65 Meter Concrete Pump

Working on a large size commercial construction project, requiring a large quantity of concrete in a short time? 65-meter concrete pump is capable to deal with such projects with high maneuverability!

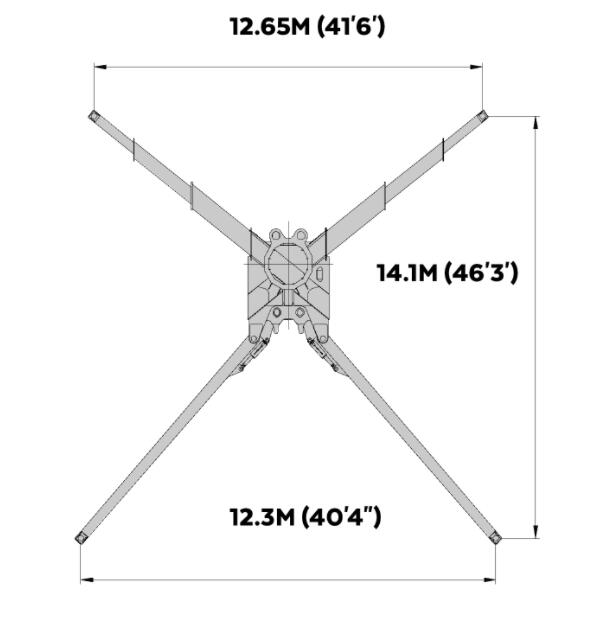

Luton’s long boom concrete pumps are upgraded with super X folding outriggers to ensure safety and enhance stability!

Low Maintenance Cost

Extremely High Productivity

Reach out to us to get a free quote!

Specifications of 65 Meter Concrete Pump

Here are 65-meter truck-mounted concrete boom pump standard specifications:

Boom Specification

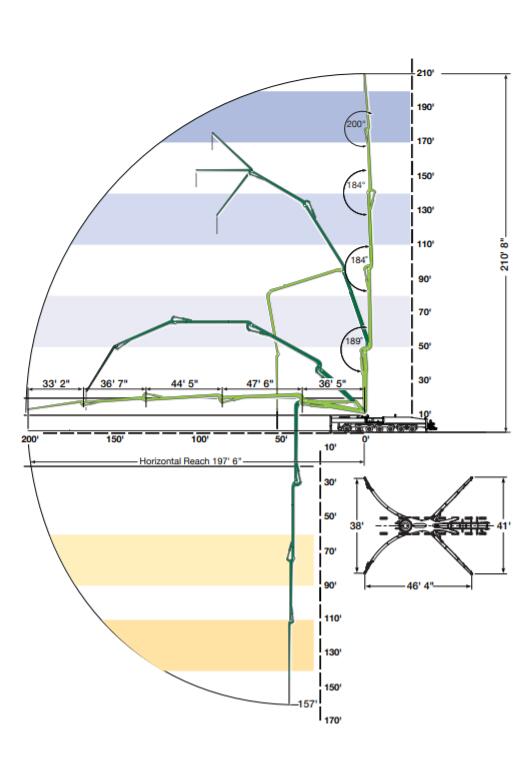

| Vertical Reach | 64.21 m |

| Horizontal Reach | 60.2 m |

| Reach from front of the Truck | 57.6 m |

| Unfolding Height | 17 m |

Pump Specification

| Max. Theoretical Output | 181 m3/h |

| Max. Pumping Pressure | 85 bar |

| Stroke Length | 2100 mm |

| Hydraulic System Pressure | 350 ba |

General Specification

| Wheelbase | 8,865 mm |

| Front-axle Weight | 25,524 kg |

| Rear-axle Weight | 25,342 kg |

| Water Tank | 780 L |

Loyal Services, Good Experience

Durable concrete boom pump

Fast and safe delivery

Only pay for what you get

Competitive price in China

Professional suggestions and help

Free after-sale service

Our Certificates and Honors

65 Meter Concrete Pump Truck Application

65 meter concrete boom pump is a type of placing concrete pump for house building in new rural area.

A 65 meter long boom pump truck is working on overhead bridge.

Features of 65 Meter Concrete Boom Pump

The 65-meter concrete pump truck has a super long placing boom. Compared to pump truck with short booms and concrete ground pump, it has some unqiue features for a better performance.

Also Read: Concrete Pump Long Boom

5 sections of unfolding booms

The fold and roll boom sections allow the main part to tilt away from the pouring, while manipulating the tip part above and below the barrier to go deeper into buildings than ever before.

Thanks to the 990 ° total joint, the operator can provide reliable concrete delivery inward, outward, upward and downward. Maximize your return on investment by making more gains from the long-term pumping business.

7-axles chassis

The super long boom concrete pump need a stable truck chassis. This truck pump has seven axles, as 3 axles in the front and 4 axels in the rear desingn.

For such a super long boom truck pump, the 7 axle chassis sometimes is not sturdy to support the boom, so, the boom has been extended to the top of the cab. By doing so, each boom can be prolonged 1-2meters after the second boom.

Upgraded hydraulic pumping system

Proper cooling of the hydraulic oil is essential for continuous operation under harsh conditions. Furthermore, filtering is the only most important way to keep the hydraulic system running smoothly.

That is why the new generation deisgn constantly sucks hydraulic oil from the tank and circulates it through filters and efficient coolers.

This independent hydraulic circuit continues to provide protection and performance, even if the concrete pump is not engaged.

Big rock vavle

It is necessary for all long boom pumps, and optional for other models. It extends the valve to easily meet high capacity pouring requirements even under the most demanding mixing conditions.

The patented design allows the big rock valve to be automatically adjusted to maintain pressure on the concrete for long-term operation without failure.

Is Concrete Super Long Boom Pump Good to Use?

Concrete pump boom truck can deal with the delivery and concrete placement operation on site at the same time.

With the characteristics of excellent pumping performance, wide cover areas, flexible mobility and convenient transfer, the long placing boom is applicable for many large size of concstructions.

Meanwhile, the 65 meter concrete super long boom is especially suitable for concrete pouring demand of large, super large volume, ultra-thick foundation concrete once-pouring and high quality requirements.

In the concrete construction of national major construction projects, concrete pump truck pumping technology is adopted, and its use scope has been throughout water conservancy, subway, bridges, large foundation, high-rise buildings and other projects.

In recent years, the concrete long boom pump truck has become the preferred model of pumping concrete construction machinery.

Here is one thing to note. The boom length of the pump truck depends on the model of your pump truck. If the delivery arm is lengthened randomly, the pumping pressure is likely not to be enough to pump concrete.

Classfications of Super Long Boom Pump Truck

Different pump trucks will be designed according to the requirements of the chassis length, width and height, the mixer efficiency requirements, the arm rack length requirements, etc.

Length of the placing boom

According to the height of the pump truck with long booms, the concrete pump truck can be divided into: short boom pump truck, long boom truck, super long boom truck.

Usually the arms frame length of 13 – 28 meters for short boom, 31 – 47 meters for long boom, and 51 – 62 meters for ultra-long boom.

At present, the most common pump trucks on the market are mostly short booms and long boom trucks.

Output capacity

Depending on the size of the delivery output, the pump truck can be divided into three models, such as small pump truck with out put of 44 – 87 m3/h, medium 90 – 130 m3/h, large 150 – 204 m3/h.

Placing boom sections

Depending on the number of boom segments, the pump truck can be divided into four forms: 2 boom sections, 3 boom sections, 4 boom sections, 5 boom sections, 6 boom sections, and 7 boom sections.

More popular models in the market are 2 boom sections, 3 boom sections, 4 boom sections and 5 sections.

Common Problems of Concrete Pump During Work?

There are two major problems may occur during concrete pumping work:

- Concrete Blockage

Concrete blockage often occurs at the end of the pipeline, which can be observed on the pressure gauge in form of an increasing pressure. The causes includes improper selection of pump equipment, gap-graded aggregates, lack of pipeline maintenance, wrong water/concrete ratio and loss of workability at the construction site and so on.

- Segregation and bleeding in concrete mixture

Segregation is the separation between cement paste and aggregate during the handling with concrete. It occurs when pumping pressure overcomes the adhesion force in the concrete mix.

Bleeding is the water escape of the concrete mixture due to the bad proportions of concrete mix and the use of gap-graded aggregate.

How to avoid these concrete pumping problems?

- Use well-graded aggregate with proportion concrete constituents property.

- Evenly and thoroughly mix concrete materials.

- Add lubricate constituents to facilitate pumping process.

- Correct and improve labor skills.

- Use suitable concrete pumping equipment.

- Choose the pipes whose inner diameter is at least three times of the maximum aggregate size to avoid the risk of blockage near bend points.

- Thoroughly clean the pipeline after each work.

For more working faults, welcome to contact LUTON GROUP.

Get A Free Quote

Mobile:

0086-173-2016-6678

Whatsapp:

0086-173-2016-6678

Email:

sales@ltconcretepump.com