When it comes to placing concrete, nothing beats the efficiency, reach, and precision of a concrete lorry pump. More than just a machine, this large mobile powerful pumping lorry is a strategic asset for any modern construction project. Know more about LUTON concrete lorry pumps – workflows, transformative benefits, and the key to selecting equipment that will drive your business forward.

Unparalleled Efficiency

Flexible Site-Adaptability

Superior Concrete Quality and Structural Integrity

Powerful Tool For Cost Reduction

What Is A Concrete Lorry Pump

At its core, a concrete lorry pump is a marvel of hydraulic and mechanical engineering. It is a fully integrated, truck-mounted concrete pumping system that combines mobility with immense power. The most visually striking component is the multi-section, articulating robotic arm, know as a “boom”, which is mounted onto a specially designed truck chassis.

But it’s more than just a truck with a long arm. The system consists of several key components working in perfect harmony.

Truck Chassis

The foundation, providing the mobility to move between sites quickly. These are often robust, multi-axle chassis designed to handle the immense weight and stress of the equipment and concrete load.

Boom and Pipelines

The boom, made of high-strength, low-alloy steel, can have three, four, or even five sections, allowing it to fold, extend, and articulate with remarkable precision. Steel or wear-resistent alloy pipelines are attached along the boom, with a flexible and hose allowing for final, precise placement.

Pumping Mechanism

Typically a dual-cylinder hydraulic system. While one cylinder draws liquid concrete from the hopper, the other pushes concrete into the delivery pipeline. A specially designed valve, known as an S-valve or Rock valve, switches between the cylinders to ensure a continuous, pulsation-free flow of concrete – a critical factor for high-quality finishes.

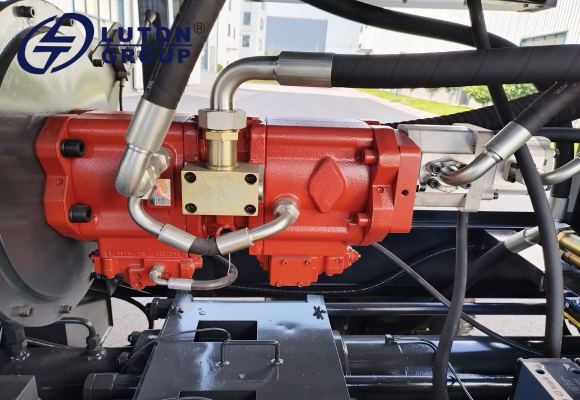

Hydraulic System

The heart of the concrete lorry pump. A powerful diesel engine drives hydraulic pumps that generate the fluid power needed to operate both the pumping cylinders and the boom’s intricate movements.

LUTON – Your Partner In Concrete Placement Excellent

Understanding the theory is the first step. The second, and most critical, is accessing equipment that delivers on these promises with unwavering reliability. At LUTON, we don’t just sell concrete lorry pumps. We engineer productivity solutions. Our philosophy is built on a foundation of robust design, innovative technology, and unparalleled customer support.

LUTON Concrete Boom Pump

| Model | 30m~61m |

| Max. theo. concrete output | 85-200 m³/h |

| Max.concrete pumping pressure | 8.7-10 MPa |

| Boom horizontal height | 25m-55.6m |

| Turnable Rotation Angle | ±210°/±360° |

| End flexible hose length | 3000mm |

| Boom outrigger | 4Z/5RZ/6RZ/7R |

| Min. expanded height | 7.1 ~ 14.9 m |

LUTON Small Concrete Boomp Truck

| Model | Unit | LTB40R-15/21 |

| Output capactiy | m³/h | 40/50 |

| Pumping pressure | Mpa | 10 |

| Distribution valve type | s valve | |

| Vertical height of boom | m | 15.4/22 |

| Diesel engine model | Weichai 82kW | |

| Max.aggregate diameter | mm | 30 |

Beyond The Boom – Distinguishing Between Concrete Pump Types

While this article focuses on the concrete lorry pump, it’s crucial to understand the broader landscape. Knowing the alternatives helps solidify why the truck-mounted boom pump is often the preferred choice for many applications.

Trailer Concrete Pump

These are separate, trailer-mounted pumping units without a built-in boom. They require a separate setup of rigid or flexible concrete placement lines that must be manually assembled and disassembled. Ideal for high-volume, long-distance horizontal pumping (e.g., basements, large slab-on-grade projects) where the reah of a boom is not required, and where the cost of manual piping is justified.

Line Pump Truck

A bigger, more portable version of a trailer pump, often on a common truck. It uses flexible hoses and is perfect for smaller jobs, residential projects, swimming pools, and sidewalks where access is tight and volumes are lower.

Advantage of Concrete Lorry Pump

The primary advantage of the concrete lorry pump is its integrated, rapidly deployable boom. It eliminated the need for time-consuming manual pipe setup, offering unparalleled speed and flexibility for projects with complex reach requirements.

The Compelling Advantages of Integrating Concrete Lorry Pump into the workflow

The decision to use a concrete pump truck is an investment that pays divedents across your project. The benefits extend far beyond simply moving concrete from point A to point B.

Revolutionizing Project Timelines and labor Efficiency

Imagine pouring a large foundation or an elevated slab in hours instead of days. A concrete lorry pump can achieve output rates of 100+ cubic meters per hour, dramatically accelerating project schedules. This efficiency translates directly to labor savings, requiring only a small crew at the point of placement compared to the large teams needed for wheelbarrow or crans.

Unlocking Various Pumping Possibilities

The articulating boom is a game-changer for complex designs. It can effortlessly navigate over obstacles, deep ito excavations, or up to the top floors of high-rises. This allows architects and engineers the freedom to design without being overly constrained by concrete placement limitations. It also solves access issues in tight urban sites where space for cranes and other equipment is nonexistent.

Achieving Superior Concrete Quality and Structural Integrity

The continuous pumping process minimizes the risk of “cold joints” – weak planes in the concrete that occur when a subsequent pour is made after the initial layer has already begun to set. The result is a more homogenous, denser, and stronger concrete structure. Furthermore, the controlled flow reduces segregation of the mix, ensuring a consistent aggregate distribution.

Creating a Inherently Safer Worksite

Safety is paramount. By mechanizing the placement process, a concrete lorry pump significantly reduces the number of workers needed in high-risk areas, such as on open formwork, at height, or in deep trenches. The operator can control the entire pour form a safe, distant vantage point using the wireless remote.

The Boom Line – A Powerful Tool For Cost Reduction

While the rental or operational cost of a pump is visible, the true savings are holistic. Reduced labor costs, shorter project durations (which lower overheads), less need for auxiliary equipment, and fewer potential delays due to weather or complexity all contribute to a healthier bottom line.

How to Choose the Perfect Model Of Concrete Lorry Pump

Calculate Reach and Output

Determine the maximum vertical and horizontal reach required, plus teh desired cubic yards per hour output.

Analyze Site Concrete Mix

Assess ground bearing capacity (for outriggers), overhead obstacles and space for truck maneuverability.

Understand Your Concrete Mix

Provide your mix design (slump, aggregate size and type) to the pump supplier to ensure compatibility.

Consider Project Timeline

For long-duration projects, reliability and service support become as important as raw specifications.

Partner with an Expert

Consult with a knowledgeable supplier like LUTON early in the planning process.

Essential Operation Rules of Concrete Lorry Pump

Always conduct a pre-operation inspection of the ground, the truck, and the boom.

Ensure the pump is set up on stable, compacted ground with all outriggers fully extended and on proper footing.

Never allow the boom to contact any object or be used to move the truck.

Establish clear communication protocols between the operators, the concrete truck drivers, and the placemetn crew.

Implement a rigorous pipeline cleaning procedure immediately after each pour to prevent setting and costly bolckages.

Elevate Your Projects with the Right Equipment and Partnership

A concrete lorry pump is a transformative tool, but its true potential is only unlocked when it is the right model, operated correctly, adn backed by a supplier you can trust. It represents a strategic decision to build smarter, faster, and safer.

By choosing LUTON, you are not just acquiring a machine. You are gaining a dedicated partner committed to your success. From the initial consultantion and model selection to on-site training and 24/7 service support, we are with you every step of the way.

Hot Models Of LUTON Concrete Pumps

Mini Concrete Pump

High-Pressure Concrete Pump

Concrete Trailer Pump

Concrete Mixer Pump

Concrete Boom Pump