High rise building construction is one of the most demanding sectors in the construction industry. Delivering concrete to heights above 50m is not only technically challenging but also requires equipment that gurarantees consistency, safety and speed. Traditional methods such as cranes, buckets, or manual labor are often inefficient, time-consuming, and unable to meet the quality standards required in modern projects.

This is where a concrete pump for high rise building construction becomes indispensable. By using high-pressure pumping systems, contractors can transport large volumes of concrete vertically and horizontally with minimal effort. Whether for residential towers, office complexes, or skyscrapers, a high rise concrete pump ensures that concrete reaches the top floors efficiently, maintaining its quality and workability throughout the process.

Overcoming Vertical Pumping Challenges

Maintaining Concrete Quality

Continuous And Efficient Operation

Adaptability To Complex Structure

Space And Labor Saving

Why High Rise Projects Need Specialized Concrete Pumps

High rise construction presents unique challenges that standard concrete delivery methods cannot overcome. As buildings climb higher, the demand for more powerful, efficient and reliable equipment becomes essential. A concrete pump for high rise building construction addresses these challanges form multiple angles:

Overcoming Vertical Pumping Challenges

Skyscrapers often require vertical pumping heights of 50-200 meters or more. Traditional cranes and buckets cannot deliver such volumes efficiently, while specialized high-pressure concrete pumps ensure smooth and uninterruped pumping at extreme heights.

Maintaining Concrete Quality

Concrete used in tall structures usually has strict requirements for workability and strength. High rise concrete pumps preserve slump, prevent segregation, and minimize blockages, ensuring consistent concrete quality throughout the pipelline.

Continuous And Efficient Operation

Large-scale pours, such as core walls, slabs, and shear walls, must be completed quickly to maintain structural integrity. High rise pumps provide a steady and uninterrupted flow of concrete, allowing each section to be poured within the optimal time window.

Adaptability To Complex Structures

Modern high rise buildings feature intricate designs with columns, beams, and core structures located in hard-to-reach areas. A stationary concrete pump with a placing boom can precisely deliver concrete where needed, improving accuracy and reducing waste.

Space Optimization On Urban Sites

Construction sites in city centers are often congested and leave little room for large equipment. By positioning a stationary pump on the ground and connecting it to vertical pipelines, contractors save valuable space while keeping the worksite organized.

Labor And Cost Reduction

Using concrete pumps minimizes reliance on cranes and manual labor, leading to significant savings in manpower. Contractors also benefit from reduced crane usage, lower operating costs, and faster project timelines.

Enhanced Safety Standards

Hoisting concrete buckets hundreds of meters above ground creates unnecessary risks. A pump system eliminates this hazard by delivering concrete directly through pipelines, protecting workers and improving overall jobsite safety.

Energy Efficiency And ROI

Specialized high-pressure systems are designed for high efficiency, reducing overall energy consumption compared to traditional lifting methods. Although initial investment may be higher, contractors gain long-term returns through shorter project cycles and lower labor costs.

Compliance With Modern Construction Standards

Many global construction codes now encourage or mandate mechanized concrete placement for high rise projects. Using a high rise concrete pump not only ensures compliance but also enhances a company’s reputation for quality and professionalism.

High rise projects demand equipment that combines power, precision, and reliability. Specialized concrete pumps deliver on all these fronts, making them the backbone of modern tall buildiong construction.

Types Of Concrete Pumps For High Rise Building Construction

Not all concrete pumps are suitable for high rise buildings projects. Contractors need to carefully select the right type of pump based on the building height, site conditions, and concrete demand. Below are the most commonly used types of high rise concrete pumps.

Trailer Concrete Pumps (Stationary Concrete Pumps)

Typical Models – HBT60, HBT80, HBT90, HBT100

Application – Residential towers (20-40 stories), office buildings, and mixed-use high rises.

Features

- Compact size, easy to set up in limited spaces.

- Capable of pumping vertically up to 200m and horizontally up to 1000m.

- High pumping pressure (13-20MPa), suitable for dense, high-strength concrete.

| Model | HBT60-13-129R | HBT80-16-176R | HBT90-22-199R | HBT100-20-199R |

| Output Capacity (m³/h) | 67/45 | 84/45 | 90/57 | 100 |

| Pumping Pressure (MPa) | 13 | 16 | 22 | 20 |

| Distribution Valve | S | S | S | S |

| Engine Model | Weichai 129kW | Weichai 176kW | Weichai 199kW | Weichai 199kW |

| Conveying Distance (m) | 180/1000 | 260/1200 | 300/1200 | 300/1200 |

Truck-Mounted Concrete Pump With Boom

Boom Lengths – 36m, 42m, 56m, 63m (depending on model)

Application – High rise projects requiring frequent rolocation or flexible concrete placement, especially for slabs and columns at different floors.

Features

- Integrated placing boom for flexible concrete distribution.

- High output capacity, suitable for large-scale pours.

- Faster setup compared to stationary pumps.

| Model | Unit | LTB40R-15 | LTB40R-21 |

| Output capactiy | m³/h | 40 | 50 |

| Pumping pressure | Mpa | 10 | 10 |

| Distribution valve type | s valve | s valve | |

| Concrete cylinder | mm | Ф180×1300 | Ф180×1300 |

| Hopper capacity | L | 500 | 500 |

| Outlet diameter | mm | Ф150 | Ф150 |

| Vertical height of boom | m | 15.4 | 22 |

| Radius of place concrete | m | 13-16 | 20 |

| Concrete pipe | m | 125×3 | 125×3 |

| Tower rotation angle | ° | 200° | 200° |

| Leg open width | m | 5.5 | 5.5 |

| Diesel engine model | Weichai 82kW | Weichai 82kW | |

| Travelling diesel engine | Changchai L32 32HP | Changchai L32 32HP | |

| Max.aggregate diameter | mm | 30 | 30 |

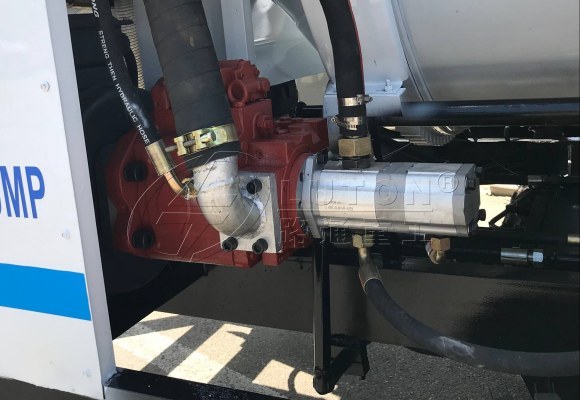

Specialized High-Pressure Pumps

Application – Super high-rise towers, skyscrapers, and projects with extreme vertical pumping requirements.

Features

- Designed specifically for ultra-tall buildings (above 200m).

- Reinforced S-valve and hydraulic system for stable operation.

- Handles long pumping pipelines without loss of efficiency.

Performance Comparison Of Common Models

| Pump Type | Typical Models | Max Output (m³/h) | Max Pressure (MPa) | Vertical Reach | Best For |

| Trailer Concrete Pump | HBT60 HBT80 HBT90 HBT100 | 60-100 | 13-20 | Up to 200m | Medium to residential towers |

| Truck-mounted Pump (Boom Pump) | 36m 42m 56m 63m | 80-150 | 8-12 | Depends on boom length | Large pour placement rises |

| Specialized High-pressure Pump | HP Series | 80-120 | 18-22 | 200m+ | Ultra high-skyscrapers, core wall construction |

By comparing these options, contractors can match the right high rise concrete pump with their project needs. For example, a 20-30 story tower may only require an HBT80 trailer pump, while a 60+ story skyscraper would need a specialized high-pressure pump with reinforced components.

Case Study – 20-story Residential Tower With HBT80 Trailer Concrete Pump

In a 20-story residential project, the contractor faced challenges of pumping concrete over 60 meters vertically within a tight urban site. The HBT80 trailer concrete pump was selected for its high output (84 m³/h) and strong pumping pressure (16 MPa), making it ideal for high rise building construction.

Installed at ground level and connected to vertical pipelines, the pump consistently delivered 70-80 m³ of concrete per day without blockages. Compared with traditional crane methods, the contractor achieved:

- 30% labor cost savings

- 25% faster project completion

- Reliable, continuous concrete delivery to upper floors

The project manager praised the HBT80 as a reliable and efficient high rise concrete pump that kept the project on schedule.

Performance Comparison Different Pump Models

Different high rise projects require different pumping capacities. Choosing the right high rise concrete pump ensures smooth construction progress, cost savings, and reliable performance. Below is a quick comparison of commonly used stationary trailer pumps for tall buildings.

Trailer Concrete Pumps (Stationary Pumps)

| Model | Max Output (m³/h) | Max Pressure (MPa) | Vertical Distance | Best For |

| HBT60 | 60 | 13 | Up to 120m | Mid-rise apartments, 10-15 floors |

| HBT80 | 84 | 16 | Up to 200m | Residential towers, 15-30 floors |

| HBT90 | 90 | 18 | Up to 220m | Office buildings, 25-40 floors |

| HBT100 | 100 | 20 | 250m+ | High-rise complexes, 40+ floors and skyscrapers |

Highlights: Stationary pumps are compact, powerful, and reliable, making them the most common choice for high rise building construction.

Truck-Mounted Boom Pumps

| Boom Length | Max Output (m³/h) | Max Pressure (MPa) | Reach Capability | Best For |

| 36m-42m | 80-120 | 8-10 | Up to mid-rise levels | Slabs, podiums, lower floors |

| 56m-63m | 120-150 | 9-12 | Extended reach | Mixed-use high rises, flexible placement |

Highlights: Boom pumps combine pumping and placing in one machine. They are faster to set up and ideal for projects requiring frequent relocation or precise placement, especially in podiums, slabs, and lower-to-mid sections of tall buildings.

Specialized High-Pressure Pumps

| Model | Max. Output (m³/h) | Max Pressure (MPa) | Vertical Distance | Best For |

| HP80 | 80 | 18-20 | 200-250m | Tall office towers, 40+ floors |

| HP100 | 100 | 20-22 | 250-300m | Super high-rise skyscrapers |

Highlights: Designed for extreme vertical pumping, these pumps use reinforced hydraulic systems and wear-resistant components. They are the go-to choice for skyscrapers and projects requiring pumping above 200 meters.

Key Takeaways

- Trailer concrete pumps (HBT series) – Best balance of power, cost and reliability for most high rise residential and office projects.

- Truck-mounted boom pumps – Offer flexibility and efficiency for slab pours and podium levels but are limited in vertical pumping heights.

- High-pressure specialized pumps – The ultimate solution for super tall buildings and demanding core-wall construction above 200m.

By combining these options, contractors can select the most suitable high rise concrete pump for sale based on project height, site layout, and concrete requirements.

Cost And Efficiency Benefits Of Using Concrete Pumps In High Rise Projects

One of the main reasons contractors invest in a concrete pump for high rise building construction is the significant cost and efficiency advantages it provides. Compared with traditional concrete delivery methods such as cranes and manual handling, high rise concrete pumps deliver measurable savings:

- Reduced Labor Costs – A stationary concrete pump eliminates the need for large crews to transport and place concrete manually. Contractors report up to 30-40% savings in labor expenses, especially on projects requiring continuous concrete supply.

- Faster Project Completion – Time is money in construction. With high pumping capacities and uninterrupted concrete flow, projects can be completed 20-30% faster, keeping developers ahead of schedule and reducing costly delays.

- Lower Crane and Equipment Expenses – Using cranes to lift concrete buckets not only slows down the process but also occupies valuabel crane time needed for other tasks. By switching to a high rise concrete pump, contractors reduce crane dependency and optimize resource allocation.

- Enhanced Material Utilization – Pumps minimize spillage, segregation, and delays that often occur with manual handling. This results in higher material efficiency and consistent quality, lowering the need for costly rework.

- Energy and Maintenance Savings – Modern pumps are engineered with efficient hydraulic systems and durable components. This reduces energy consumption per cubic meter of concrete pumped, while extending equipment service life and lowering long-term maintenance costs.

Investment Value And ROI

While purchasing or renting a concrete pump for sale involves an initial investment, the return on investment (ROI) is quickly realized through labor reduction, shorter timelines, and improved construction quality. For high rise projects, these benefits often outweigh the costs within just one or two projects.

In short, a high rise concrete pump is not just a piece of equipment – it is a productivity multiplier that drives cost efficiency, improves safety, and ensures timely project delivery.

Customer Feedback & Industry Recognition

Real project cases show the value of using a concrete pump for high rise building construction. A customer from Nigeria selected the HBT80 trailer concrete pump for a 20-story residential project in Lagos.

The HBT80 concrete pump was a game changer for our high rise project. It pumped concrete smoothly to more than 70m height every day without any delays. We saved significant labor costs and managed to complete each floor ahead of schedule.

Project Manager

Mr. Samuel Adewale

Our high rise concrete pumps are now widely recognized across Asia, the Middle East, and Africa for their reliable performance, ability to handle high-strength concrete, and strong after-sales support.

Why Choose Our High Rise Concrete Pump Solutions

Selecting the right high rise concrete pump is critical for tall building projects. Our product line covers stationary trailer pumps, truck-mounted boom pumps, and high-pressure concrete pumps, giving contractors flexible options for different site conditions.

Key Advantages of LUTON High Rise Concrete Pump Solutions

- Full Range Of Models: From compact HBT60 pumps for mid-rise buildings to HBT100 and high-pressure pumps for skyscrapers.

- Proven Reliability: Durable S-valve system and advanced hydraulics minimize downtime.

- Versatility: Suitable for residential towers, commercial complexes, and high-rise infrastructure.

- Strong Support: Professional after-sales service and readily available spare parts ensure smooth project execution.

By offering tailored solutions, we help contractors achieve higher efficiency, lower costs, and timely completion in every high rise concrete pumping project.

Conclusion

A concrete pump for high-rise building construction is the most efficient solution for delivering concrete at great heights. With a full range of stationary, boom, and high-pressure pumps, we provide the right equipment for every tall building project.

Contact us today for specifications, competitive pricing, and expert advice on choosing the best high rise concrete pump for your construction needs.

Export Case Of LUTON Concrete Pumps

HBTS30 Concrete Pump Sold To Panama

HBTS40 Concrete Pump To Ethiopia

Concrete Pump In Pakistan

Concrete Pump Indonesia

Concrete Pumps In India

Concrete Trailer Pump For Sale Australia

HBT90 Diesel Concrete Trailer Pump To Armenia

Concrete Mixer Pump Exported To Sierra Leone

Concrete Mixer Pump Exported To Kenya

LUTON Concrete Trailer Pump To Brunei

Concrete Trailer Pump To Jamaica