A commercial concrete pump is a cornerstone of modern construction projects. Whether you are working on residential buildings, commercial complexes, or large infrastructure projects, a reliable concrete pump ensures that concrete is delivered quickly, accurately, and efficiently. From diesel and electric trailer pumps to mixer pumps, truck-mounted pumps, and boom pumps, these machines are designed to meet the diverse needs of contractors and builders, enhancing productivity while maintaining concrete quality.

Cost and Labor Saving

Versatility and Flexibility

Durability and Long Service Life

Adaptibility to Different Concrete Types

Easy Integration with Other Equipment

Tpyes of Commercial Concrete Pumps

Diesel and Electric Trailer Pumps

Trailer-mounted concrete pumps offer flexibility and mobility, suitable for medium-scale projects.

Diesel trailer pumps are ideal for remote or outdoor sites without electricity, while electric trailer pumps are cleaner and energy-efficient for urban or indoor projects.

Concrete Mixer Pumps

Concrete mixer pumps, available in both diesel and electric models, integrate concrete mixing and pumping in a single unit. They are perfect for on-site mixing, reducing labor and material segregation while improving workflow efficiency.

Truck-mounted Concrete Pumps

These high-capacity concrete pumps are mounted on trucks, providing easy relocation between sites. They deliver large volumes of concrete continuously, making them ideal for infrastructure projects and large-scale commercial developments.

Concrete Boom Pumps

Equipped with a long robotic arm, boom concrete pumps allow precise concrete placement for high-rise buildings, bridges, and hard-to-reach areas. They excel in both horizontal and vertical pumping, ensuring consistent quality.

Key Features and Advantages of Using a Commercial Concrete Pump

High Efficiency and Continuous Pumping – Smooth, continuous concrete flow for faster project completion.

Cost and Labor Savings – Reduces manpower and operational costs.

Versatility and Flexibility – Suitable for various project types and site conditions.

Durability and Long Service Life – Wear-resistant materials ensure reliable long-term performance.

Adaptibility to Different Concrete Types – Handles high-strength, lightweight, and pumpable mixes.

Precision and Quality – Accurate placement reduces materials waste.

Safety and Reliability – Advanced controls and safety features minimize on-site risks.

Easy Integration with Other Equipment – Compatible with mixers, hoppers, and pipelines for streamlines workflow. It can cooperate with concrete mixers, truck mixers, level machines and other equipment onsite to complete a line of workflow for continuous concrete construction.

How to Choose the Right Commercial Concrete Pump

Project Scale and Concrete Volume

Small to medium projects – Trailer-mounted concrete pumps or mixer pumps

Large-scale projects – Truck-mounted pumps or boom pumps for high output and continous placement.

Pumping Distance and Height

Long horIzontal distance: high-pressure trailer pumps or boom pumps.

High vertical placement: boom pumps and truck-mounted pumps with adequate pumping pressure.

Power Source and Site Conditions

Diesel pumps: remote or outdoor sites, high mobility

Electric pumps: urban or indoor projects, low noise, zero emissions.

Evaluate space, terrain, and accessible spare parts and technical support.

Maintenance and After-sales Support

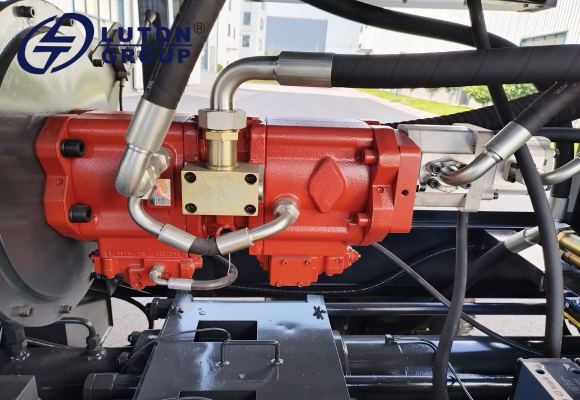

Check hydraulic systems, lubricate moving parts, and inspect wear components regularly.

Check hydraulic systems, lubricate moving parts, and inspect wear components regularly.

Opt for manufacturers offering accessible spare parts and technical support.

Budget and Total Cost of Ownership

Consider initial purchase price, operating costs, labor savings, and long-term durability.

Investing in high-quality pumps reduces downtime, improves efficiency, and provides better ROI.

FAQ – Common Questions About Commerical Concrete Pumps

How far can a commercial concrete pump deliver concrete?

It depends on pump type and pressure. Boom pumps and truck-mounted pumps deliver long distances and high elevations. Trailer pumps suit medium ranges.

What is the lifespan of a concrete pump machine?

With proper maintenance, a commercial concrete pump can last 10-1`5 years. High-quality diesel/electric trailer pumps, mixer pumps and boom pumps are built for long-term durability.

Can it handle lightweight or high-strength concrete?

Ordinary commercial concrete pumps can be used to pump lightweight concrete (aggregate pretreatment is required) under certain conditions.

However, due to the large differences in physical properties of high-strength concrete, it is recommended to use dedicated high-strength pumps or specially designed pumping systems.

What maintenance does it require?

Regular hydraulic checks, lubrication, and wear-part inspection. Pumps with strong after-sales support simplify maintenance and extend service life.

How to ensure safe concrete pumping on site?

- Stable, level setup and secure outriggers.

- Monitor pumping pressure and pipeline integrity.

- Train operators and use appropriate pump types (boom, trailer, truck-mounted).

Choose the Right Commercial Concrete Pump For Your Projects

A commercial concrete pump is essential for efficient, precise and reliable concrete placement. From diesel and electric trailer pumps to mixer pumps, truck-mounted pumps, and boom pumps, selecting the right machine based on project scale, pumping distance, site conditions, and concrete type ensures smooth operation and optimal results.

Investing in a high-quality pump reduces labor costs, improves project timelines, maintains concrete quality, and ensure safe operation. Contact our team to find the perfect commercial concrete pump solution for your construction projects.

Export Cases of LUTON Products

HBTS30 Concrete Pump Sold To Panama

HBTS40 Concrete Pump To Ethiopia

Concrete Pump In Pakistan

Concrete Pump Indonesia

Concrete Pumps In India

Concrete Trailer Pump For Sale Australia

HBT90 Diesel Concrete Trailer Pump To Armenia

Concrete Mixer Pump Exported To Sierra Leone

Concrete Mixer Pump Exported To Kenya

LUTON Concrete Trailer Pump To Brunei

Concrete Trailer Pump To Jamaica