Concrete piston pump is a kind of equipment that fulfills concrete conveying by reciprocating motion of the pistons. It utilizes the negative pressure and hydraulic pressure inside the sealed cylinder to suck in and discharge concrete. Combined with the collaborative work of other components, concrete piston pump achieves concrete pumping.

This type of pump has compact structure, strong pumping capacity, stable pumping pressure, high efficiency, as well as wide application range, etc.. It is suitable for concrete conveying tasks in various buildings, roads, bridges, and other engineering projects. Especially in the fields of high-rise buildings and underground engineering, it has obvious advantages.

Hot Models Of LUTON Concrete Piston Pumps

At present, piston pumping technology is widely used in various concrete pumping equipment. What’s more, concrete piston pumps are also one of the best-selling pump products of LUTON GROUP.

As a well-known enterprise in the global construction machinery field, LUTON GROUP has nearly 30 years of experience in manufacturing, exporting, and after-sales service. Since its establishment, LUTON has been providing global customers with concrete pumping equipment.

Hot Models Of LUTON Trailer Pumps

LUTON trailer concrete pumps are various according to different pumping capacities. The models of HBT30 and HBT40 are especially popular with customers.

| Items | HBT30-6-52R |

| Max.theo.concrete output (L/H) | 30m3/h |

| Max.concrete pumping pressure(L/H) | 6MPa |

| Distribution valve type | s |

| Concrete cylinder diameter×stroke | Ф200×500mm |

| Outlet diameter | Ф180mm |

| Diesel engine model | Yuchai |

| Electrical engineering power | 52KW |

| The biggest transportation(vertically/Level) | 100/300m |

| Items | HBT40-10-82R |

| Max.theo.concrete output (L/H) | 40m3/h |

| Max.concrete pumping pressure(L/H) | 10MPa |

| Distribution valve type | s |

| Concrete cylinder diameter×stroke | Φ180/1300mm |

| Outlet diameter | Ф150mm |

| Diesel engine model | Weichai |

| Engine power | 82KW |

| The biggest transportation(vertically/Level) | 120/500m |

Hot Models Of LUTON Mixer Pumps

LUTON concrete mixer pumps are also hot saled around the world.

| Items | JBS40-10-82R |

| Max.theo.concrete output | 40m3/h |

| Mixer rated discharge capacity | 0.45m3 |

| Max.concrete pumping pressure | 10MPa |

| Distribution valve type | S |

| Diesel engine model | 82KW Weichai Deutz WP4G110E220 |

| Max. Theoretical Conveying Distance (Vertical/Horizontal) | 120m/500m |

| Items | JBS40B-JS750 |

| Main oil pump | Kawasaki, Korea |

| Main oil pump discharge | 112(ml/r) |

| Main Engine | 45 kw |

| Power of agitating motor | 30kw |

| Mixer productivity | 35 |

| Lubricating system | Automatic |

| Piping (m) | 100 m Φ125 |

| Items | JW40D-1000R |

| Max. theo. output | 50m3/h |

| Mixer Feeding Capacity | 1600L |

| Mixer Discharge Capacity | 1000L |

| Max.concrete pumping pressure | 129 WEICHAI DEUTZ or 132KW CUMMINS |

| Pumping system pressure | 28Mpa |

The Advantages Of Concrete Piston Pumps

Compact Structure

The compact structure of concrete piston pump, taking up little space, is easy to arrange and operate on construction site.

Efficient Pump Capacity

With efficient pumping capacity, concrete piston pump can deliver concrete materials quickly and continuously to the required position onsite. It greatly shortens the construction time and improves working efficiency.

Long Pumping Distance

Concrete piston pump transports concrete through pipelines. So, it is competent for long-distance concrete conveying of high-rise buildings, bridges, tunnels and other construction projects.

Easy Operation

Concrete piston pump adopts automatic control system, which is simple and convenient to operate. The control system reduces the complexity of manual operation and labor intensity.

Good Stability

Concrete piston pump ensures stable pumping pressure and flow during transportation, avoiding problems such as layering and segregation, and ensuring the quality of concrete.

Energy Saving and Environmental Protection

Concrete piston pump adopts advanced energy-saving technology, with less energy consumption and lower emission, which meets the requirements of green construction.

Easy Maintenance

The structure design of concrete piston pump is reasonable. It is easy to maintain and quickly troubleshoot, reduce downtime, and improve equipment utilization.

Concrete piston pumps have many advantages, correct operation and maintenance are still should be noticed to ensure their normal operation and extend the service life. When selecting a concrete piston pump, comprehensive consideration should be given to specific engineering requirements, construction environment, and budget factors.

The Components of Concrete Piston Pumps

Pump Body

The pump body is the main part of a concrete piston pump. It is usually made of high-strength alloy steel. So, it is capable of withstanding high pressure and heavy loads. The pump body is equipped with concrete cylinders and hydraulic cylinders, which are the core components of concrete conveying. Usually, in order to cool the piston rod, there is also a cooling water tank between the two cylinders.

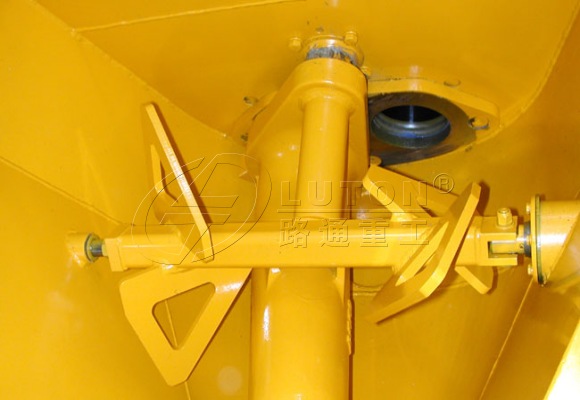

Piston

Pistons are ones of the core components of concrete piston pumps. They are made of high-strength alloy steel, with strong wear resistance and corrosion resistance. The piston moves back and forth in cylinders, sucking and discharging concrete by changing the volume of the concrete cylinder.

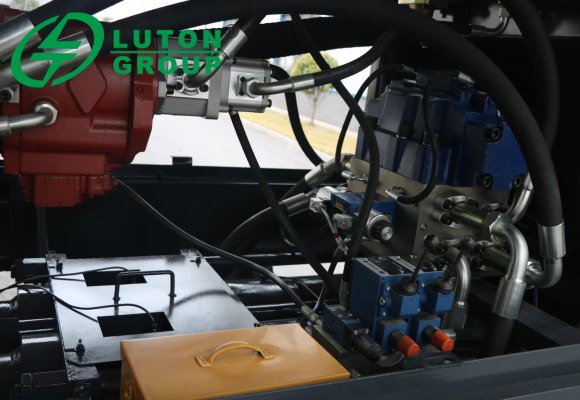

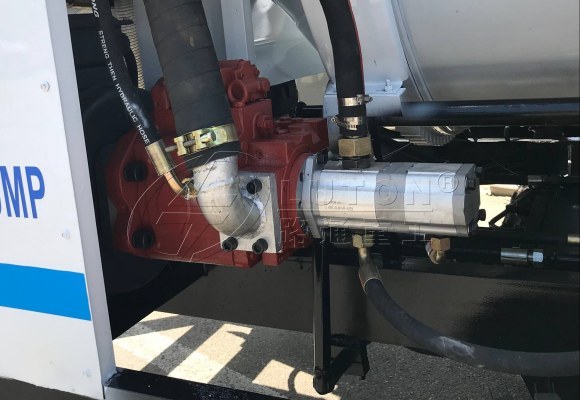

Hydraulic System

The hydraulic system is the power source of concrete piston pump, composed of oil tank, oil pump, hydraulic motor, control valve, etc. The hydraulic system provides power to the piston, allowing it to perform reciprocating motion within the concrete cylinder.

Conveying Pipeline

The pipelines are crucial parts that connects pump body and the pouring site. Usually they are made of high-strength steel pipes or rubber hoses. The conveying pipelines can transport concrete from the pump body to any designed pouring location.

Distribution Valve

Distribution valve is an important component in the concrete piston pump. Its duty is to control the suction and discharge of concrete. The distribution valve ensures that concrete smoothly enters into and leave the concrete cylinder. The distribution valves of LUTON pumping products are S valves.

Hopper

The hopper is the feeding port of a concrete piston pump, usually located above the pump body. The hopper can accommodate the pump body. The hopper can accommodate a certain amount of concrete, ensuring that the concrete continuously enters into the pump body.

Lubrication System

The lubrication system is used to lubricate the various components of the concrete piston pump. The aim is to ensure the normal operation of the equipment and extend its service life. The lubrication system usually consists of an oil pump, oil tank, pipelines, and lubrication points.

In addition, concrete piston pumps may also include other auxiliary components such as electrical control systems and safety protection devices to ensure the normal operation and operational safety of the equipment.

Working Principle Of Concrete Piston Pump

The working principle of a piston pump mainly involves the reciprocating motion of the piston in the pumping cylinder to generate concrete flow, which is similar to the working principle of a syringe.

The LUTON GROUP concrete piston pump combines the characteristics of the S-valve and the working principle of the piston pump to achieve continuous, stable, and efficient concrete pumping.

Inhalation Stage

When the concrete cylinder piston begins to move backwards, the volume inside the pump gradually increases, forming a negative pressure. At this point, the S valve (also known as the cutting valve or slide valve) is in the open state, allowing concrete to enter the concrete cylinder chamber of the pump body from the hopper or storage device through the S valve.

Discharge Stage

When the piston of the concrete cylinder moves forward, the volume inside the pumping cylinder decreases. In this way, the piston compress concrete out of the pumping cylinder and transport through the conveying pipeline to the definite place.

S-valve Control

In the material discharge stage, in order to achieve continuous concrete pumping effect, two sets of parallel arranged cylinder blocks alternate suction and pressure discharge actions. A series of control methods needed to coordinate the action sequence of all actuating components, including two sets of cylinder pistons and S-valves. The most common is the S-valve hydraulic control method. Connect the outlet of the concrete cylinder and the output port of the pump body with an S valve. Under the control of the hydraulic system solenoid valve block, coordinate the action time of the cylinder piston and S valve to achieve the final continuous output of concrete.

Hydraulic System Drive

To achieve this process of suction and discharge, we also need to push or pull back the piston and connecting rod through external forces, which come from the hydraulic power converted from the main force. In a closed hydraulic cylinder, high-pressure hydraulic oil continuously flows forward under the action of the control system, pushing the hydraulic piston to move backward until the hydraulic oil fills the entire hydraulic cylinder block. The piston moves to the end of the cylinder block, and the connected concrete cylinder piston completes the suction process.

On the contrary, when the hydraulic oil flows in the opposite direction, the piston moves from the end of the hydraulic cylinder to the front end, and the concrete cylinder piston connected to it moves forward, pumping all the concrete out of the cylinder. This pumping action is completed.

Concrete Pumps For Other Structures

From a structural perspective, in addition to concrete piston pumps, there are also compression type concrete pumps, water pressure diaphragm type concrete pumps, etc.

Squeeze Concrete Pump

There are various types of squeeze concrete pumps, such as rotor type double roller type, straight pipe type three roller type, and belt type double groove type. They mainly push concrete and achieve transportation by squeezing rubber hoses or related components.

Water Pressure Diaphragm Concrete Pump

This type of pump mainly consists of a hopper, pump body, diaphragm, control valve, water pump, and water tank. It utilizes the synergistic effect of water pressure and diaphragm to push concrete to the target location.

Each type of concrete pump has its specific advantages and applicable scenarios. Therefore, when selecting a concrete pump, it is necessary to comprehensively consider factors such as specific engineering requirements, construction environment, and budget. At the same time, attention should also be paid to selecting pump types with reliable quality and stable performance to ensure efficient and safe construction.

Mini Concrete Pump

High-Pressure Concrete Pump

Concrete Trailer Pump

Concrete Mixer Pump

Concrete Boom Pump