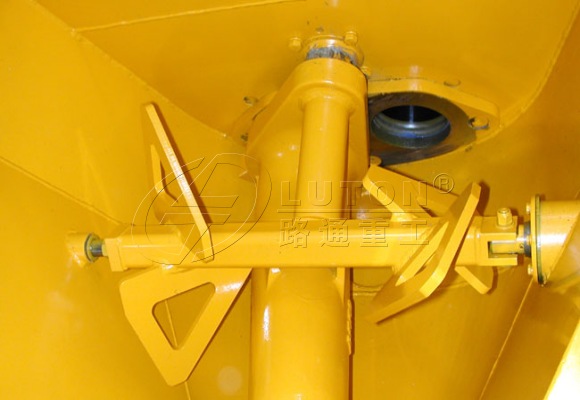

Mixing Shaft

The mixing shaft fixed inside the concrete hopper is mainly composed of mixing shaft, spiral mixing blades and shaft sleeve. The screw mixing blades are welded on the mixing shaft, mainly used for mixing temporarily stored the concrete, on the one hand to make the material uniform and easy to transport, on the one hand to prevent concrete segregation.

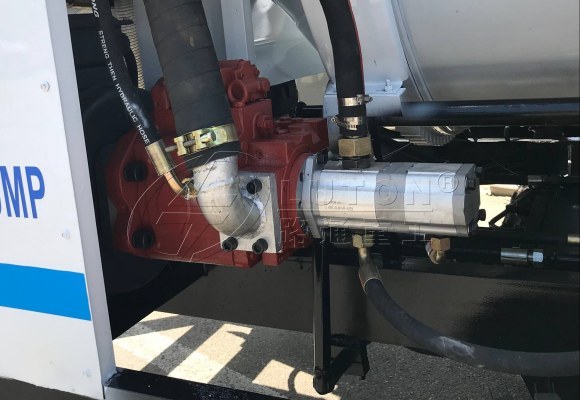

Hydraulic Motor

The hydraulic motor is usually installed on the outer side of the hopper, and is the power unit of the mixing shaft. The energy source comes from the hydraulic oil pump and gear pump inside the pump body.

Discharge Port

Discharge port is designed at the rear of the hopper, which directly connect with the conveying pipeline.

When connecting with the conveying pipe, straight pipes and elbow pipes can be installed according to the actual field environment and conveying requirement. Then, use the pipe clamps to reinforce the connection.

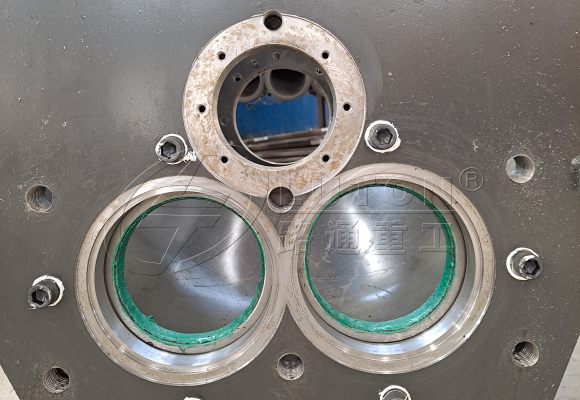

Spectacle Plate and Cutting Ring

Spectacle plate and cutting ring are both important accessories in concrete pumping equipment. Their state directly affects the workiing stability and service life of concrete pump machinery, and they are also the vulnerable parts during the process of concrete pumping.

Among them, spectacle plate also called wear resistant plate, whose name is from its two holes shape just like a pair of spectacle. Cutting ring is also called wear-resistentt ring, whose name is from its shearing movement working method.

During pumping, the spectacle plate and cutting ring, mounted in the wall of the concrete hopper, cooperate with the rubber spring, compensating the gap between the cutting ring and the spectacle plate by pressure sefl-balancing. No matter which port the hydraulic cylinder connects, the S valve to the spectacle plate can always ensure a sealing effect. Thus, increasing the transmission pressure of the S pipe valve in this way.

Every time the S distribution valve swings, the cutting ring is rubbed with the glasses plate. Also there is the friction of stones and sand in the concrete, so the impact and friction of the cutting ring and the glasses plate are very large. In order to extend the service life of the spectacle plate and cutting ring, hard alloy material is commonly used.

Screen and Vibrator

S Valve and Swing Cylinder

Spectacle plate and cutting ring are both important accessories in concrete pumping equipment. Their state directly affects the workiing stability and service life of concrete pump machinery, and they are also the vulnerable parts ing the process of concrete pumping.

Among them, spectacle plate also called wear resistant plate, whose name is from its two holes shape just like a pair of spectacle. Cutting ring is also called wear-resistentt ring, whose name is from its shearing movement working method.

During pumping, the spectacle plate and cutting ring, mounted in the wall of the concrete hopper, cooperate with the rubber spring, compensating the gap between the cutting ring and the spectacle plate by pressure sefl-balancing. No matter which port the hydraulic cylinder connects, the S valve to the spectacle plate can always ensure a sealing effect. Thus, increasing the transmission pressure of the S pipe valve in this way.

Every time the S valve swings, the cutting ring is rubbed with the glasses plate. Also there is the friction of stones and sand in the concrete, so the impact and friction of the cutting ring and the glasses plate are very large. In order to extend the service life of the spectacle plate and cutting ring, hard alloy material is commonly used.

The Screen covering on the concrete hopper is used to filter the materials that do not meet the pumping requirements.

The screen covering on the concrete hopper is used to prevent the oversized aggregate or other debris from entering into the concrete mixing material, reduce pumping faults and protect the safety of operators. The vibrator is designed for quick feeding concrete.

How To Maintain A Concrete Pump Hopper After Use

Concrete hopper is a very important part of concrete pump. The maintenance of concrete pump hopper not only affects the smooth progress of concrete pumping work, but also affects the service life of the pump. The following content are about several important points of maintaining the concrete pump hopper.

Clean Up After Pumping

After the concrete pumping is completed, the hopper should be cleaned in time to ensure that there is no material residue in the hopper, to prevent the wear of the lower part of the S pipe or even wear through the scrap. We must also open the hinge bend to clean the interior of the S valve to prevent the occurrence of pipe blocking phenomenon.

Cutting Ring Safety Inpection

When the concrete pump is not in use, attention should be paid to check the gap between the cutting ring and the spectacle plate every day to check whether the cutting ring is damaged. If it is found to be worn and only the wear strip in protects the carbide overweld, the cutting ring can be turned 90 degrees, which will extend the service life of the cutting. If the cutting ring is seriously won out, it should be replaced in time.

Inspection Of The Mixing Blades

The wear of the mixing blades will cause the poor suction performance of the pump machine. So it is necessary to check and replace the blades in time. If the mixing blades are to be welded, the distance between the blades and the wall of the hopper at any position should not be less than 5cm, otherwise the hopper will be worn through.

Inspection Of Overcovers And Observation Holes

The transition part between the concrete pump spectacle plate and the conveying cylinder is generally equipped with transition cover, and it should be checked frequently.

If the wear is serious and its height is lower than the conveying cylinder, the transition sleeve should be replaced in time, otherwise the life of the conveying cylinder will be greatly affected. It is strictly prohibited to wrap the mixing motor. It is recommended to check the observation hole of the mixing motor seat every day. Any slurry leakage should be handled in time.