Advanced concrete pumping refers to the use of modern, high-efficiency pumping systems to deliver concrete with greater speed, precision, height capacity, and safety compared to traditional methods. Instead of relying on manual labor or outdated equipment, advanced concrete pumping uses high-pressure pumps, intelligent control systems, and optimized pipelines to ensure stable concrete flow even in challenging conditions.

This technology is widely used in high-rise buildings, long-distance conveying projects, large-volume concrete pours, and applications requiring strict placement quality. Contractors adopt advanced pumping systems to reduce labor needs, accelerate construction schedules, and ensure consistent concrete quality on every jobsite.

Faster Placement & Lower Labor Cost

Extended Pumping Distance & Height

Smart Monitoring for Better Quality

Higher Safety Level & Flexibility

Key Technologies Behind Advanced Concrete Pumping

Modern advanced concrete pumping technology integrates multiple engineering innovations.

High-pressure Pumping Systems

High-pressure hydraulic systems allow concrete to be pumped over hundreds of meters vertically or horizontally, ensuring stable delivery even with stiff mixes or long pipeline layouts.

Smart Pumping Control

Advanced pumps use closed-loop control, real-time sensors, pressure feedback, and anti-pulsation technology to ensure smooth, continuous concrete flow.

Boom Precision & Anti-Vibration Technology

On boom pumps, modern anti-sway systems increase boom precision, improving concrete placing accuracy and jobsite safety.

Wear-resistant Materials & Optimized Pipe Design

Advanced delivery pipes, S-tubes, and wear plates extend the service life of the system and reduce maintenance downtime.

Telematica & Remote Monitoring

Many advanced concrete pumps offer BDS or GPS tracking, machine diagnostics, performance monitoring, and remote support – ideal for fleet management.

Advantages of Advanced Concrete Pumping

The construction industry increasingly prefers advanced concrete pumping because it offers significant performance and economic benefits:

Faster placement speed with consistent output

Lower labor costs due to automation and controlled operation

Extended pumping distance and height, ideal for high-rise buildings

Less segregation and improved concrete consistency

Better quality control through smart monitoring systems

Higher safety level on congested or complex job sites

Capability to handle demanding structures, tunnels, or large foundations

For contractors, these advantages translate into measurable gains in project efficiency and profitability.

Types of Advanced Concrete Pumping Equipment

A wide range of advanced concrete pumping equipment is used in modern construction.

Advanced Boom Pump

Truck-mounted boom pumps equipped with intelligent control, hydraulic stabilization, and high-efficiency placing booms.

| Model | 30m~61m |

| Max. theo. concrete output | 85-200 m³/h |

| Max.concrete pumping pressure | 8.7-10 MPa |

| Boom horizontal height | 25m-55.6m |

| Turnable Rotation Angle | ±210°/±360° |

| End flexible hose length | 3000mm |

| Boom outrigger | 4Z/5RZ/6RZ/7R |

| Min. expanded height | 7.1 ~ 14.9 m |

High-pressure Line Pump

High-pressure line pump is ideal for long-distance horizontal or vertical pumping, especially for high-rise buildings and tunnel projects.

| Model | HBTS 90 |

| Max. Output Capacity | 95m³/h |

| Max.Concrete Pumping Pressure | 20Mpa |

| Max. Vertical Conveying Distance | 360m |

| Distribution Valve Type | S valve |

| Diesel Engine Power | 199kW |

| Delivery Distance (Vertical/Horizontal) | 100-300m 300-1200m |

Concrete Trailer Pump

Concrete trailer pump is a kind of cost-effective equipment suitable for residential, commercial, and small to mid-scale construction sites.

| Models | HBT30/40/50/60/80/90 |

| Max. theo. concrete output | 30~90 m³/h |

| Max.concrete pumping pressure | 6~20 MPa |

| Distribution valve type | S valve |

| Diesel engine model | Yuchai/Weichai/Cummis |

| Diesel engine power | 52~199kW |

| Delivery Distance (vertical) | 100-300m |

| Delivery Distance (horizontal) | 300~1200m |

Truck-mounted Mixer Pump

Truck-mounted mixer pump is a combination of mixer and pump, providing mixing, transporting, and pumping in one unit.

| Model | HBCJ50-9-45ES |

| Concrete Output | 50 m³/h |

| Pump Pressure | 9 MPa |

| Main Motor Power | 45 kW |

| Mixer Model | JS500 |

| Main Oil Pump Model | 112L |

| Conveying cylinder*stroke | Φ200mm*1000mm |

| Max. aggregate diameter | Gravel 40mm / Pebble 50mm |

Lightweight Concrete Pump

Lightweight concrete pumps are designed to work with lightweight concrete mixes that require stable, uniform delivery.

| Property | Lightweight Concrete |

| Density | 300-1800 kg/m³ |

| Aggregate Type | Foam bubbles, perlite, expanded clay |

| Pump Pressure Requirement | 2-5MPa |

| Viscosity | Low to medium |

| Flow Stability | Sensitive to pressure and vibration |

| Typical Use | Roof insulation, void fillllig, block production |

Secondary Structural Pump

The mini concrete pump machine is specially designed for secondary structual jobs inside building structures, such as pouring colomns, walls and so on.

| Model | LT-8A Oblique Pump |

| Max. Theo.Concrete Output. | 8-10 m3/h |

| The Biggest Transportation (Vertical/Horizontal) | 30m/80-100m |

| Diameter of Delivering Pipe | 80mm |

| Max. Aggregate Diameter | 30mm |

| Rate Power of Diesel Engine | 25HP |

| Dimensions: length×width×height | 2500*1000*1500 mm |

| Total Weight | 780Kg |

Applications of Advanced Concrete Pumping in Modern Construction

The use of advanced concrete pumping has expanded across multiple sectors:

High-rise building construction requiring long-distance vertical pumping

Bridge, tunnels, and infrastructure projects

Large-volume foundation pours

Underground engineering and shaft construction

Precast concrete plants needing precise, clean concrete placement

Residential and commercial buildings

These applications benefit from better productivity and consistent concrete quality.

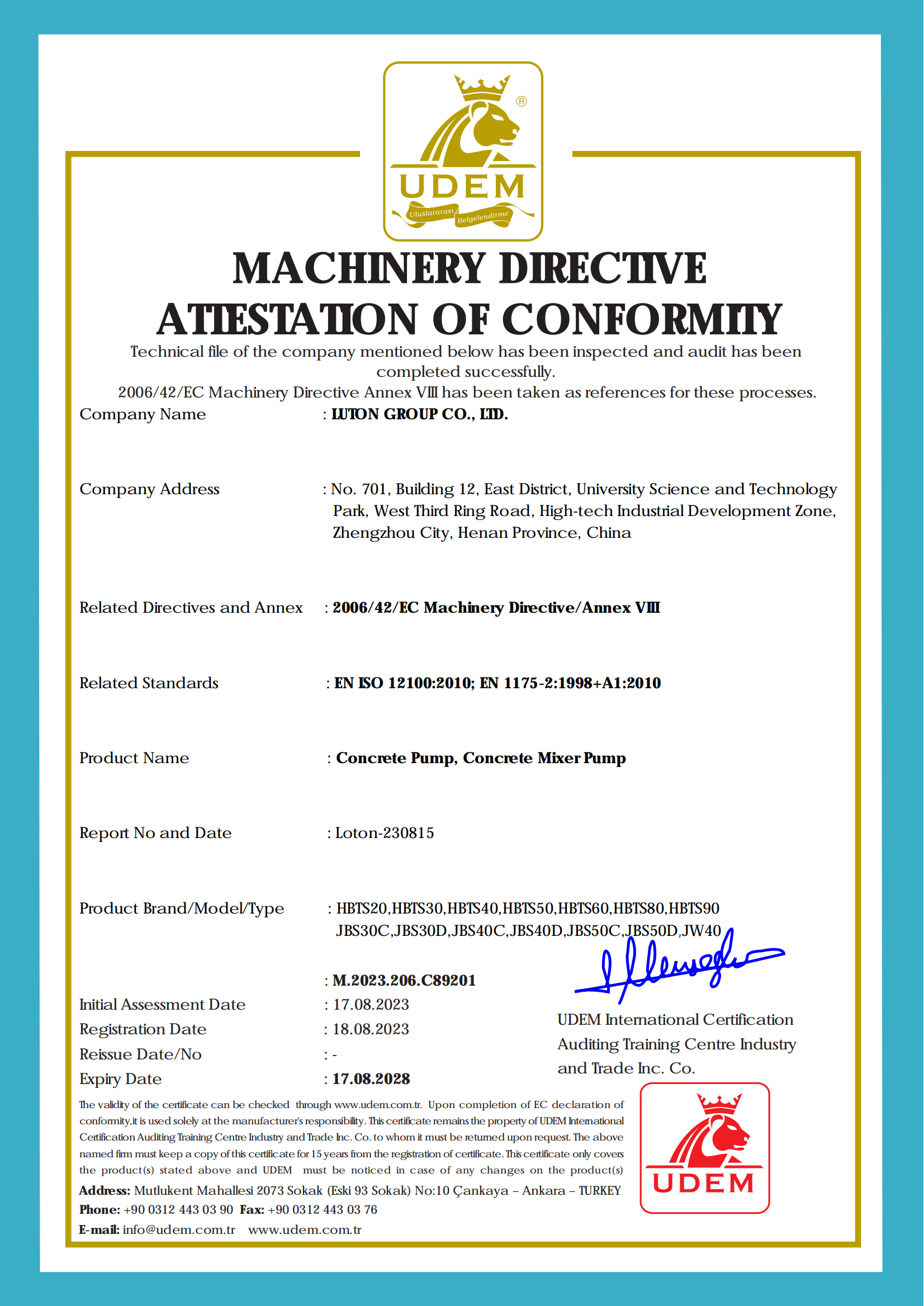

LUTON Advance Concrete Pumping Solutions

As a leading manufacturer of concrete machinery, LUTON provides a complete range of advanced concrete pumping equipment designed for global contractors:

Truck-mounted concrete pumps with advanced boom control

Trailer concrete pumps for high-pressure long-distance delivery

Concrete mixer pumps for flexible, mobile construction

Customizable pumping systems, designed for different concrete grades and project needs

LUTON machines deliver stable performance, wear-resistant components, energy efficient hydraulic systems, and intelligent monitoring options.

We also provide on-site training, 24/7 after-sales service, spare parts support, and competitive pricing to help contractors complete projects more efficiently.

How to Choose the Right Advanced Concrete Pump

To select the best advanced concrete pumping solution, consider the following factors:

Required pumping height and horizontal distance

Concrete type and aggregate size

Jobsite conditions (urban, rural, tunnel, slope)

Desired output capacity

Budget, operation cost, and maintenance requirements

Mobility level (fixed site vs. mobile projects)

A correct selection ensures higher efficiency and longer equipment lifetime.

FAQs About Advanced Concrete Pumping

Q1. What makes concrete pumping “advanced”?

It refers to high-pressure pumping, intelligent monitoring, precision boom control, and improved material durability that significantly enhance performance.

Q2. Can advanced pumping handle lightweight concrete?

Yes, but it requires a pump designed for lightweight mixes, ensuring uniform flow without blockages.

Q3. Is advance concrete pumping suitable for high-rise buildings?

Absolutely. Modern high-pressure pumps can deliver concrete to hundreds of meters vertically.

Q4. How often should an advanced pump be maintained?

Routine checks after every project and scheduled maintenance every 250-300 working hours are recommended.

Looking for reliable advanced concrete pumping equipment for your upcoming projects? Contact us for :

- Free quotation

- Technical consultation

- Product catalogs & specification sheets

- On-site video demonstration

Our experts will help you choose the best pump for your construction needs.